Graphene nano composite material with dual intelligent responsivities

A nanocomposite material and graphene technology, which is applied in the field of graphene nanocomposite materials and its preparation, can solve problems such as easy agglomeration and graphene application limitations, and achieve the effect of good dispersion and intelligent responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (purification of N-isopropylacrylamide)

[0037] Weigh 5.0013g of NIPAM (N-isopropylacrylamide) monomer into a 100ml two-necked round-bottomed flask, heat and drop acetone until NIPAM is completely dissolved, cool to reflux, add dropwise n-hexane, the added acetone and n-hexane The amount of its volume ratio is about 1:6, stop heating. After the product is cooled to room temperature, transfer it to the refrigerator, cool and precipitate crystals, place it in the upper layer of the refrigerator at 5°C for 10 hours, and transfer it to the lower layer of the refrigerator at -15°C for 20 hours. After the crystals were precipitated, they were taken out for suction filtration and washed with n-hexane. Store in a desiccator after vacuum drying at room temperature.

Embodiment 2

[0038] Embodiment 2 (ionic liquid 1-vinyl-3-ethylimidazolium bromide (ViEtIm + Br - )Synthesis)

[0039]Measure 6.0mL of 1-vinylimidazole and 8.5mL of ethyl bromide respectively, add them to a 100mL round bottom flask in turn, heat to reflux for reaction, and set the reaction temperature of the oil bath to 70°C. After 1 hour of reaction, white turbidity appeared, and the reaction was continued until the turbidity disappeared, and the reactant became solid. Continue the reflux reaction for 10h, and stop heating when the reflux is not obvious. The reactant was poured into a beaker, recrystallized three times with acetonitrile-ethyl acetate, and dried in vacuo to obtain a yellow-white solid powder.

[0040]

Embodiment 3

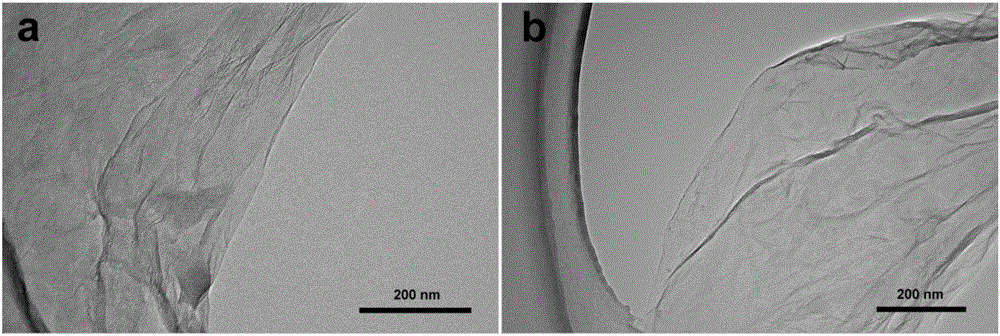

[0041] Embodiment 3 (preparation and characterization of graphene oxide GO)

[0042] Add 67.5mL of concentrated sulfuric acid to the three-necked round-bottomed flask, place it in an ice-water bath, then add 2.0005g of high-purity graphite and 1.5878g of NaNO to the round-bottomed flask 3 , after stirring well, slowly add 9.0037g of solid KMnO 4 , During the process of adding medicines, keep the temperature in the round bottom flask always controlled below 5°C, and then react at 32-38°C for 30 minutes. When the reaction was nearing the end, the black suspension turned into a taupe viscous substance, which was left at room temperature for 7 days. Finally, dilute with 560.0mL of hot water and add 3% H 2 o 2 Restore the remaining high-valent manganese ions until the solution turns bright yellow. Wash GO by centrifugation (10000rpm, 10min), first wash the GO solution with 0.01M NaOH until neutral, then wash with water to wash off excess SO4 2- , tested with saturated barium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com