Quick waste gas desulphurization agent and preparation method thereof

A waste gas desulfurization and rapid technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of low desulfurization agent efficiency and achieve fast desulfurization speed and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

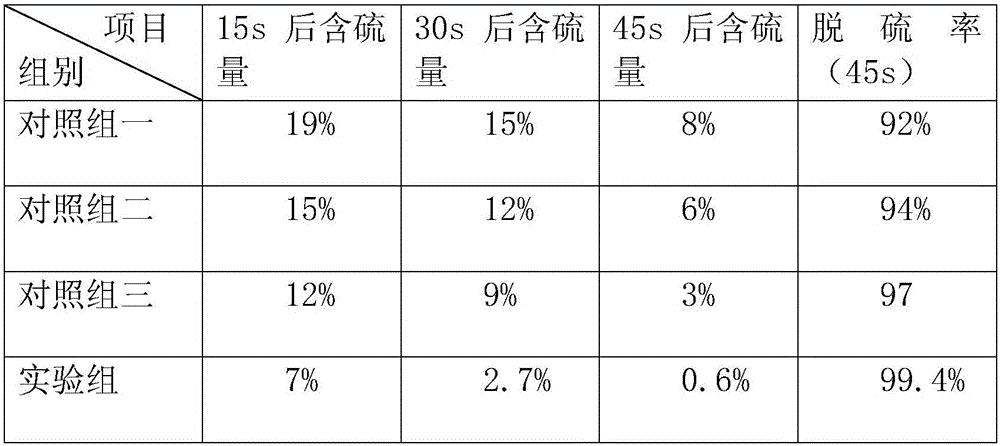

Examples

Embodiment 1

[0023] A method for preparing a rapid exhaust gas desulfurizer, comprising the following raw materials in parts by weight: 27 parts of cobalt chloride, 18 parts of sodium carbonate, 15 parts of dicobalt octacarbonyl, 6 parts of basic nickel carbonate, and 20 parts of basic aluminum sulfate 20 parts of potassium hydroxide, 6 parts of activated carbon, 4 parts of calcium lactate, 12 parts of iron oxide, 6 parts of manganese oxide, 6 parts of zirconium dioxide, 2 parts of sodium zirconate, 6 parts of praseodymium and neodymium oxide, 18 parts of lanthanum oxide, 26 parts of acetic acid, 5 parts of sodium hydroxide and 4 parts of magnesium perchlorate.

[0024] A preparation method of fast exhaust gas desulfurizer comprises the following steps:

[0025] 1) Mix 15 parts of dicobalt octacarbonyl, 6 parts of basic nickel carbonate, 20 parts of basic aluminum sulfate, 20 parts of potassium hydroxide, 6 parts of activated carbon, 4 parts of calcium lactate, 12 parts of iron oxide, 6 pa...

Embodiment 2

[0035] A rapid exhaust gas desulfurizer and a preparation method thereof, comprising the following raw materials in proportions by weight: 25 parts of cobalt chloride, 20 parts of sodium carbonate, 17 parts of dicobalt octacarbonyl, 8 parts of basic nickel carbonate, basic aluminum sulfate 22 parts, potassium hydroxide 22 parts, activated carbon 8 parts, calcium lactate 6 parts, iron oxide 14 parts, manganese oxide 8 parts, zirconium dioxide 8 parts, sodium zirconate 4 parts, praseodymium neodymium oxide 8 parts, lanthanum oxide 20 parts , 28 parts of acetic acid, 7 parts of sodium hydroxide and 6 parts of magnesium perchlorate.

[0036] A preparation method of fast exhaust gas desulfurizer, comprising the following steps:

[0037] 1) 17 parts of dicobalt octacarbonyl, 8 parts of basic nickel carbonate, 22 parts of basic aluminum sulfate, 22 parts of potassium hydroxide, 8 parts of activated carbon, 6 parts of calcium lactate, 14 parts of iron oxide, 8 parts of manganese oxide...

Embodiment 3

[0047] A rapid exhaust gas desulfurizer and a preparation method thereof, comprising the following raw materials in proportions by weight: 26 parts of cobalt chloride, 19 parts of sodium carbonate, 16 parts of dicobalt octacarbonyl, 7 parts of basic nickel carbonate, basic aluminum sulfate 21 parts, potassium hydroxide 21 parts, activated carbon 7 parts, calcium lactate 5 parts, iron oxide 13 parts, manganese oxide 7 parts, zirconium dioxide 7 parts, sodium zirconate 3 parts, praseodymium neodymium oxide 7 parts, lanthanum oxide 19 parts , 27 parts of acetic acid, 6 parts of sodium hydroxide and 5 parts of magnesium perchlorate.

[0048] A preparation method of fast exhaust gas desulfurizer, comprising the following steps:

[0049] 1) 16 parts of dicobalt octacarbonyl, 7 parts of basic nickel carbonate, 21 parts of basic aluminum sulfate, 21 parts of potassium hydroxide, 7 parts of activated carbon, 5 parts of calcium lactate, 13 parts of iron oxide, 7 parts of manganese oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com