Method for detecting content of trace impurity content in metal by glow-discharge mass spectrometry

A technology of glow discharge mass spectrometry and trace impurities, which is used in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of low sensitivity and resolution, and achieve a wide range of analysis, low detection limit, and less interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

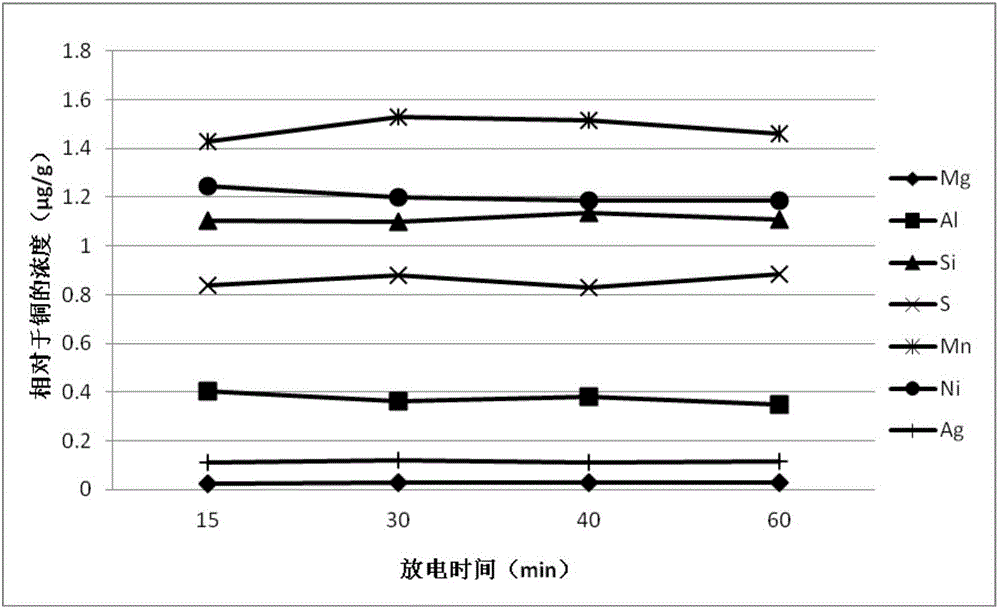

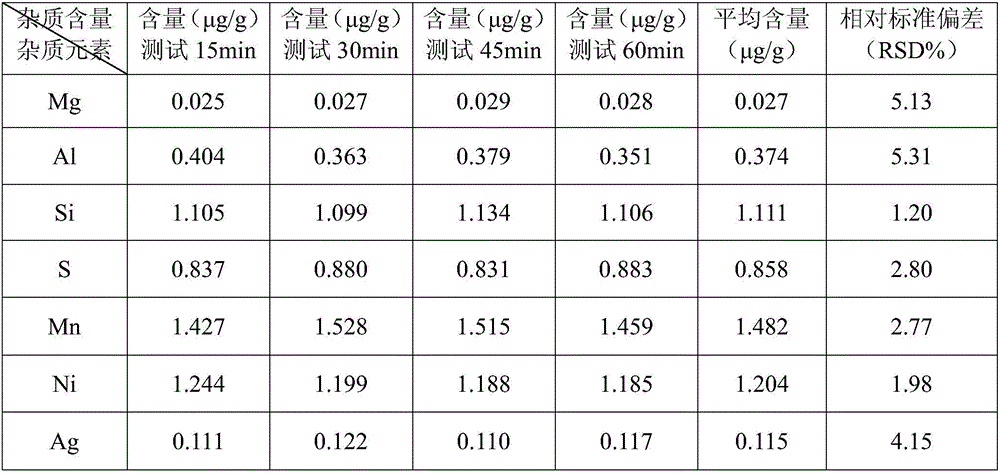

[0029] The method for detecting the content of trace impurity elements in high-purity copper (equivalent concentration ≥ 5N) by glow discharge mass spectrometry in the present embodiment includes the following steps:

[0030] The high-purity copper sample is processed into a tetrahedron with a thickness of 3.5mm, a length of 21mm and a width of 18mm, and the sample is placed in a nitric acid solution with a volume concentration of 28%. Ultrasonic cleaning, washing with pure water, repeated ultrasonic cleaning and pure water washing, then washing with absolute ethanol, drying for use;

[0031] Vacuum the sample chamber of the glow discharge mass spectrometer, open the ball valve, push the dried sample into the ion source cavity, turn on the high voltage and glow, pass in argon, adjust the discharge voltage to 2.6KV, and the discharge current to 2.4 mA, perform ion source tuning, adjust the Beam Centering parameters to obtain the signal peak with the highest sensitivity; adjust ...

Embodiment 2

[0034] The method for detecting the content of trace impurity elements in high-purity copper (equivalent concentration ≥ 5N) by glow discharge mass spectrometry in the present embodiment includes the following steps:

[0035] The high-purity copper sample is processed into a tetrahedron with a thickness of 3mm, a length of 22mm and a width of 20mm. The sample is placed in a nitric acid solution with a volume concentration of 25%, and hydrofluoric acid accounting for 1wt% of the nitric acid solution can be added to perform ultrasonic waves. Cleaning, wash with pure water, repeat ultrasonic cleaning and pure water washing, then wash with absolute ethanol, dry for use;

[0036] Evacuate the sample chamber of the glow discharge mass spectrometer, open the ball valve, push the dried sample into the ion source cavity, turn on the high voltage and glow, pass in argon, adjust the discharge voltage to 2.6KV, and the discharge current to 2.6mA , perform ion source tuning, adjust the Bea...

Embodiment 3

[0039] The method for detecting the content of trace impurity elements in high-purity copper (equivalent concentration ≥ 5N) by glow discharge mass spectrometry in the present embodiment includes the following steps:

[0040] The high-purity copper sample is processed into a tetrahedron with a thickness of 2.6 mm, a length of 18 mm and a width of 16 mm, and the sample is placed in a nitric acid solution with a volume concentration of 30%. Ultrasonic cleaning, rinse with pure water, repeat ultrasonic cleaning and pure water cleaning, then rinse with absolute ethanol, and dry for use;

[0041] Vacuum the sample chamber of the glow discharge mass spectrometer, open the ball valve, push the dried sample into the ion source cavity, turn on the high voltage and glow, pass in argon, adjust the discharge voltage to 2.2KV, and the discharge current to 2.1mA , perform ion source tuning, adjust the Beam Centering parameters to obtain the signal peak with the highest sensitivity; adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com