A kind of petal-shaped cuprous oxide and its preparation method and application

A cuprous oxide and petal-shaped technology, which is applied in the field of petal-shaped cuprous oxide and its preparation, can solve the problems of large power or heat consumption, complicated operation, etc., and achieve the effect of low cost, simple operation and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The construction of embodiment 1 photocatalytic fuel cell

[0027] TiO in this example 2 / ITO electrode, prepared by the following method:

[0028] (1) Weigh 30mg of P25 titanium dioxide and ultrasonically disperse in 2mL of ethanol for one hour, take 1mL of the dispersion and use the pulling method to obtain TiO 2 / ITO electrode;

[0029] (3) TiO 2 / ITO electrodes are placed in an oven and dried at a constant temperature of 35-45°C to obtain TiO 2 / ITO electrode.

[0030] The construction of the photoelectrochemical fuel cell of the present embodiment, the specific operation steps are as follows:

[0031] TiO prepared as above 2 The / ITO electrode is used as the anode, and the ITO electrode is used as the cathode, which are respectively connected to the working electrode terminal and the reference electrode terminal of the workstation; add 0.1mol / L sodium sulfite solution (the pH value of the electrolyte solution is 11-14) in the anode pool, and add Glucose (fue...

Embodiment 2

[0032] Example 2 Photocatalytic fuel cell driven reduction deposition of cuprous oxide

[0033] Elucidate the TiO in the photocatalytic fuel cell that embodiment 1 builds 2 The current process of depositing cuprous oxide on / ITO electrode and ITO electrode, the specific operation steps are as follows:

[0034] (1) TiO prepared in Example 1 2 The / ITO electrode is used as the anode, and the ITO electrode is used as the cathode, which are respectively connected to the working electrode terminal and the reference electrode terminal of the workstation; add 1.5mL of sodium sulfite solution with a concentration of 0.1mol and a pH value of 12 into the anode pool, and add glucose ( fuel) to make its concentration 1.0mol / L; then add 5mL, 0.1mol / L copper acetate solution to the cathode pool, keep the solution in the anode pool at 25°C with a constant temperature water bath, and the deposition time is 9000s;

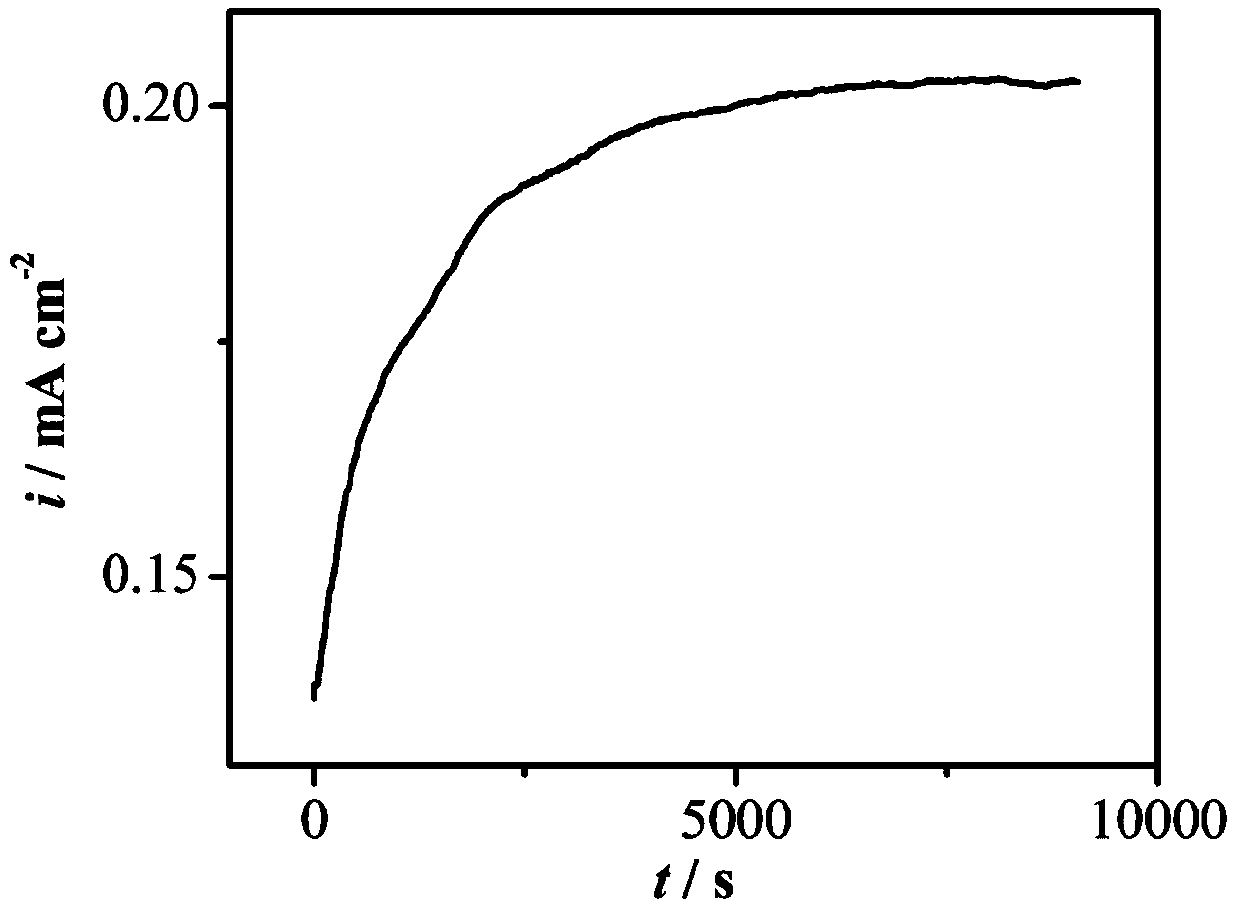

[0035] (2) Utilize the electrochemical workstation to measure the photocurre...

Embodiment 3

[0037] Effect of UV radiation and fuel on cuprous oxide deposition in embodiment 3 photocatalytic fuel cell

[0038] To the test of the photocatalytic fuel cell performance that embodiment 1 builds, concrete operation steps are as follows:

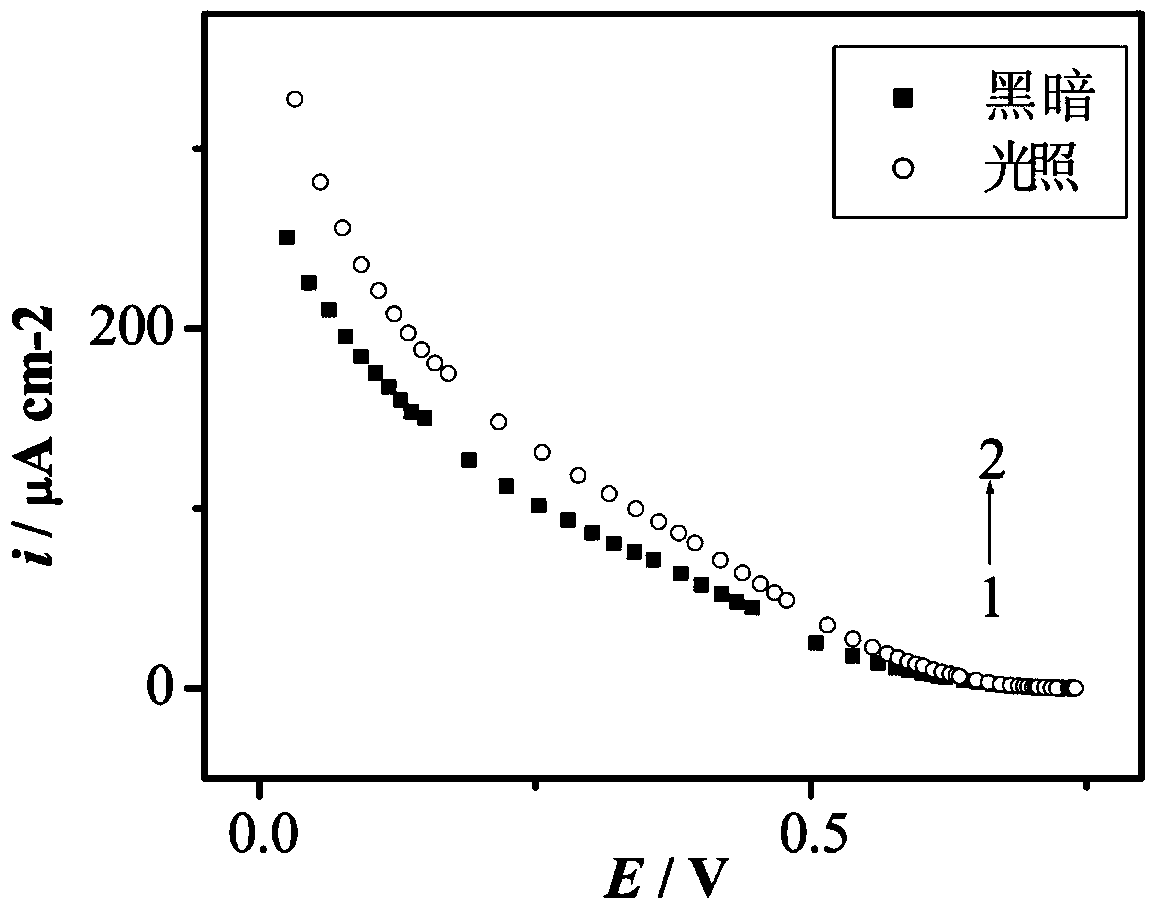

[0039] Measure the current and power diagrams under dark and light conditions respectively, adjust the resistance value of the resistance box connected between the anode and cathode of the photocatalytic fuel cell, measure and calculate the change curve of the current density and power density of the photocatalytic fuel cell with voltage, and the result Such as image 3 with 4 shown. Under dark conditions, the short-circuit photocurrent density of the fuel cell in the photocatalytic fuel cell constructed in Example 1 is 250.6 μA cm -2 , with a maximum power density of 26.2 μW cm at 0.3 V -2 , under ultraviolet light irradiation, the short-circuit photocurrent density of the photocatalytic fuel cell constructed in Example 1 is 327μA·cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com