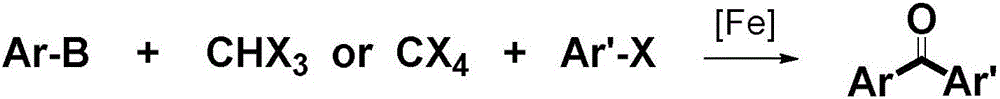

Method for carbonylation synthesis of diaryl ketones through iron catalysis

A technology for the synthesis of diaryl ketones, which is applied in the field of catalytic synthesis, can solve the problems of carbonyl sources being toxic, difficult to handle, and flammable, and achieve the effects of low toxicity, easy handling, and safe handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

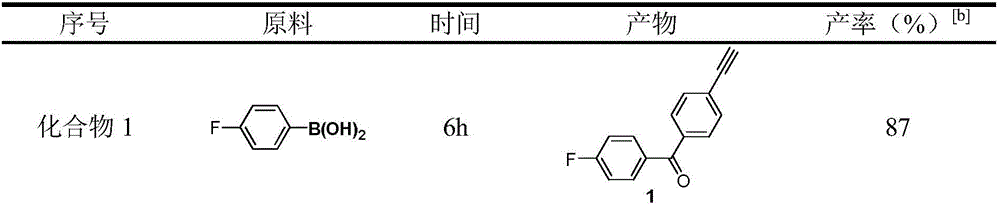

Embodiment 1

[0038] Compound 1: Add ferrous chloride (0.05mmol), 4-iodophenylacetylene (0.5mmol), 4-fluorophenylboronic acid (0.75mmol), sodium carbonate (1.0mmol) and cesium hydroxide monohydrate to a 25mL reaction flask in sequence (2.5mmol), sodium iodide (0.25mmol), pivalic acid (0.75mmol), chloroform (1.5mmol) and polyethylene glycol-400 (2.0g), and react at 120°C for 6h. Cool to room temperature, extract, evaporate the solvent under reduced pressure, and separate by column chromatography to obtain a yield of 87%.

Embodiment 2

[0040] Compound 2: Add ferrous chloride (0.05mmol), 4-cyclopropyl iodobenzene (0.5mmol), 2-methylphenylboronic acid (0.75mmol), sodium tert-butoxide (1.0mmol) to a 25mL reaction flask in sequence, Sodium carbonate (1.0 mmol), cesium hydroxide monohydrate (2.5 mmol), sodium iodide (0.25 mmol), pivalic acid (0.75 mmol), chloroform (1.5 mmol) and polyethylene glycol-1000 (2.0 g), And react at 120°C for 16h. Cool to room temperature, extract, evaporate the solvent under reduced pressure, and separate by column chromatography to obtain a yield of 79%.

Embodiment 3

[0042] Compound 3: Add ferrous chloride (0.05mmol), 4-nitroiodobenzene (0.5mmol), 2-cyclohexylphenylboronic acid (0.75mmol), sodium carbonate (1.0mmol) and hydrogen monohydrate to a 25mL reaction flask in sequence Cesium oxide (2.5mmol), sodium iodide (0.25mmol), pivalic acid (0.75mmol), fluoroform (1.5mmol) and polyethylene glycol-400 (2.0g) were reacted at 120°C for 15h. Cool to room temperature, extract, evaporate the solvent under reduced pressure, and separate by column chromatography to obtain a yield of 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com