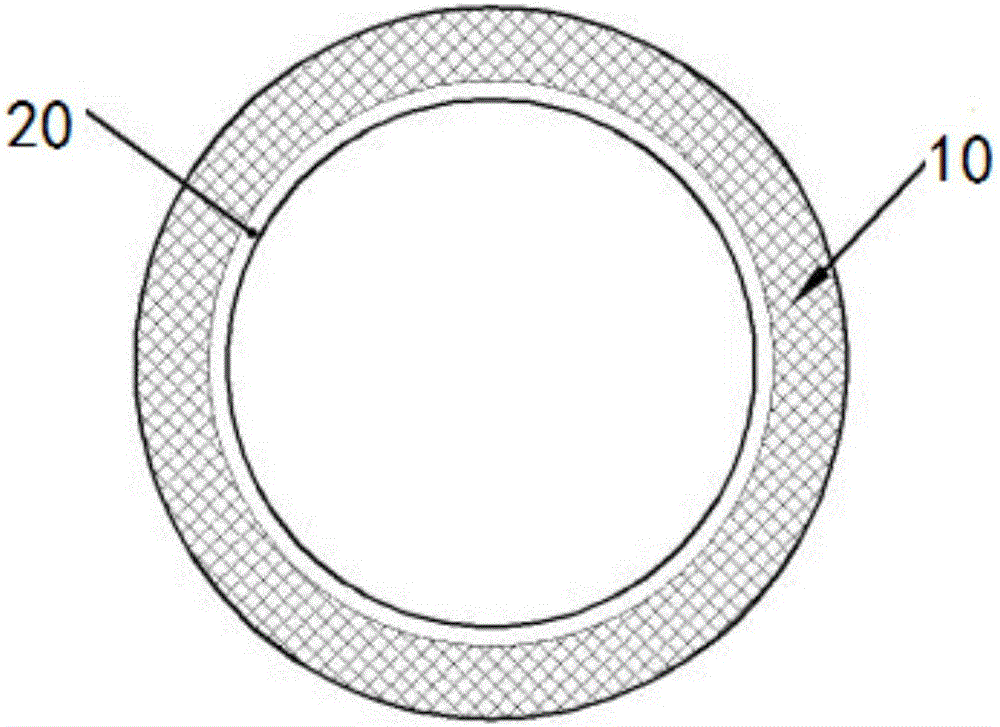

Single-wall heat-shrinkable tube and preparation method thereof

A heat-shrinkable sleeve and copolymer technology, used in tubular articles, other household appliances, applications, etc., can solve problems such as poor sealing performance, achieve excellent sealing performance, significant economic and social benefits, and improve performance and application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] raw material:

[0026] Calculated in parts by weight, take 50 parts of ethylene vinyl acetate copolymer with a melt index of 1-5g / 10min, 14 parts of ethylene vinyl acetate copolymer with a melt index of 10-20g / 10min, and a melt index of 20-40g / 10min 10 parts of ethylene vinyl acetate copolymer, environmentally friendly flame retardants include 10 parts of magnesium hydroxide, 10 parts of aluminum hydroxide, tackifiers include 1.5 parts of terpene resin, 0.5 parts of rosin resin, lubricants include 0.2 parts of PE wax , 0.3 part of zinc stearate, colorant includes 2 parts of carbon black, 2 parts of organic pigment, antioxidant includes tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.2 parts, 0.3 parts of tris[2,4-di-tert-butylphenyl]phosphite.

[0027] Preparation:

[0028] Granulation: After the above-mentioned raw materials are fully mixed by a high-speed mixer, they are blended and granulated by an internal mixer or a twin-screw ...

Embodiment 2

[0033] raw material:

[0034] Calculated in parts by weight, take 40 parts of ethylene vinyl acetate copolymer with a melt index of 1-5g / 10min, 13 parts of ethylene vinyl acetate copolymer with a melt index of 10-20g / 10min, and a melt index of 20-40g / 10min 15 parts of ethylene vinyl acetate copolymer, environment-friendly flame retardant including 5 parts of silicate, 15 parts of ammonium phosphate, 5 parts of ammonium dihydrogen phosphate, tackifier including 1 part of terpene resin, 1 part of rosin resin, petroleum 1 part of resin, 0.1 part of lubricant including silicone, 0.1 part of silicone oil, 1 part of colorant including iron oxide, 1 part of titanium dioxide, 1 part of organic pigment, antioxidant including tris[2,4-di-tert-butylphenyl ] 0.2 parts of phosphite, 0.3 parts of di(octadecyl) thiodipropionate, 0.3 parts of 4,4'-methylene bis(2,6-di-tert-butylphenol).

[0035] Preparation:

[0036] Granulation: After weighing the raw materials according to the above formu...

Embodiment 3

[0041] raw material:

[0042]Calculated in parts by weight, take 35 parts of ethylene vinyl acetate copolymer with a melt index of 1-5g / 10min, 20 parts of ethylene vinyl acetate copolymer with a melt index of 10-20g / 10min, and ethylene vinyl acetate copolymer with a melt index of 20-40g / 10min. 9 parts of vinyl acetate copolymer, environmentally friendly flame retardants include 15 parts of ammonium dihydrogen phosphate, 15 parts of melamine, tackifiers include 1 part of terpene resin, 1 part of petroleum resin, lubricants include 0.5 parts of silicone oil, ethylene bis 0.5 part of stearic acid amide, 0.2 part of colorant including carbon black, 1.8 part of titanium oxide, 0.6 part of antioxidant including 4,4'-methylene bis(2,6-di-tert-butylphenol), N,N 0.4 parts of '-bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine.

[0043] Preparation:

[0044] Granulation: After weighing the raw materials according to the above formula, they are fully mixed evenly by a high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com