Water dispersible granule and anhydrous preparation technology thereof

A technology of dispersible particles and dispersants, which is applied in the direction of biocides, biocides, animal repellents, etc., can solve the problems of endangering human health, environmental pollution, and high cost of use, and achieve small environmental pollution, reduce environmental pollution, and save energy. The effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

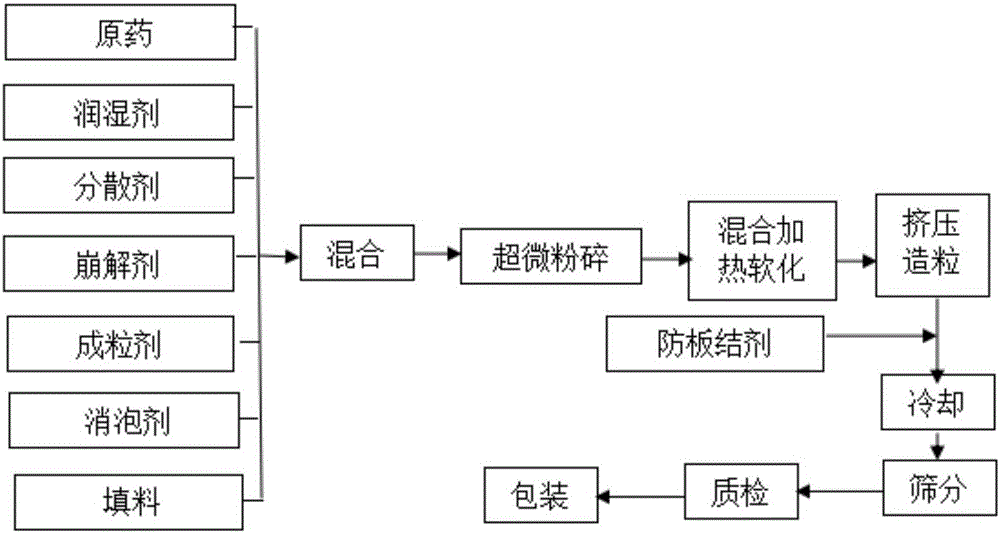

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: 80% cyromazine water-dispersible granules

[0035] Weigh 81% of cyromazine powder, wetting agent sodium lauryl sulfate 2%, dispersant 8906 naphthalene sulfonate 3%, sodium lignosulfonate 2%, disintegrant sodium sulfate 3%, granulate Glucose 5%, anti-foaming agent isooctyl alcohol 0.1%, anti-caking agent 0.1%, carrier kaolin supplemented to 100%; cyromazine and other additives except anti-caking agent were placed in a gravity-free mixer according to the formula ratio Mix in medium for 20 minutes, then put the mixture into the twin-screw mixer (I), and pulverize it through the airflow mill while mixing to reach a particle size of more than 1000 mesh, collect it through a cyclone separator and a bag filter, and finally mix it in a double-helix mixer. Mix again in machine (II) for 30 minutes to obtain uniform mother powder. Accurately weigh a certain amount of parent powder, heat and soften in a cyclone, pour the material into an extrusion granulator to granu...

Embodiment 2

[0036] Embodiment 2: 40% acetamiprid water-dispersible granules

[0037] Weigh 40.5% of acetamiprid raw powder, 5% of wetting agent octylsulfosuccinate sodium salt, 7% of dispersant naphthalenesulfonate formaldehyde condensate, 3% of lignosulfonate calcium salt, and 10% of disintegrating agent sodium sulfate %, granulating agent fructose 10%, defoamer isooctyl alcohol 0.2%, anti-caking agent 0.3%, carrier kaolin is supplemented to 100%; acetamiprid and other additives except anti-caking agent are added to no Mix in a gravity mixer for 20 minutes, then put the mixture into a double-screw mixer (I), and pulverize it through an airflow mill while mixing to reach a particle size of more than 1000 mesh, collect it through a cyclone separator and a bag filter, and finally Mix again for 30 minutes in the twin-screw mixer (II) to obtain a uniform mother powder. Accurately weigh a certain amount of parent powder, heat and soften in a cyclone, pour the material into an extrusion granul...

Embodiment 3

[0038] Embodiment 3: 37% difenoconazole water dispersible granule

[0039] Weigh 37.2% of the original powder of difenoconazole, 4% of sodium lauryl sulfate as a wetting agent, 3% of naphthalenesulfonate formaldehyde condensate as a dispersant, 4% of sodium lignosulfonate, and 20% of urea as a disintegrating agent , granulating agent glucose 13%, defoaming agent organic silicone 0.3%, anti-caking agent 0.3%, carrier diatomaceous earth to 100%, difenoconazole and other additives except anti-caking agent according to the formula The ratio is mixed in a gravity-free mixer for 20 minutes, and then the mixture is put into a double-screw mixer (I). While mixing, it is pulverized by a jet mill to reach a particle size of more than 1000 mesh, and is collected by a cyclone separator and a bag filter. , and finally mixed again in the twin-screw mixer (II) for 30 minutes to obtain a uniform mother powder. Accurately weigh a certain amount of parent powder, heat and soften in a cyclone, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com