Anti-radiation silicone rubber sealing gasket and preparation method thereof

A technology of silicone rubber and gaskets, which is applied in the field of rubber gaskets, can solve the problems of poor radiation resistance and easy failure of sealing performance, and achieve the effects of good high and low temperature resistance and excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

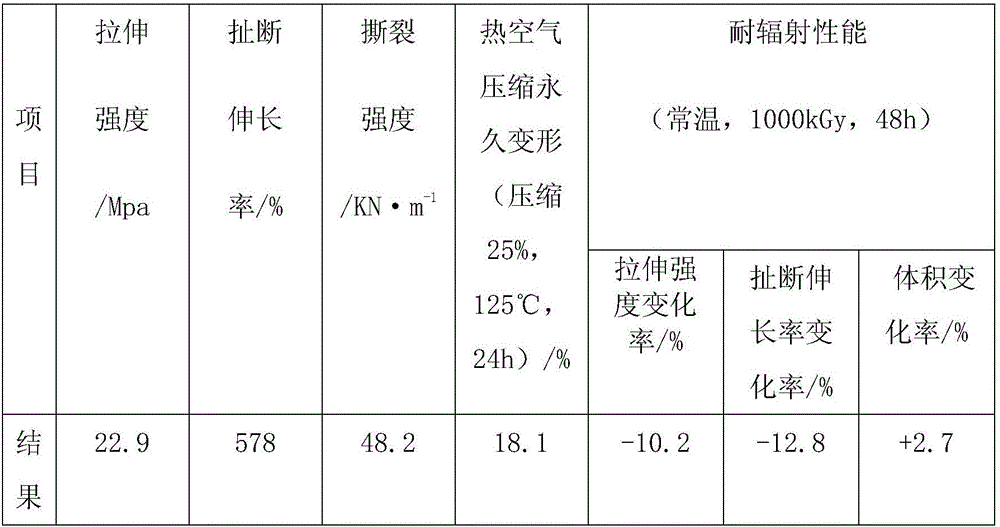

Examples

Embodiment Construction

[0014] A radiation-resistant silicone rubber gasket, made of the following raw materials by weight (kg): methyl vinyl trifluoropropyl silicone rubber 32, hydrogenated nitrile rubber 26, ceramic polishing waste 24, polyaminobismaleimide Amine 5, 2,4-dichlorobenzoyl peroxide 3.5, cadmium stearate 1.5, polyethylene wax 4, antimony pentasulfide 6, ethylene glycol dimethacrylate 5, nano barium sulfate 16, polyhexyl Neopentyl glycol-1,6-hexanediol diol 13, terpene-styrene resin 8, accelerator TBBS2.5, anti-aging agent BLE2, modifier 10;

[0015] The preparation method of the modifying agent is as follows: (1) take the following raw materials in weight (kg): sea ball stone 16, needle coke 10, polymerized ferrophosphorus powder 12, nanometer aluminum titanate 8, methylene dinaphthalene sulfonate Sodium sulfosuccinate 3, sodium dioctyl sulfosuccinate 2, cetearyl glucoside 1.5, polypropylene glycol 2005, tri-n-butylamine 4, octyldodecanol mescemate 3; (2) take sea balls Stone and needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com