F/Mn co-doped SnO2 nanopowder and preparation method thereof

A nano-powder and co-doping technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of uniform particle size, easy dispersion, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of F / Mn Co-doped SnO Using Hydrothermal Method 2 Nano powder, the specific steps are as follows: First, measure 50 ml of deionized water in a beaker, add citric acid to adjust the pH value to 1-2, and at the same time stir and heat to 50°C with a magnetic stirrer and keep it at a constant temperature; then add an appropriate amount of SnCl 4 ·5H 2 O to dissolve; and then different doping amount of MnSO 4 ·H 2 O and NH 4 F was added to the above solution. After continuing to stir for 10-30 min, gradually add the precipitating agent (ammonia, sodium hydroxide or potassium hydroxide) into the above solution and continue stirring for 10-30 min to adjust the pH value to 5-11, then add the dispersant (the addition of the dispersant Amount between 1% and 5%, according to SnCl 4 ·5H 2 O mass to calculate), the resulting mixed solution was transferred to a hydrothermal tank for hydrothermal reaction at different temperatures; then the hydrothermal reaction pro...

Embodiment 2

[0046] The selection of embodiment 2 precipitation agent

[0047] The doped F 0.05 mn 0.05 sn 0.90 o 2 Nano powder, after XRD test, the results are as follows: figure 1 shown.

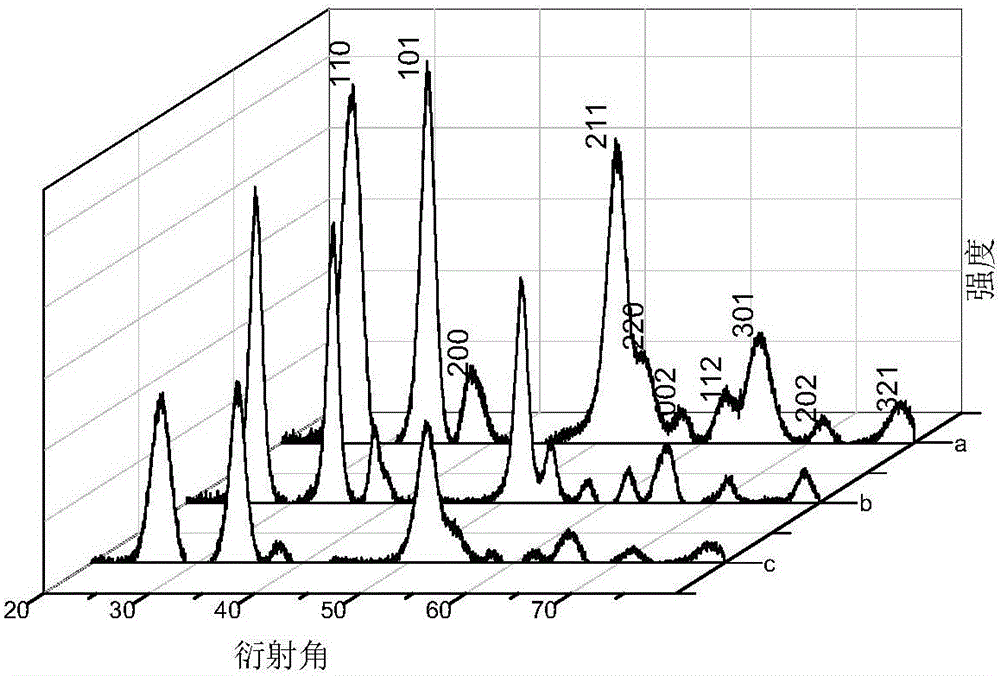

[0048] figure 1 For doped SnO prepared with different precipitants 2 The XRD pattern of the nanopowder, after being mixed with SnO 2 Compared with the standard card (PDF#-1445), the samples prepared with NaOH, KOH and ammonia water as precipitants all have a tetragonal rutile structure. Among them, the diffraction peaks on (220) and (002) crystal planes of the sample with ammonia water as the precipitant are not very clear, and the diffraction peaks on the (220) and (002) crystal planes of the sample with KOH as the precipitant are slightly more obvious, but in the The samples with NaOH as the precipitant have the clearest diffraction peaks on these two crystal planes, and the peak heights are the highest. At the same time, the diffraction peaks on the three crystal planes of the characteristic...

Embodiment 3

[0049] The selection of embodiment 3 dispersants

[0050] The other conditions of the experiment are certain (the molar ratio of each atom: F:Mn:Sn=0.05:0.05:0.90, pH=9, the hydrothermal temperature is 180°C, the hydrothermal time is 6 h, the precipitant is NaOH), and different Dispersant Preparation of Doped SnO 2 Nano powder, through SEM test such as figure 2 shown.

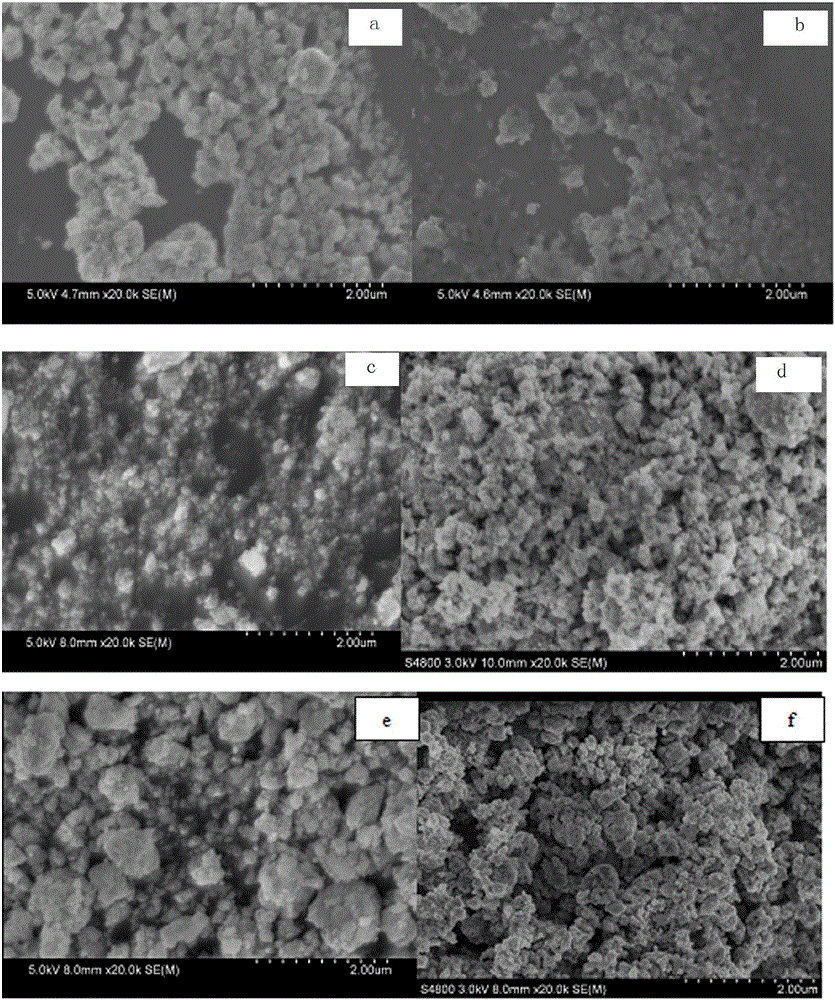

[0051] Depend on figure 2 As shown, the sample agglomeration without adding dispersant is particularly serious, wherein sodium stearate not only does not reach the dispersion effect, the sample agglomeration of its preparation is more serious than the sample without adding dispersant, is basically a block structure, adding SDS (12 Sodium alkylsulfonate) and TPAB (tetrapropylammonium bromide) as the dispersant have a coral-like appearance, but the dispersion effect is not very obvious. The surface of the sample prepared with PEG-600 as the dispersant looks like There is a layer of film covering the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com