Doped porous carbon spheres used for negative electrode material of sodium ion battery and preparation method for doped porous carbon spheres

A sodium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of no element-doped modified porous carbon sphere research reports, difficult industrial application, complex preparation process, etc. Achieve the effects of easy industrial scale application, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 1.36g of sucrose and 0.4g of concentrated sulfuric acid in 20ml of a mixed solvent consisting of water and ethylene glycol (volume ratio 6:4). Then, put the solution in a 35ml microwave tube and put it into a microwave reaction synthesizer, set the maximum power to 100W, and react at 160°C for 10 minutes to obtain precursor carbon spheres. Put the precursor carbon spheres into a tube furnace, heat-treat at 500°C for 2 hours in a nitrogen atmosphere, then heat-treat at 900°C for 30 minutes in an ammonia atmosphere, turn off the ammonia gas, replace the carbon dioxide, and treat at 900°C for 30 minutes. Nitrogen-doped porous carbon spheres were obtained.

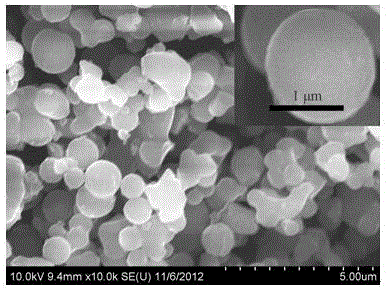

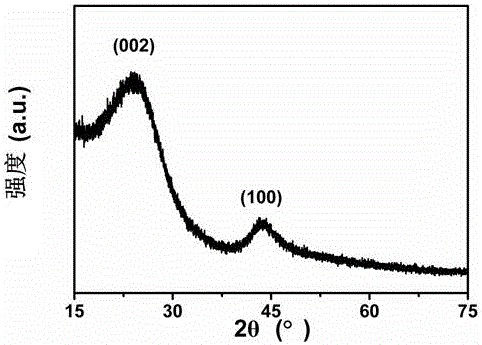

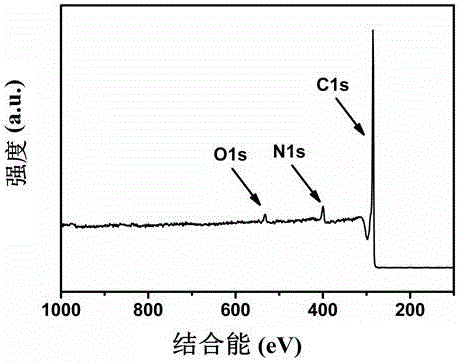

[0031] figure 1 Scanning electron micrographs of the as-prepared nitrogen-doped porous carbon spheres. from figure 1 It can be seen that the prepared nitrogen-doped porous carbon spheres are spherical with an average diameter of about 1 μm. figure 2 The X-ray diffraction pattern of nitrogen-doped porous ca...

Embodiment 2

[0035]Dissolve 0.68g of sucrose and 0.4g of concentrated sulfuric acid in 20ml of a mixed solvent consisting of water and ethylene glycol (volume ratio 6:4). Then, put the solution in a 35ml microwave tube and put it into a microwave reaction synthesizer, set the maximum power to 100W, and react at 160°C for 10 minutes to obtain precursor carbon spheres. Precursor carbon spheres and ammonium fluoride with a mass ratio of 1:1 are fully mixed and placed in a tube furnace. First, heat treatment at 600°C for 2 hours in a nitrogen atmosphere, and then 30 minutes in a carbon dioxide atmosphere to obtain fluorine-nitrogen co-doping porous carbon spheres. The method described in Example 1 was used to test the electrochemical performance of the fluorine and nitrogen co-doped porous carbon spheres as negative electrode materials for sodium ion batteries. The relevant properties and electrochemical performance of the fluorine and nitrogen co-doped porous carbon spheres are shown in Tabl...

Embodiment 3

[0037] Dissolve 3.6g of glucose and 1g of boric acid in 40ml of water, put them into a 100ml hydrothermal reactor, and react at 160°C for 3.5h to obtain precursor carbon spheres. The precursor carbon spheres and zinc chloride were mixed at a mass ratio of 1:1, put into a tube furnace, and heat-treated at 1600 °C for 1 hour under an argon atmosphere to obtain boron-doped porous carbon spheres. Its scanning electron microscope pictures are as Image 6 As shown, it can be seen that the obtained doped porous carbon spheres have an average diameter of about 200 nm. The method described in Example 1 was used to test the electrochemical performance of the doped porous carbon spheres as negative electrode materials for sodium ion batteries. The relevant properties and electrochemical performance of the boron-doped porous carbon spheres are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com