A kind of preparation method of thermal spraying ceramic coating with high anti-wear and low friction coefficient

A low friction coefficient, ceramic coating technology, applied in the coating, metal material coating process, fusion spraying and other directions, can solve the problems of the ceramic coating tribological properties can not be greatly improved, the effect is not very obvious, etc. Achieve the effect of low friction coefficient and wear rate, excellent friction characteristics, and improved wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

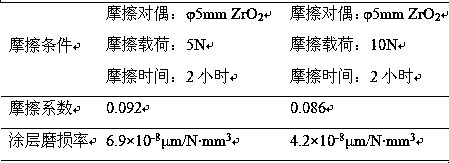

Embodiment 1

[0022] A: The surface of the 1Cr18Ni9Ti stainless steel substrate is roughened and cleaned, and then placed on the spraying table. Using atmospheric plasma spraying equipment, the NiAl transitional coating and Al are sprayed on the stainless steel substrate. 2 o 3 Ceramic coating, Al 2 o 3 The thickness of the ceramic coating is about 270 μm; then the surface of the ceramic coating is ground and polished, and the surface roughness Ra≈1.6 μm.

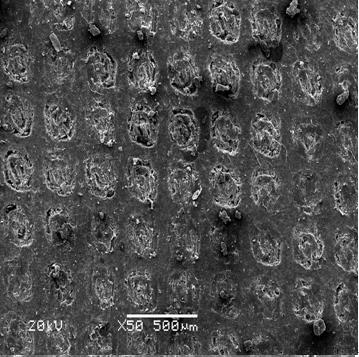

[0023] B: the Al prepared in step A 2 o 3 The ceramic coating is placed on a laser texturing table to prepare surface micropores. The prepared micropores have a diameter of about 230 μm to 280 μm and a pore depth of about 50 μm to 70 μm. 32%, and the spacing between the holes is basically the same.

[0024] C: the Al prepared in step B 2 o 3 The ceramic coating was vacuum impregnated (vacuum: -0.72 bar) for 4 hours after soaking in a PTFE emulsion with a solid content of 60%.

[0025] D: Take out the coating completed in step C f...

Embodiment 2

[0031] A: The surface of the 7075 aluminum alloy substrate is roughened and cleaned, then placed on the spraying table, and the NiAl transition coating and Al are sprayed on the aluminum alloy substrate by using atmospheric plasma spraying equipment. 2 o 3 Ceramic coating, Al 2 o 3 The thickness of the ceramic coating is about 180 μm; then the surface of the ceramic coating is ground and polished, and the surface roughness Ra≈1.4 μm.

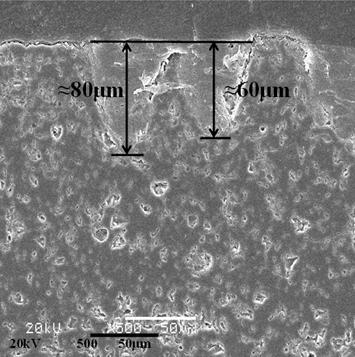

[0032] B: the Al prepared in step A 2 o 3 The ceramic coating is placed on a laser texturing table to prepare surface micropores. The prepared micropores have a diameter of about 240 μm to 260 μm and a pore depth of about 60 μm to 80 μm. 35%, and the spacing between the holes is basically the same.

[0033] C: the Al prepared in step B 2 o 3 The ceramic coating was vacuum impregnated (vacuum: -0.74 bar) for 6 hours after soaking in PTFE emulsion with 50% solids content.

[0034]D: Take the coating completed in step C out of the PTFE emul...

Embodiment 3

[0040] A: The surface of the GH 4169 substrate is roughened and cleaned and placed on the spraying table, and the NiAl transitional coating and Al are sprayed on the GH 4169 substrate by using atmospheric plasma spraying equipment. 2 o 3 Ceramic coating, Al 2 o 3 The thickness of the ceramic coating is about 300 μm; then the surface of the ceramic coating is ground and polished, and its surface roughness is Ra≈0.8 μm.

[0041] B: the Al prepared in step A 2 o 3 The ceramic coating is placed on a laser texturing table to prepare surface micropores. The prepared micropores have a diameter of about 220 μm to 270 μm and a pore depth of about 55 μm to 74 μm. 40%, and the spacing between the holes is basically the same.

[0042] C: the Al prepared in step B 2 o 3 The ceramic coating was vacuum impregnated (vacuum: -0.79 bar) for 5 hours after soaking in PTFE emulsion with a solid content of 55%.

[0043] D: Take the coating completed in step C out of the PTFE emulsion, put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com