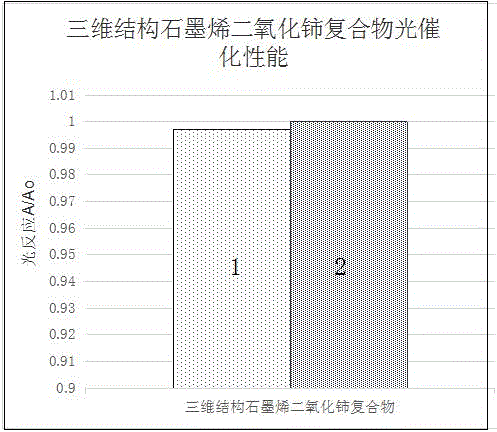

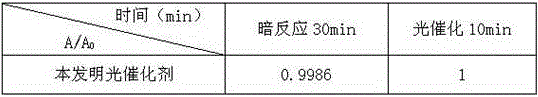

Three-dimensional porous structure graphene-cerium dioxide composite photocatalyst

A three-dimensional porous, cerium oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc. The low utilization rate of visible light and other problems can achieve the effect of high light utilization efficiency, stable photocatalytic performance and continuous photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the mixture of 500mg graphite powder and 2.0g sodium nitrate, add 18 ml of concentrated sulfuric acid with a mass concentration of 98%, and stir the reaction for 1 hour at a temperature lower than 5 °C; after that, slowly add it to the reactor within 0.5 hours 3.0g of potassium permanganate powder was reacted for 1.5h at a temperature less than 5°C; the above reaction system was heated to 35°C, kept for 1h, and 40ml of deionized water was added to the reactor after the heat preservation, and then the temperature was raised to 100°C Then, the reaction product was cooled to room temperature, 70 milliliters of deionized water were added to dilute, and then 10 milliliters of hydrogen peroxide solution with a mass concentration of 35% was added to it; Washed with 400 ml of 5% hydrochloric acid three times, then washed with deionized water three times, and finally dialyzed the filter cake with a dialysis bag for two days, then vacuum-dried at 60 ° C for 24 hours, and obtain...

Embodiment 2

[0034] The graphene oxide obtained in Example 1 was weighed to prepare a graphene oxide dispersion, and then a three-dimensional structure of graphene-ceria composite was prepared.

[0035] Preparation of three-dimensional graphene-titania composites

[0036] Disperse 60 mg of graphene oxide obtained in Example 1 in 20 milliliters of deionized water, and sonicate for 2 h; dissolve 60 mg of cerium trichloride into 10 milliliters of water, add it to the above-mentioned graphene oxide dispersion, and then use Pipette pipetting mass concentration is that 100-800 microliters of 28% ammonia water is added therein, and after ultrasonic treatment reaction mixture, put into polytetrafluoroethylene lined autoclave again, react 12 hours at 180 ℃ of temperature, obtain After the hydrogel product is freeze-dried, a three-dimensional graphene-ceria composite photocatalyst is prepared.

Embodiment 3

[0038] The graphene oxide obtained in Example 1 was weighed to prepare a graphene oxide dispersion, and then a three-dimensional structure of graphene-ceria composite was prepared.

[0039] Preparation of three-dimensional graphene-ceria composites

[0040] Disperse 120 mg of graphene oxide prepared in Example 1 in 40 milliliters of deionized water, and ultrasonically treat it for 2.5 h; dissolve 120 mg of cerium trichloride into 20 milliliters of water, add it to the above-mentioned graphene oxide dispersion, and then Pipette the mass concentration with a pipette to be 300 microliters of 28% ammonia water and add it, after ultrasonic treatment of the reaction mixture, put it into a polytetrafluoroethylene lined autoclave again, and react at 180 ° C for 12 hours, the obtained hydrogel After the product is freeze-dried, a three-dimensional graphene-ceria composite photocatalyst is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com