Preparation method of anode film linear ion source assisted cBN (cubic boron nitride) coated cutting tool

A linear ion source, cubic boron nitride technology, applied in coating, ion implantation plating, superimposed layer plating and other directions, can solve the problem of low nitrogen ionization rate, small residual application, high residual stress film adhesion Weak problems, to achieve the effect of improving mechanical properties, changing ionization rate, and improving bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

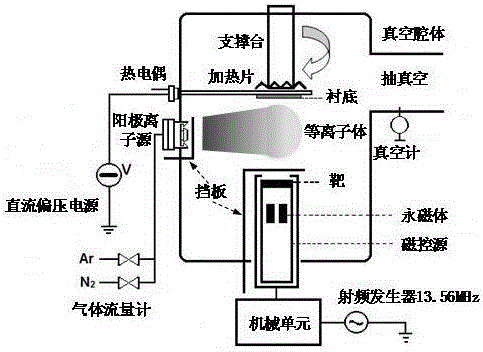

[0029] A method for preparing an anode film linear ion source assisted cubic boron nitride coated tool, the steps are as follows:

[0030] (1) Substrate pretreatment: Use YG6 cemented carbide blades as the substrate material, firstly grind the surface of the YG6 cemented carbide blades, and use W7, W14, W20 type diamond sandpaper to grind for a total of 30 minutes from coarse to fine. After that, put the blade in hydrofluoric acid solution for ultrasonic cleaning for 10 minutes, and then place the substrate in an acetone suspension composed of diamond microcrystalline powder with a particle size of 0.5-1 μm for ultrasonic cleaning for 20 minutes. Ultrasonic cleaning with deionized water for 10 minutes, after taking it out, filter the surface with deionized water immediately, put it in absolute ethanol solution and ultrasonically clean it for 10 minutes, and finally clean it with N 2 Dry and set aside to obtain the treated substrate. Use chemical vapor deposition to deposit na...

Embodiment 2

[0034] A method for preparing an anode film linear ion source assisted cubic boron nitride coated tool, the steps are as follows:

[0035] (1) Substrate pretreatment: Use high-speed steel blades as the substrate material, firstly grind the surface of the high-speed steel blades, and use W7, W14, and W20 diamond sandpaper to grind for a total of 25 minutes in sequence from coarse to fine. After that, put the blade in hydrofluoric acid solution for ultrasonic cleaning for 15 minutes, and then place the substrate in an acetone suspension composed of diamond microcrystalline powder with a particle size of 0.5-1 μm for ultrasonic cleaning for 15 minutes. Ultrasonic cleaning with deionized water for 10 minutes, after taking it out, filter the surface with deionized water immediately, put it in absolute ethanol solution and ultrasonically clean it for 10 minutes, and finally clean it with N 2 Dry and set aside to obtain the treated substrate. Nano-aluminum nitride is deposited on th...

Embodiment 3

[0039] The difference between this embodiment and Embodiments 1 and 2 is that the nano-transition layer is not deposited after the tool substrate is polished and cleaned, but is directly placed in the magnetron sputtering device to open the linear ion source of the anode film and adopt the cleaning mode (high voltage , low current, low duty ratio) pre-sputtering treatment is performed on the tool base material, and after the pre-sputtering treatment, the same vertical boron nitride deposition as in Embodiments 1 and 2 is carried out. This embodiment omits the deposition process of the nano-transition layer, which is beneficial to improve the deposition cycle of some tool substrates with better bonding force with cubic boron nitride, and reduce the production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com