Activated graphene/needle-shaped nickel hydroxide nanocomposite material and preparation method thereof

A nanocomposite material, nickel hydroxide technology, applied in nanotechnology, nanotechnology, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problem of low conductivity of transition metal hydroxides, insufficient energy density of capacitors, and incapable electronic Rapid transfer provides support and other issues to achieve the effects of excellent electrochemical performance, easy process control, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

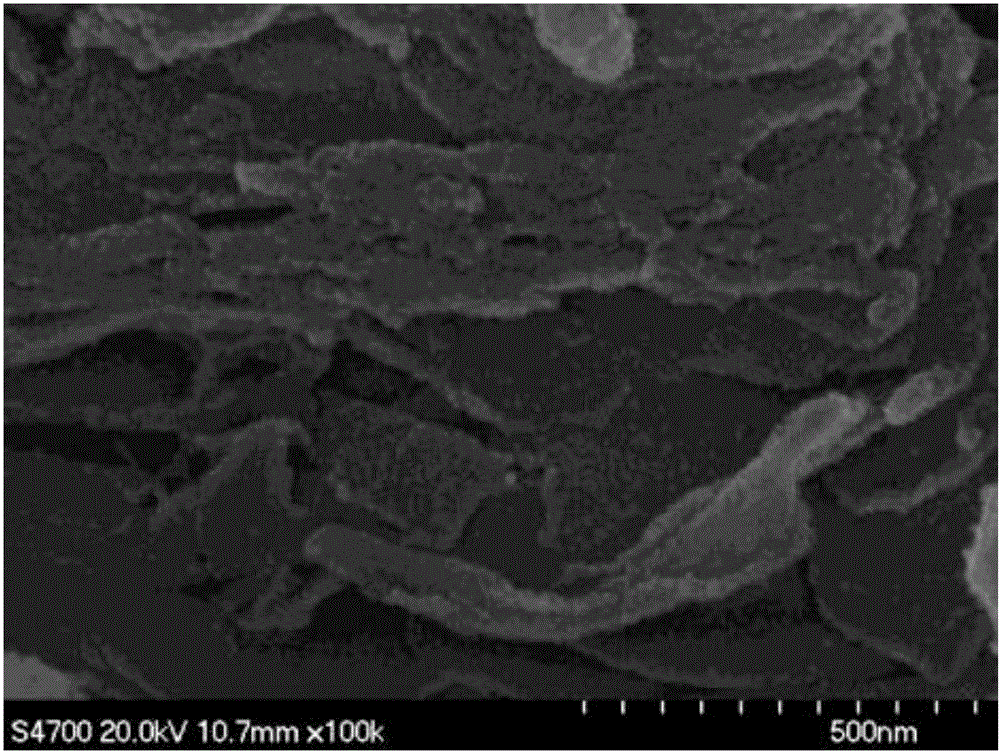

[0033] First weigh 1.5g of NaNO 3 The solid was dissolved in 69ml of 98% concentrated sulfuric acid, and the mixed solution was placed in an ice-water bath while magnetically stirring for 15min to make the NaNO 3 The solid is fully dissolved (the reaction temperature is controlled at 0°C); weigh 3.0g of natural graphite and add it to the above mixed solution, and stir for 15min (the temperature is also maintained at 0°C); then, slowly add a certain amount of potassium permanganate, During the addition process, control the reaction temperature not to exceed 20°C, stir for 20 minutes, adjust the temperature to 35°C and continue stirring for 1 hour; then add 138ml of deionized water to the mixture and raise the temperature to 98°C, stir for 15 minutes, and then add 420ml of deionized water ionized water and add 30ml of 30% H 2 o 2 To reduce the residual oxidant, the solution turns bright yellow; turn off the heating and filter while hot, while filtering, wash with 5% hydrochlor...

Embodiment 2

[0043] The preparation steps of graphene are as embodiment 1. Dissolve 1g NaOH in 100mL deionized water, add 1g graphene into the NaOH aqueous solution, fully stir and dry, put the mixture of graphene and NaOH in a nickel dry pot, put it into an activation furnace, and carry out in a nitrogen atmosphere. Activation, heating up to 800°C at a heating rate of 2°C / min, stopping heating after 2 hours of heat preservation and cooling naturally, washing with dilute hydrochloric acid and deionized water to pH = 7 after activation, and obtaining activated graphene after drying.

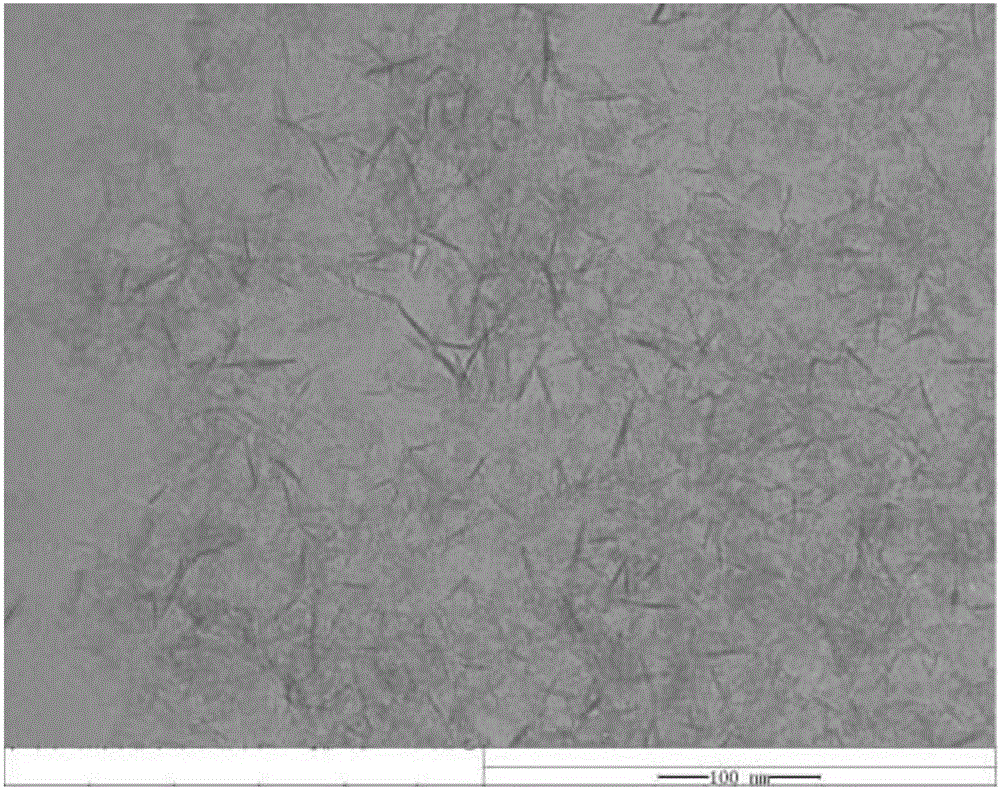

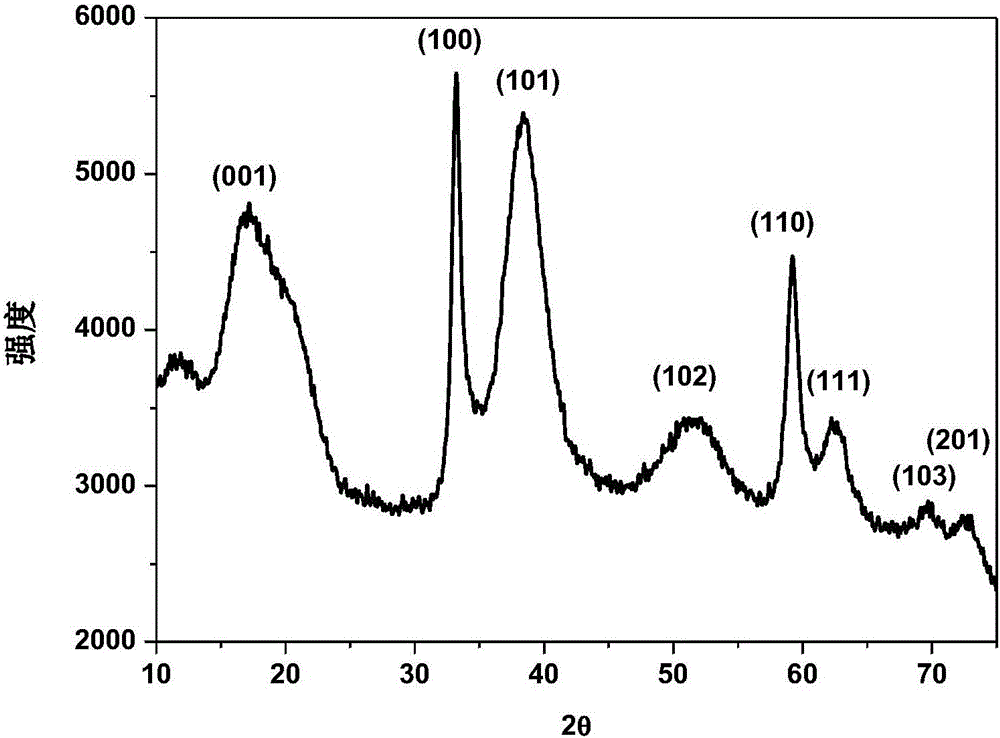

[0044] According to the mass ratio of activated graphene and the corresponding nickel element in the activated graphene / acicular nickel hydroxide nanocomposite material is 1:0.634 ratio, 0.31g nickel nitrate is dissolved in 200mL deionized water, 0.1g activated graphene Add it to nickel nitrate aqueous solution and ultrasonically disperse for 30 minutes. Add 1mol / L KOH aqueous solution dropwise to the above-m...

Embodiment 3

[0047] The preparation steps of graphene are as embodiment 1. Dissolve 5g KOH in 100mL deionized water, add 1g graphene into the KOH aqueous solution, fully stir and dry, put the mixture of graphene and KOH in a nickel dry pot, put it into an activation furnace, and carry out in a nitrogen atmosphere. Activation, heating up to 800°C at a heating rate of 2°C / min, stopping heating after 2 hours of heat preservation and cooling naturally, washing with dilute hydrochloric acid and deionized water to pH = 7 after activation, and obtaining activated graphene after drying.

[0048] According to the mass ratio of activated graphene and the corresponding nickel element in the activated graphene / acicular nickel hydroxide nanocomposite material being 1:1.90, 0.77g of nickel chloride was dissolved in 200mL of deionized water, and 0.1g of activated graphite Alkene was added to nickel nitrate aqueous solution, and ultrasonically dispersed for 30 minutes. Add 1 mol / L NaOH aqueous solution d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com