Method for modifying titanium-dioxide lithium-ion battery negative pole material simultaneously by using carbon and monolayer molybdenum disulfide

A single-layer molybdenum disulfide and lithium-ion battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low storage capacity and poor conductivity, and achieve simple reaction, inhibition of agglomeration, and high specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

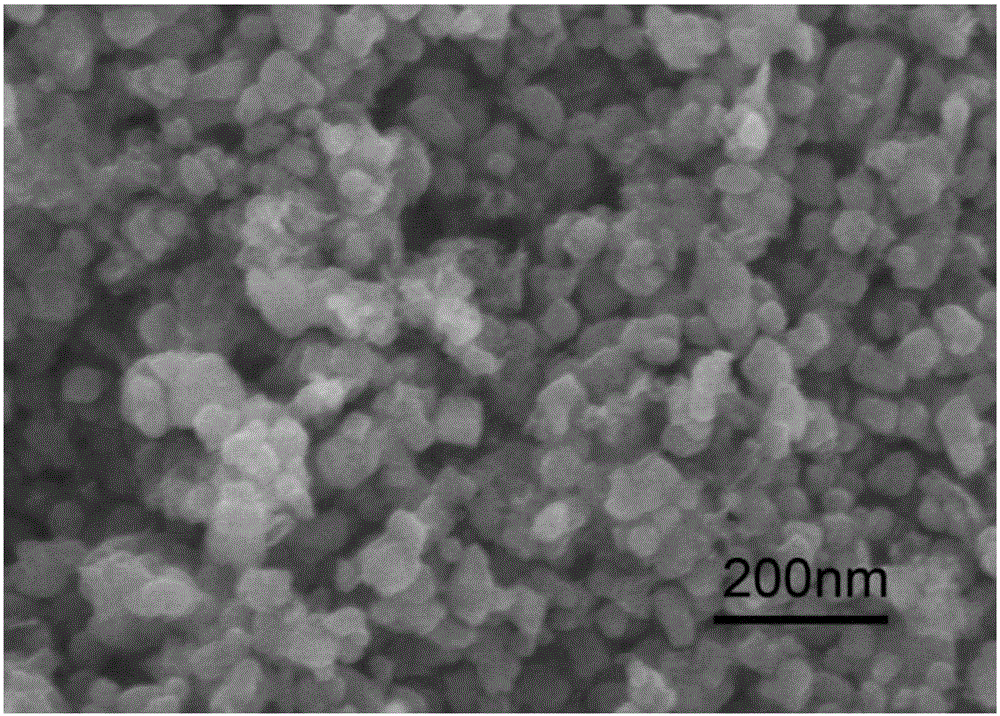

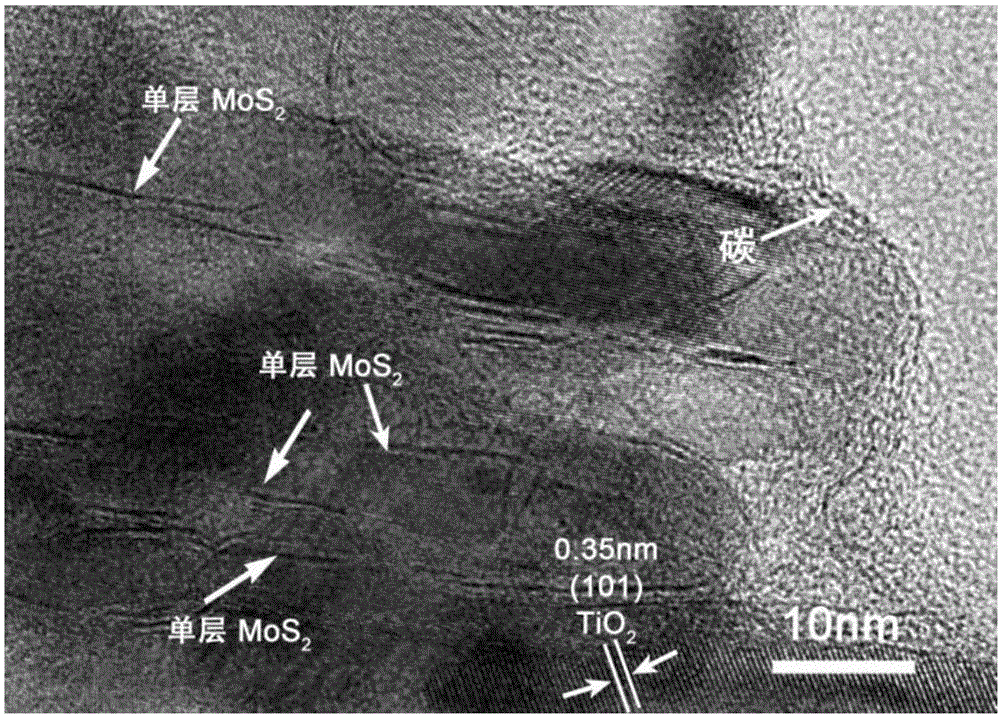

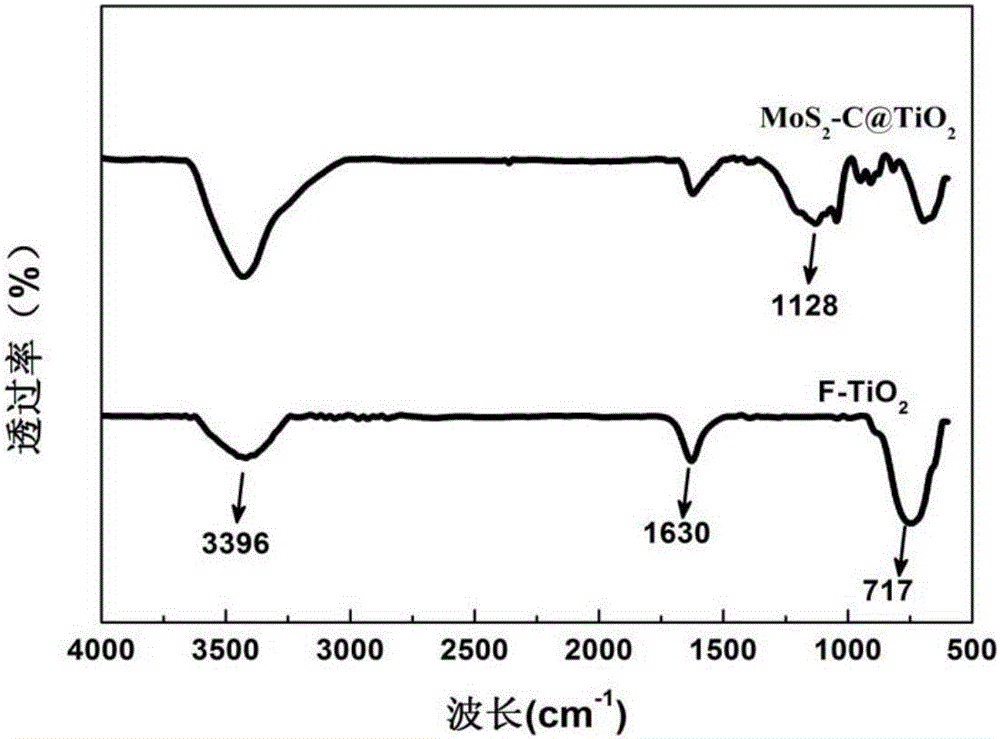

[0023] 12.5ml of butyl titanate and 1.5ml of hydrofluoric acid (40wt%) were added to a 50ml reaction kettle, and placed in a thermostat for hydrothermal heating at 200°C for 24h. After the reaction is over, it is naturally cooled to room temperature, the obtained suspension is centrifuged with alcohol and deionized water, and the bottom powder is collected and heated to dry to obtain a white powder. Weigh 200 mg of the obtained white powder, 100 mg of glucose, 20 mg of ammonium molybdate, and 22.8 mg of thiourea, and sequentially add them to 200 ml of deionized water to obtain a uniform suspension. Put the mixed suspension in a freezer, freeze and place it in a freeze dryer at -50°C for freeze drying until it is dried to obtain a mixture. Grind the obtained precursor to fine powder, spread it flat in the ark and place it in a tube furnace. Inject 200ml / min of argon inert gas for 20 minutes to remove the air in the tube furnace, and then set it at 10℃ / min The temperature is inc...

Embodiment 2

[0026] 10.5ml of butyl titanate and 1.5ml of hydrofluoric acid (40wt%) were added to a 50ml reaction kettle, and placed in a thermostat for water heating at 180°C for 22h. After the reaction is over, it is naturally cooled to room temperature, the obtained suspension is centrifuged with alcohol and deionized water, and the bottom powder is collected and heated to dry to obtain a white powder. Weigh 180 mg of the obtained white powder, 50 mg of glucose, 20 mg of ammonium molybdate, and 21 mg of thiourea, and sequentially add 200 ml of deionized water to obtain a uniform suspension. Put the mixed suspension in a freezer, freeze and place it in a freeze dryer at -50°C for freeze drying until it is dried to obtain a mixture. Grind the obtained precursor to fine powder, spread it flat in an ark and place it in a tube furnace. Inject 200ml / min of argon inert gas for 20 minutes to remove the air in the tube furnace, and then use 2℃ / min The temperature was raised to 700℃ and kept for ...

Embodiment 3

[0028] 13.5ml of butyl titanate and 1.5ml of hydrofluoric acid (40wt%) were added to a 50ml reactor, and placed in a thermostat for hydrothermal heating at 220°C for 26h. After the reaction is over, it is naturally cooled to room temperature, the obtained suspension is centrifuged with alcohol and deionized water, and the bottom powder is collected and heated to dry to obtain a white powder. Weigh 240 mg of the obtained white powder, 150 mg of glucose, 20 mg of ammonium molybdate, and 25 mg of thiourea, and sequentially add them to 200 ml of deionized water to obtain a uniform suspension. Put the mixed suspension in a freezer, freeze and place it in a freeze dryer at -50°C for freeze drying until it is dried to obtain a mixture. Grind the obtained precursor to fine powder, spread it flat in the ark and place it in a tube furnace. Inject 200ml / min of argon inert gas for 20 minutes to remove the air in the tube furnace, and then set it at 10℃ / min The temperature was raised to 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com