Preparation method for algae-culturing agent for aquaculture

A technology of using algae-cultivating agent and aquaculture, applied in the preparation and application of organic fertilizers, fertilizers made from biological wastes, etc., can solve the problems of environmental factors, single effect, and no development, etc. The effect of accelerating growth and reproduction and enhancing metabolic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The attapulgite at the particle size of Example 1 has strong cohesiveness under extrusion conditions, and the contained toxic elements such as mercury, lead, and arsenic are respectively lower than the national standards.

[0030] Take 10kg of dry chicken manure, pass through a 10-mesh sieve, mix well, and add 40mL of EM active calcium solution. The method is to dilute the EM active calcium solution, spray evenly on the mixed dry chicken manure, adjust the water content to about 40% with chlorine-free water, and carry out airtight anaerobic fermentation at 35°C for 5 days. Take 5.5kg of the above-mentioned anaerobic fermented chicken manure, 2kg of fish meal, 1.5kg of bean cake, 0.5kg of spirulina dry powder, and 0.5kg of EM solid bokashi, first crush the above raw materials respectively, pass through a 60-mesh sieve, mix well, and evenly spray 1% The EM stock solution is controlled at about 40% water content, stacked and fermented at room temperature for 25 days, and d...

Embodiment 2

[0032] Take 10kg of dry chicken manure, pass through a 20-mesh sieve, mix well, and add 50mL of EM active calcium solution. The method is to dilute the EM active calcium solution, spray evenly on the mixed dry chicken manure, adjust the water content to about 40% with chlorine-free water, and carry out airtight anaerobic fermentation at 30°C for 6 days. Take 5.0kg of the above-mentioned anaerobic fermented chicken manure, 2.5kg of fish meal, 1.5kg of bean cake, 0.5kg of spirulina dry powder, and 0.5kg of EM solid bokashi. %EM stock solution, so that the water content is controlled at about 40%, stacked and fermented at room temperature for 23 days, and dried until the mass water content is less than or equal to 30%. Then add 200 grams of attapulgite clay through a 200-mesh sieve to the above-mentioned fermentation material, mix evenly, granulate with a granulator, the particle diameter is 5.0mm, and dry at 50°C, with a mass water content of about 12%.

Embodiment 3

[0034] Take 10kg of dry chicken manure, pass through a 10-mesh sieve, mix well, and add 30mL EM active calcium solution. The method is to dilute the EM active calcium solution, spray evenly on the mixed dry chicken manure, adjust the water content to about 40% with chlorine-free water, and carry out airtight anaerobic fermentation at 25°C for 5 days. Take 5.0kg of the above-mentioned anaerobic fermented chicken manure, 2.0kg of fish meal, 2.0kg of bean cake, 0.5kg of dry spirulina powder, and 0.5kg of EM solid bokashi. %EM stock solution, so that the water content is controlled at about 40%, stacked and fermented at room temperature for 24 days, and dried until the mass water content is less than or equal to 30%. Then add 200 grams of attapulgite clay through a 200-mesh sieve to the above-mentioned fermentation material, mix evenly, granulate with a granulator, the particle diameter is 5.0mm, and dry at 50°C, with a mass water content of about 12%.

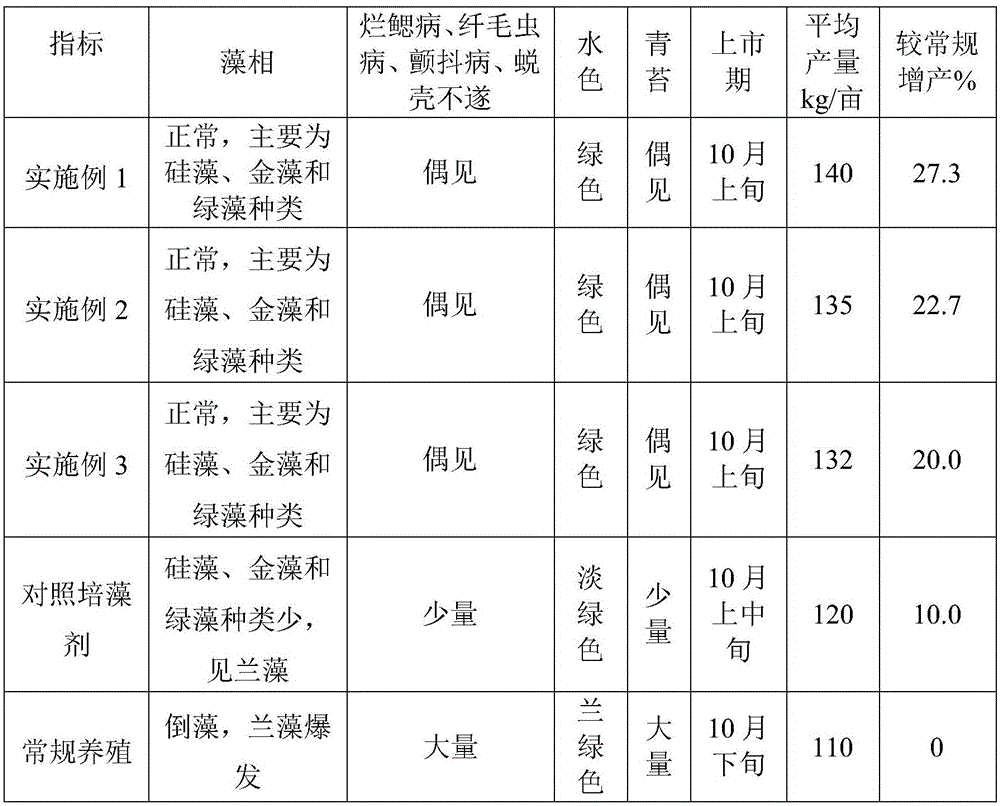

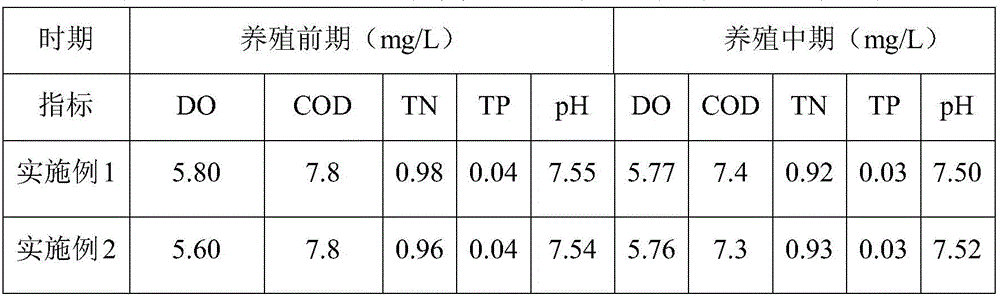

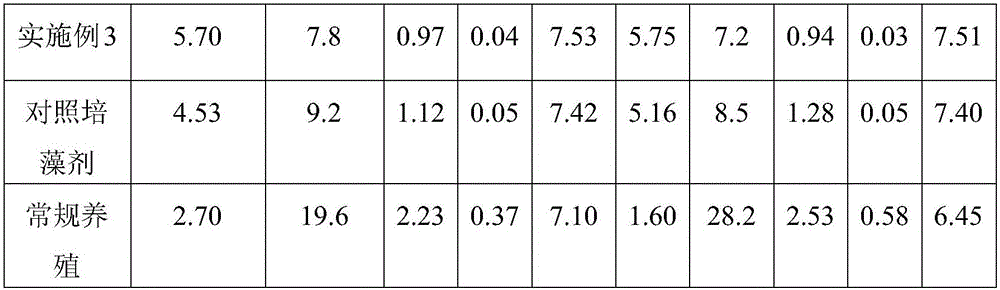

[0035] The algae cultivatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com