N-doped carbon-supported base metal oxygen reduction/oxygen evolution dual-function catalyst

A dual-function catalyst, non-precious metal technology, applied in structural parts, electrical components, battery electrodes, etc., to achieve the effect of simple operation and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

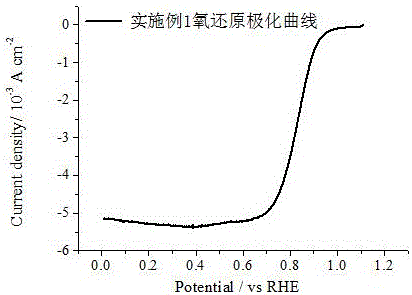

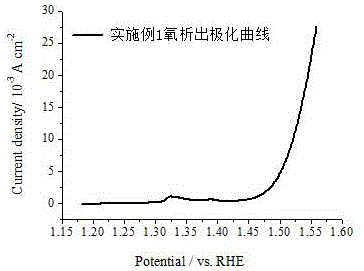

Embodiment 1

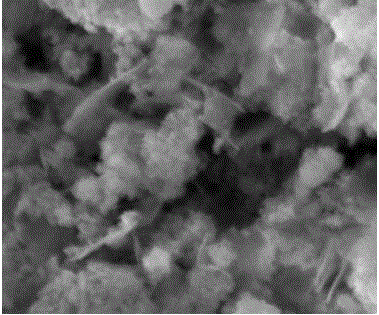

[0030] Step 1: Pour 200ml of concentrated sulfuric acid into a beaker, put the beaker in an ice bath and cool it below 4°C, weigh 10g of acetylene black (AB) powder and 5.0g of sodium nitrate into the beaker, and slowly add 10g of it after ultrasonic oscillation for 1 hour Potassium permanganate, turn off the ultrasonic vibration, use mechanical stirring instead, control the temperature not to exceed 10°C, and react for 2 hours, raise the temperature of the water bath to 40°C and react for 0.5 hours. Afterwards, the mixed solution was slowly added into 1000 ml of deionized water, and then the mixed solution was placed in a 95° C. water bath and reacted for 30 minutes under stirring. After the high temperature reaction, add 500 ml of deionized water to stop the reaction, then add 150 ml (30 vol%) of hydrogen peroxide, react for 15 minutes, and then add 300 ml (10 vol%) of hydrochloric acid. The mixture was centrifuged, washed with deionized water several times until neutral, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com