Applications of porous silicon particles in visualization monitoring of wound pH value

A technology of porous silicon and particles, applied in the fields of application, diagnostic recording/measurement, medical science, etc., can solve the problems such as the need for receiving terminals, the system electrodes are easily polluted, the production process is cumbersome, etc., and the effect of good biocompatibility is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation method of porous silicon particles:

[0026] (1) Fix the P-type boron-doped silicon chip in the electrolytic cell, add organic solvent ethanol and hydrofluoric acid with a mass concentration of 30% as the electrolyte in a volume ratio of 1:3, use the silicon chip as the anode, platinum The electrode is the cathode, and the current density is 30mA·cm -1 Carry out constant current electrolysis for 10 minutes, and porous silicon is obtained;

[0027] (2) Continue etching, change the mass concentration of etching solution hydrofluoric acid to 3.3%, and the etching current density to 50mA cm -1 , and constant current etching was performed, and the porous silicon film was detached from the silicon substrate after 3 minutes.

[0028] (3) The porous silicon film obtained in step (2) was placed in ethanol and ultrasonically treated for 10 min to obtain micron-sized porous silicon particles.

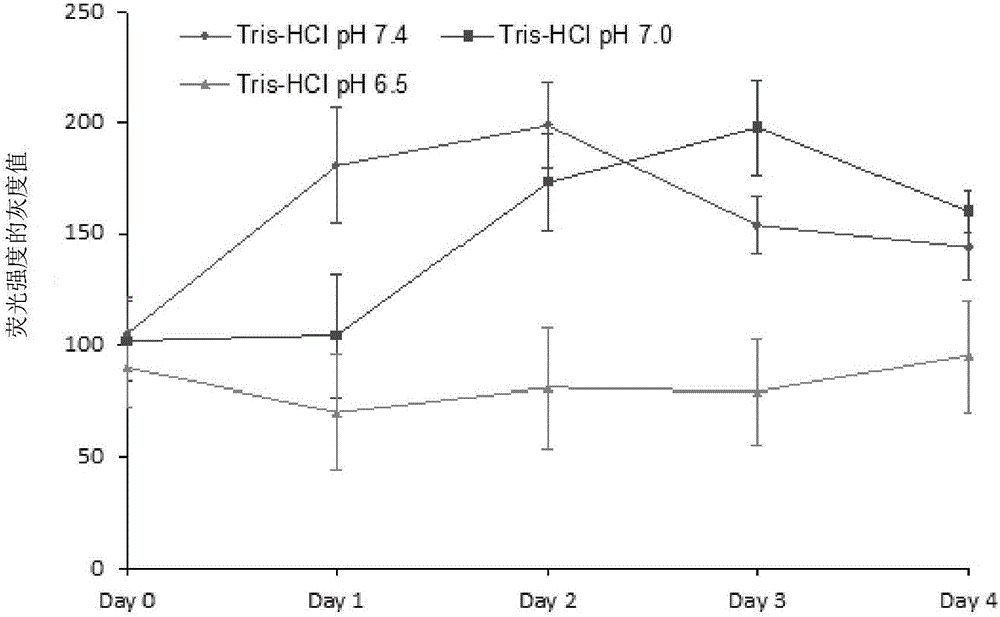

[0029] Visually distinguish the pH of the obtained fluorescent porous si...

Embodiment 2

[0031] Preparation of carboxylated porous silicon particles:

[0032] (1) using toluene as a solvent, preparing a mixed solution with a volume ratio of undecylenic acid and toluene of 1:8 to 15;

[0033] (2) Electrochemical preparation, non-ultrasonic dispersion of porous silicon particles in the above mixed solution, oil bath at 100-150 ° C, heating and reflux under nitrogen atmosphere, and reaction for 1.5-3 hours to obtain carboxylated porous silicon particles, After ultrasonication for 3-10 minutes, micron-sized porous silicon particles modified by carboxylation are obtained.

Embodiment 3

[0035] Preparation of porous silica particles modified by amination:

[0036] (1) Using DMOS (dimethyl sulfoxide) as a solvent, prepare a (3-aminopropyl)triethoxysilane DMSO solution with a volume fraction of 1 to 3%;

[0037] (2) After the ultrasonic particles are fluorescently activated in the phosphate solution, react in the above reaction solution in an anhydrous environment in a shaker for 10-30 minutes;

[0038] (3) Rinse the particles with DMSO, ethanol, and water respectively, and heat in air at 75-100° C. for 10-20 min to obtain aminated porous silicon particles.

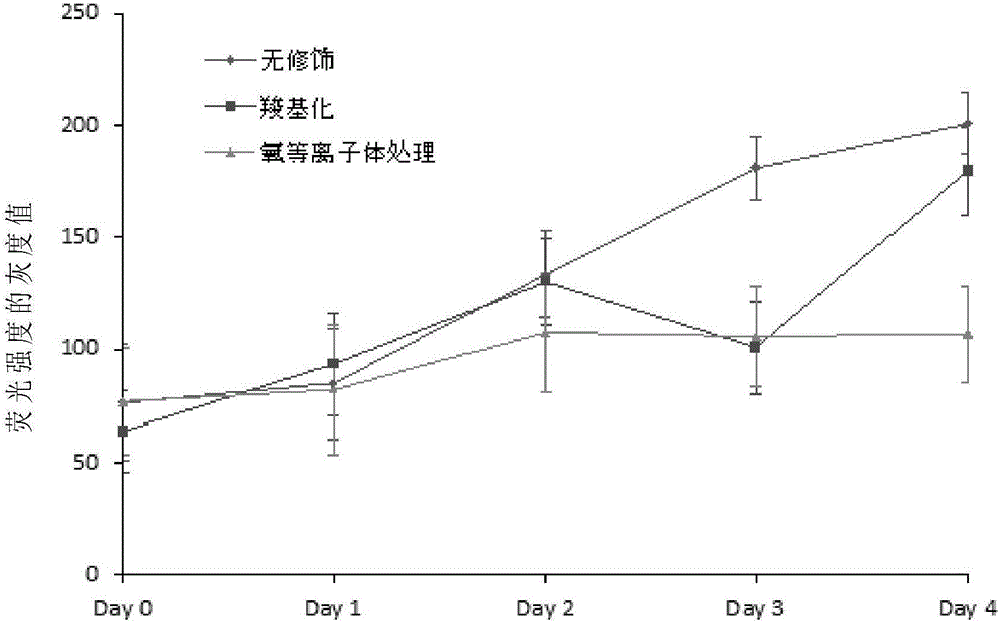

[0039] The three different porous silicon particles prepared in the above examples 1-3 were soaked in Na with a pH of 6.5 2 HPO 4 -NaH 2 PO 4 buffer (0.05M concentration). Using a UV lamp as the excitation light source, the gray value of the fluorescence intensity of porous silicon changes with time as figure 2 shown. It can be seen from the figure that under different surface chemical modifications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com