Chlorosulfonated polyethylene coating adhesive cement and preparation method thereof

A technology of chlorosulfonated polyethylene and mucilage, which is applied in the textile field and can solve the problem of a large amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

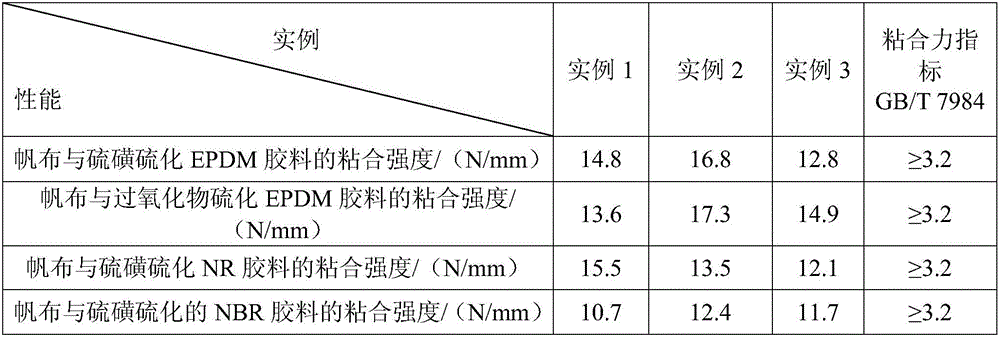

Examples

Embodiment 1

[0023] The raw materials for preparing the glue formula for coating the dipped canvas for conveyor belts include: 10 kg of chlorosulfonated polyethylene rubber, supplemented by 300 g of carbon black and 2500 g of white carbon black A total of 2800 grams of strong fillers, 25 grams of sulfur, 1000 grams of maleic anhydride polybutadiene, 400 grams of epoxy resin, 60 grams of imidazole epoxy curing agent, composed of 300 grams of nano zinc oxide and 50 grams of stearin A total of 350 grams of vulcanization activator composed of acid, a total of 150 grams of vulcanization accelerator composed of 100 grams of sulfenamide accelerator CZ and 50 grams of thiazole accelerator DM, NN m-phenylene bismaleimide is 600 grams, the antioxidant composed of 100 grams of antioxidant RD and 100 grams of antioxidant MB totals 200 grams, the plasticizer composed of 500 grams of DOP and 500 grams of aromatic oil totals 1000 grams, and is composed of 60 kilograms of toluene and 60 kilograms of xylene ...

Embodiment 2

[0029] The raw materials prepared for the preparation of the glue formula for the coating of dipped canvas for conveyor belts include: 10 kilograms of chlorosulfonated polyethylene rubber, 3000 grams of white carbon black, 150 grams of sulfur, and 1800 grams of horses. Acid anhydride polybutadiene, epoxy resin 1000 grams, imidazole epoxy curing agent 150 grams, vulcanization activator composed of 800 grams of nano zinc oxide and 100 grams of stearic acid, a total of 900 grams, 200 grams of sulfene Amide accelerator CZ, 200 grams of antioxidant MB, 1000 grams of NN meta-phenylene bismaleimide, 2000 grams of aromatic oil, 120 kilograms of toluene.

[0030] (1) Preparation of one-stage mixed rubber: Take 10 kg of chlorosulfonated polyethylene rubber and put it into an internal mixer for mixing for 2 minutes. After mixing, open the top plug, put 3000 grams of white carbon black, 1800 grams of maleic anhydride polybutadiene, 1000 grams of epoxy resin, 800 grams of nano zinc oxide and ...

Embodiment 3

[0035] Raw materials for the preparation of glue formulations for coating dipped canvases for conveyor belts, including: 10 kg of chlorosulfonated polyethylene rubber, filling supplements composed of 3000 g of carbon black and 2800 g of white carbon black A total of 5800 grams of strong agent, 100 grams of sulfur, 2300 grams of maleic anhydride polybutadiene, 1300 grams of epoxy resin, 100 grams of imidazole epoxy curing agent, composed of 1000 grams of nano zinc oxide and 300 grams of A total of 1300 grams of vulcanization activator composed of stearic acid, 200 grams of thiazole accelerator DM, a total of 400 grams of antioxidant composed of 200 grams of antioxidant MB and 200 grams of antioxidant MC, and 800 grams of NN m-phenylene bismaleic Imide, 2000 g DOP, 150 kg methylene chloride.

[0036] (1) Preparation of one-stage mixed rubber: Take 10 kg of chlorosulfonated polyethylene rubber and put it into an internal mixer for mixing for 2 minutes. After banburying, open the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com