Nickel selenide/graphene/carbon nanotube composite material and preparation method thereof

A technology of acidifying carbon nanotubes and carbon nanotubes, which is applied in the direction of hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of affecting catalytic performance and electrochemical active sites cannot be fully exposed, and achieve easy operation and effective Quick preparation method, ingenious effect of experimental design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 、 This embodiment includes the following steps:

[0036] (1) Ultrasonic dispersion of graphite oxide and acidified carbon nanotubes in water to obtain a concentration of 8 mg mL -1 and 4 mg mL -1 For the dispersion liquid, mix its water dispersion liquid at a volume ratio of 1:1, and stir to make it evenly mixed;

[0037] (2) Quenching the obtained graphene oxide / acidified carbon nanotube mixed dispersion with liquid nitrogen and freeze-drying to obtain graphene oxide / acidified carbon nanotube aerogel;

[0038] (3) The graphene oxide / acidified carbon nanotube airgel was carbonized at high temperature in high-purity nitrogen, the high-temperature carbonization temperature was 800°C, and the high-temperature carbonization time was 2 h, and the graphene / carbon nanotube airgel was prepared;

[0039] (4) Dissolve 1 mmol of nickel nitrate hexahydrate and 3 mmol of urea in a mixture of 30 mL of ethanol and water (volume ratio 2:1), and stir for a period of time t...

Embodiment 2

[0042] Example 2 、 Change the selenization temperature in Example 1 to 450°C, the rest are the same as in Example 1, and the composite material finally obtained is denoted as NiSe 2 -GCA-2.

Embodiment 3

[0043] Example 3 、 Change the selenization temperature in Example 1 to 550°C, and the rest are the same as in Example 1, and the finally obtained composite material is denoted as NiSe 2 -GCA-3.

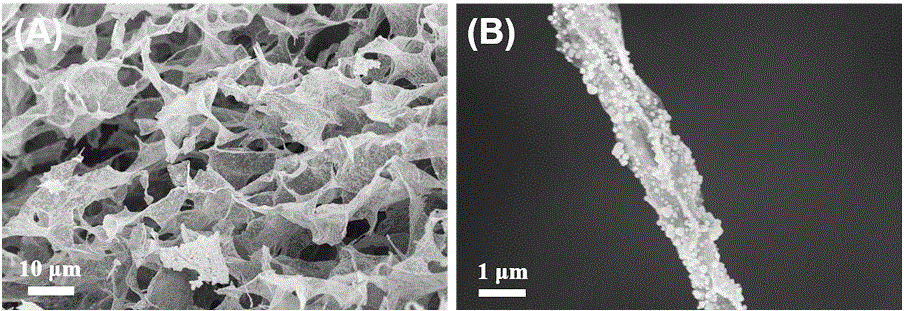

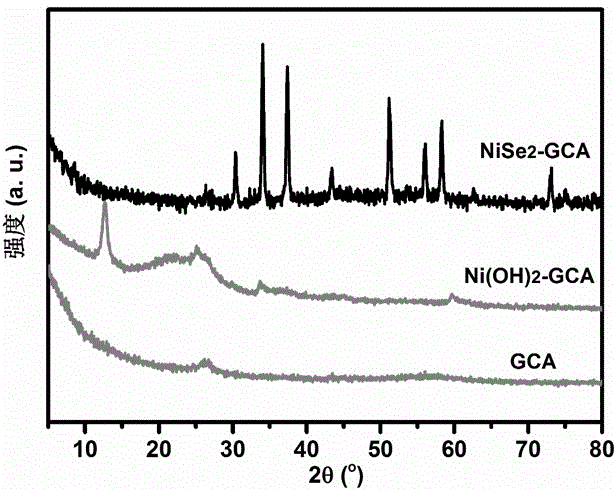

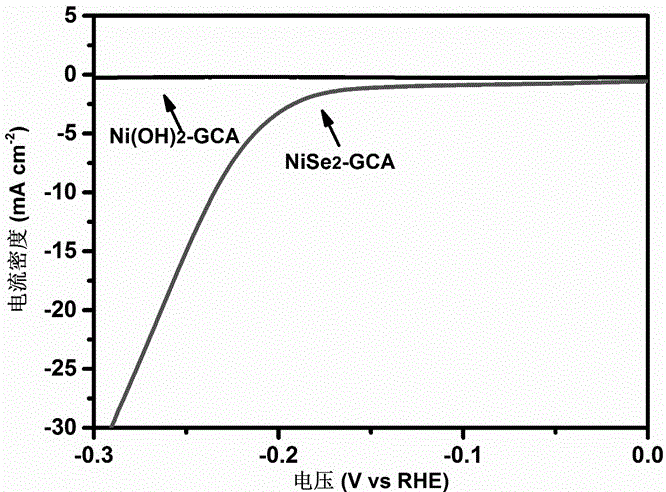

[0044] figure 1 It is the SEM image of the nickel selenide / graphene / carbon nanotube composite material of Example 2, (A) low magnification, (B) high magnification. figure 2 It is the XRD figure of the nickel selenide / graphene / carbon nanotube composite material of the embodiment 2 of the present invention. image 3 It is the linear sweep voltammetry curve (LSV) of nickel selenide / graphene / carbon nanotube composite material and nickel hydroxide / graphene / carbon nanotube composite material in Example 2 of the present invention. The nickel selenide / graphene / carbon nanotube composites prepared in Example 1 and Example 3 have similar morphology and properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com