Light metal doping lithium manganate positive electrode material of lithium ion battery and preparation method of positive electrode material

A technology for battery lithium manganate and positive electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of uneven mixing, large particles, and high production costs, and achieve high specific capacity, high crystallinity, and uniform particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A kind of preparation method of lithium manganese oxide cathode material of lithium ion battery, adopts following process steps:

[0023] (1) manganese dioxide and lithium carbonate are 2: 1 in molar ratio, after mixing, add 1% ethanol, grind;

[0024] (2) heating the mixture obtained in step (1) at 150-500° C. for 12 hours, then cooling naturally to obtain a dry precursor, which is uniformly ground;

[0025] (3) Mix the dried precursor with Al(NO3)3, and calcining, the calcining temperature is 700°C, the calcining time is 20 hours, after calcining, it is naturally cooled to room temperature and then ground again on a ball mill for 0.5 hours to obtain the Power lithium ion battery lithium manganese oxide cathode material Li 1.03 Al x mn 1.97-x o 4 (x=0.025, 0.05, 0.10).

Embodiment 2

[0026] Embodiment two: a kind of preparation method of lithium manganate positive electrode material of lithium ion battery, adopt following process step:

[0027] (1) Manganese acetate and lithium acetate are mixed in a molar ratio of 2: 1, mixed evenly, then added with 1% ethanol, and ground;

[0028] (2) heating the mixture obtained in step (1) at 100-400° C. for 12 hours, then cooling naturally to obtain a dry precursor, which is evenly ground;

[0029] (3) Mix the dried precursor with Al(NO3)3, and calcining, the calcining temperature is 650°C, and the calcining time is 25 hours. After calcining, it is naturally cooled to room temperature and ground again on a ball mill for 1.5 hours to obtain the Power lithium ion battery lithium manganese oxide cathode material Li 1.03 Al x mn 1.97-x o 4 (x=0.025, 0.05, 0.10);

Embodiment 3

[0030] Embodiment three: a kind of preparation method of lithium manganese oxide cathode material of lithium ion battery, adopt following process step:

[0031] (1) Mix manganese carbonate and lithium acetate in a molar ratio of 2:1, mix well and add 1% ethanol, and grind;

[0032] (2) heating the mixture obtained in step (1) at 100-400° C. for 12 hours, then cooling naturally to obtain a dry precursor, which is uniformly ground;

[0033] (3) Mix the dried precursor with CaO, and calcining, the calcining temperature is 750°C, and the calcining time is 20 hours, after calcining, it is naturally cooled to room temperature, and then ground again on a ball mill for 0.5 hours to obtain the power lithium-ion battery LiMn2O4 lithium manganate cathode material;

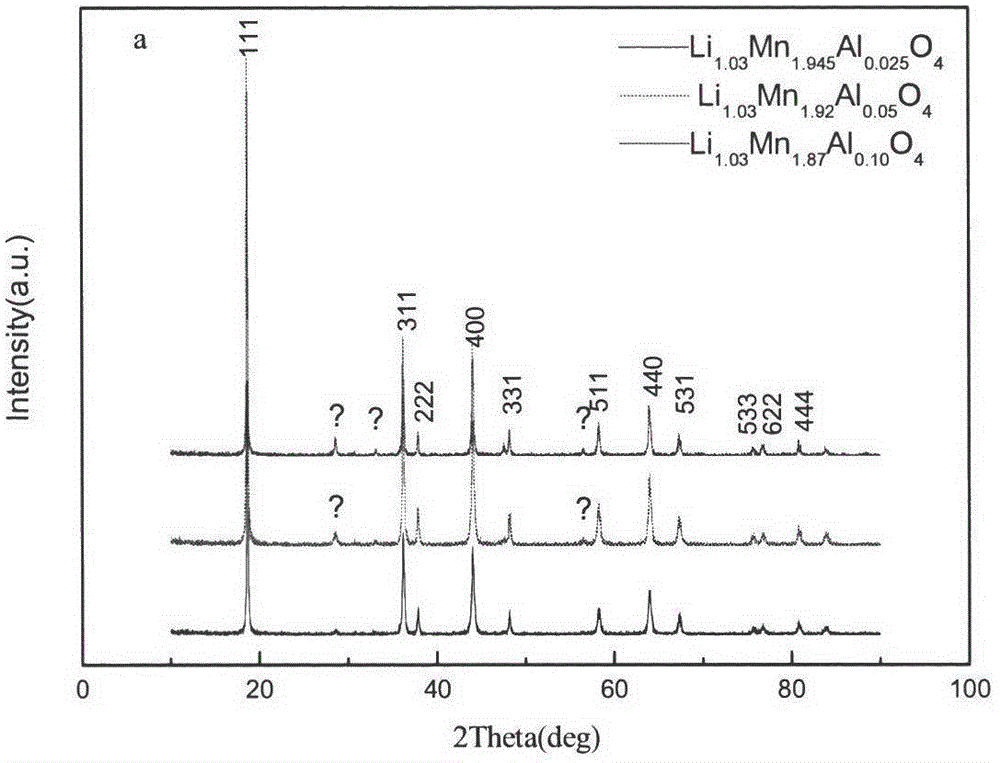

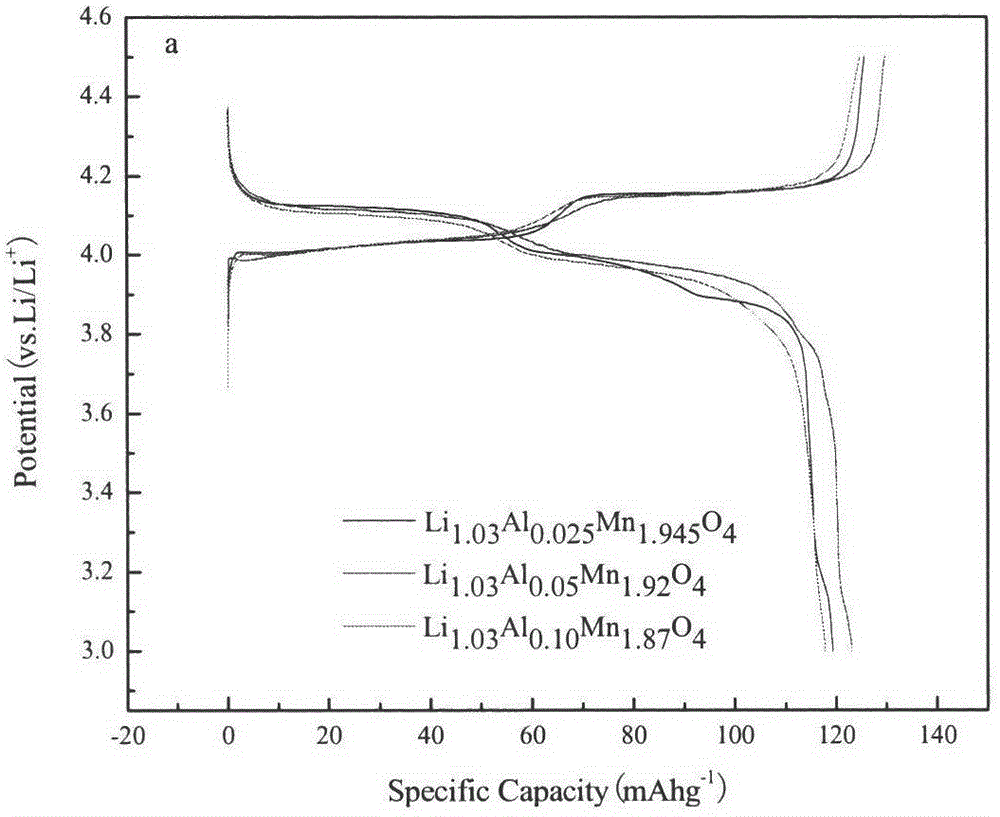

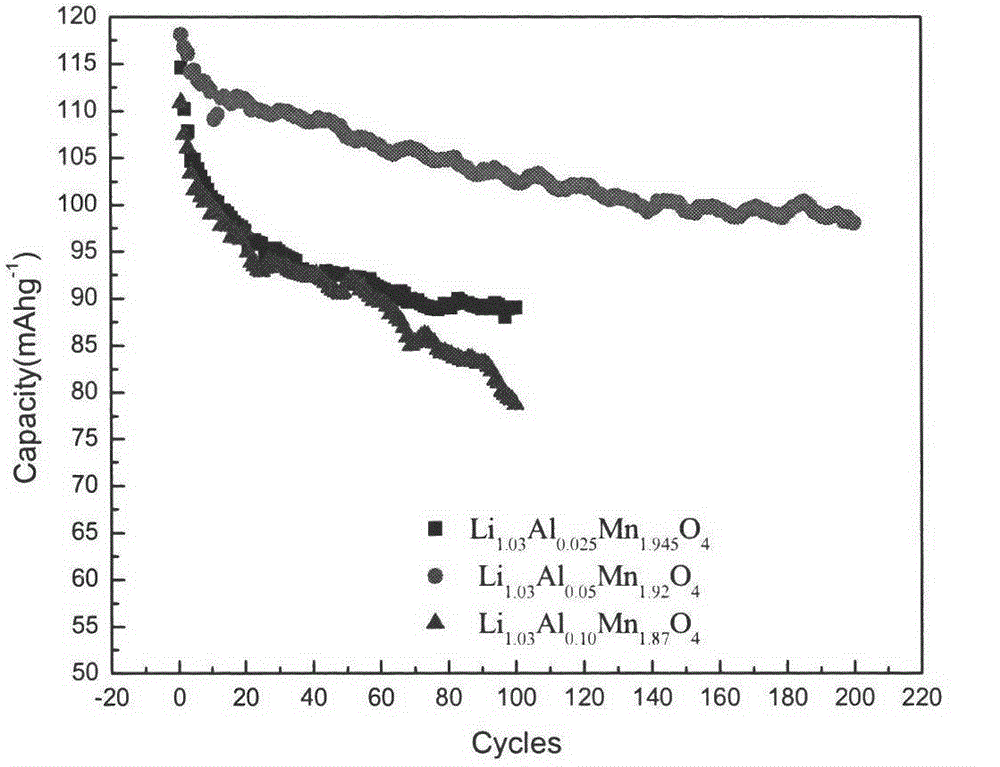

[0034] The positive electrode material that embodiment one obtains is carried out XRD detection, the result is as follows figure 1 as shown, figure 1 The abscissa is the scanning range 2θ (10-90°), and the ordinate is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com