Polymer metal complex catalyst for synthesizing methyl isobutyl ketone

A technology of methyl isobutyl ketone and metal complexation, applied in the field of catalysis, can solve the problems of easy corrosion of equipment, many by-products, and low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

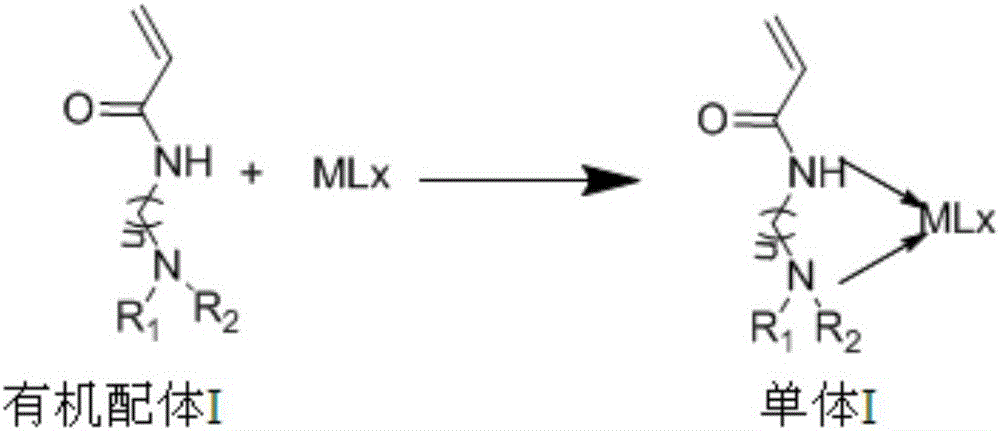

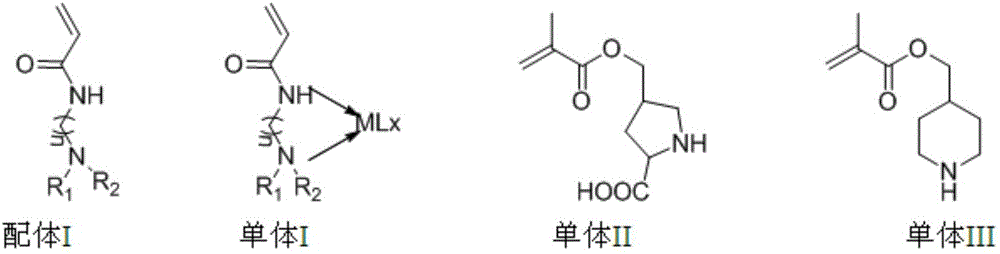

[0046] (1) Preparation of metal complex monomer

[0047] 0.17g ruthenium chloride trihydrate (containing ruthenium 37.0wt%), 0.09g ferric chloride (containing iron 34.5wt%), 5g deionized water and 14.17g organic ligand I (n is 2, R 1 , R 2 Both are methyl) mixed, under the protection of nitrogen, slowly add the mixed liquid dropwise to 200mL n-hexane in a reflux state at a temperature of 69°C. The paraffin oil layer was cooled to 0-5°C and left to stand for 12 hours. The precipitated solid was filtered and dried in vacuum (-0.095MPa) at 30°C for 24 hours to obtain 11.63g of a mixture of ligand I and monomer I with a yield of 80.8%.

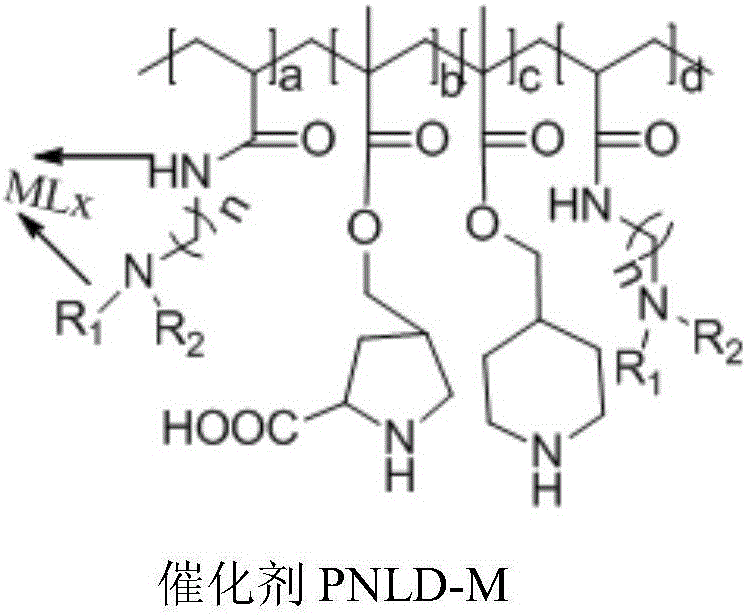

[0048] (2) Preparation of polymer catalyst

[0049] Add 6.32g of the mixture of ligand I and monomer I prepared in the previous step, 0.80g of monomer II, 0.12g of monomer III, and 0.09g of the initiator benzoyl peroxide (BPO) into the 100mL reaction eggplant bottle with branch pipe in sequence and 15mL N,N-dimethylformamide (DMF), stirred to d...

Embodiment 2

[0051] (1) Preparation of metal complex monomer

[0052] With 0.83g hexahydrate chloroplatinic acid (containing platinum 37.5wt%), 0.45g ferric chloride (containing iron 34.5wt%), 0.06g hexahydrate nickel chloride (containing nickel 24.5wt%), 0.03g cupric chloride ( Copper 47.2wt%), 5g deionized water and 14.17g organic ligand I (n is 2, R 1 , R 2 Both are methyl) mixed, under the protection of nitrogen, slowly add the mixed solution to 111 ° C, 200mL of toluene in the reflux state, after the dropwise addition, keep the reaction for 24 hours, separate layers while hot, the obtained toluene oil layer, Cool down to 0-5°C, let stand for 12 hours, filter the precipitated solid, and dry under vacuum (-0.095MPa) at 30°C for 24 hours to obtain 13.04g of a mixture of ligand I and monomer I, with a yield of 85.0%.

[0053] (2) Preparation of polymer catalyst

[0054] Add 2.06g of the mixture of ligand I and monomer I prepared in the previous step, 0.80g of monomer II, 0.23g of monom...

Embodiment 3

[0056] (1) Preparation of metal complex monomer

[0057] With 1.63g chloroplatinic acid hexahydrate (containing platinum 37.5wt%), 1.62 chromium chloride hexahydrate (containing chromium 19.1wt%), 0.06g copper chloride (containing copper 47.2wt%), 5g deionized water and 14.17g Organic ligand I (n is 2, R 1 , R 2 Both are methyl) mixed, under the protection of nitrogen, slowly add the mixture dropwise to 200mL methylene chloride under reflux at 40°C. The methyl chloride oil layer was cooled to 0-5°C and left to stand for 12 hours, and the precipitated solid was filtered and dried under vacuum (-0.095MPa) at 30°C for 24 hours to obtain 14.91g of a mixture of ligand I and monomer I, with a yield of 84.6%.

[0058] (2) Preparation of polymer catalyst

[0059] Add 3.51g of the mixture of ligand I and monomer I prepared in the previous step, 0.80g monomer II, 0.35g monomer III, 0.12g initiator azobisisobutyronitrile (AIBN ) and 15mL of methanol, stirred and dissolved, deoxygenat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com