Radiation-resistant flame-retardant cable insulation material and preparing method thereof

A flame-retardant cable and insulating material technology, applied in the direction of insulated conductors, insulated cables, rubber insulators, etc., can solve the problems of being unable to cope with harsh radiation environmental conditions, reducing the physical and mechanical properties of insulating materials, and affecting the normal operation of nuclear power plants, etc., to achieve excellent durability Radiation properties, good tensile and wear resistance properties, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

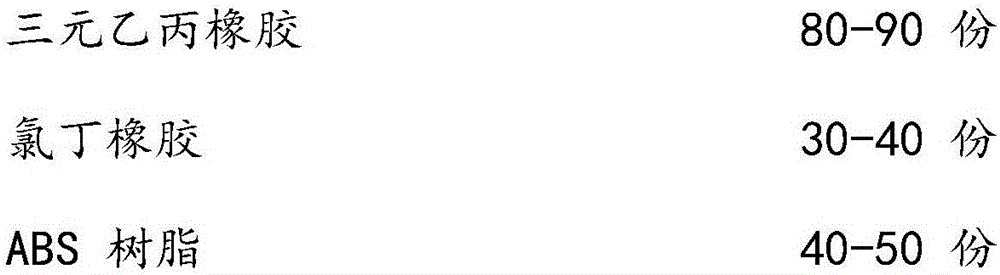

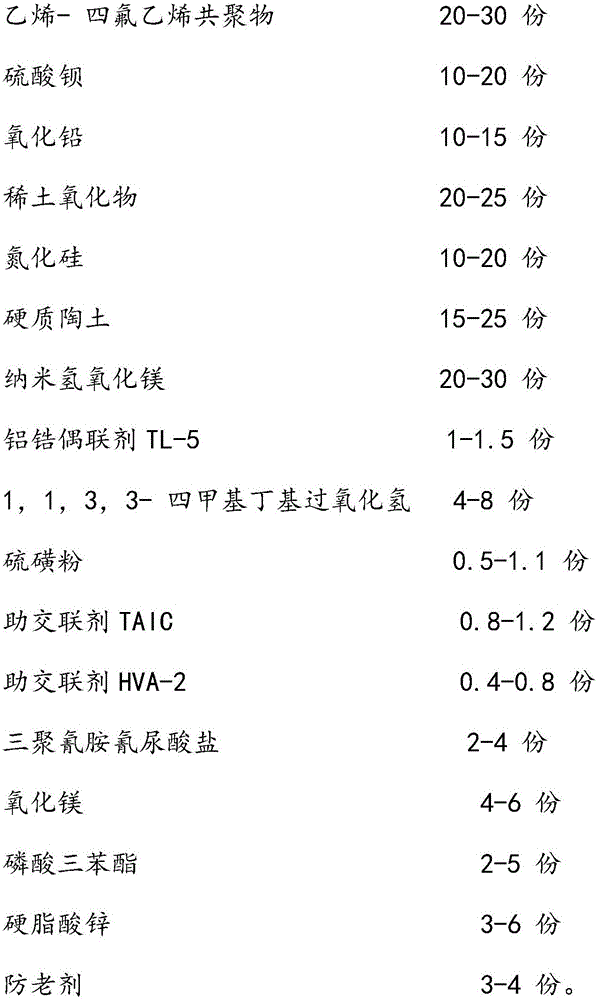

[0024] The invention proposes a radiation-resistant and flame-retardant cable insulation material, the raw materials of which include by weight:

[0025] EPDM rubber 80 parts, neoprene rubber 30 parts, ABS resin 40 parts, ethylene-tetrafluoroethylene copolymer 20 parts, barium sulfate 10 parts, lead oxide 10 parts, rare earth oxide 20 parts, silicon nitride 10 parts , 15 parts of hard clay, 20 parts of nano-magnesium hydroxide, 1-1.5 parts of aluminum-zirconium coupling agent TL-5, 4 parts of 1,1,3,3-tetramethylbutyl hydroperoxide, 0.5 parts of sulfur powder , 0.8 parts of cross-linking agent TAIC, 0.4 parts of cross-linking agent HVA-2, 2 parts of melamine cyanurate, 4 parts of magnesium oxide, 2 parts of triphenyl phosphate, 3 parts of zinc stearate, 3 parts of anti-aging agent share.

[0026] The invention also proposes a method for preparing the above-mentioned radiation-resistant and flame-retardant cable insulation material, which includes placing EPDM rubber, neoprene ...

Embodiment 2

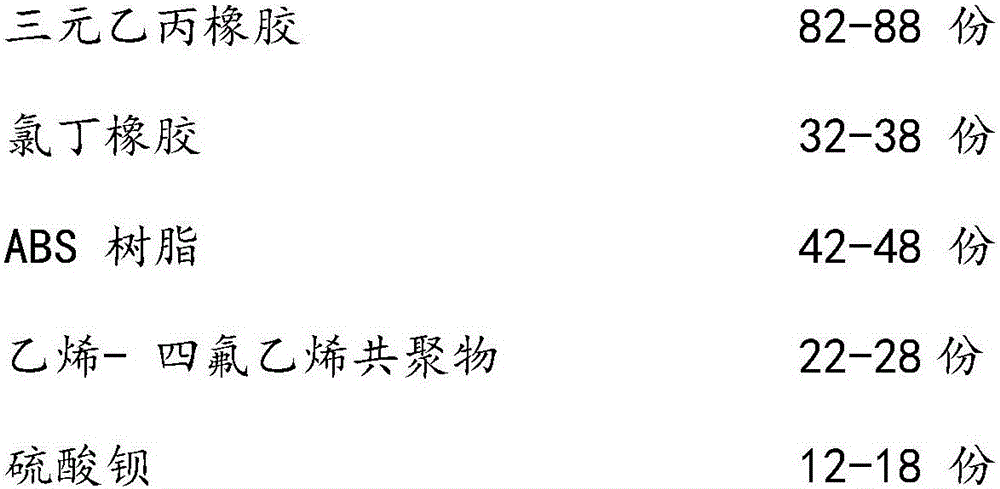

[0028] The invention proposes a radiation-resistant and flame-retardant cable insulation material, the raw materials of which include by weight:

[0029] EPDM rubber 85 parts, neoprene rubber 35 parts, ABS resin 45 parts, ethylene-tetrafluoroethylene copolymer 25 parts, barium sulfate 15 parts, lead oxide 13 parts, rare earth oxide 23 parts, silicon nitride 15 parts , 20 parts of hard clay, 25 parts of nano-magnesium hydroxide, 1.2 parts of aluminum-zirconium coupling agent TL-5, 6 parts of 1,1,3,3-tetramethylbutyl hydroperoxide, 0.8 parts of sulfur powder, 1 part of cross-linking agent TAIC, 0.6 parts of auxiliary cross-linking agent HVA-2, 3 parts of melamine cyanurate, 5 parts of magnesium oxide, 4 parts of triphenyl phosphate, 4 parts of zinc stearate, 3.5 parts of anti-aging agent.

[0030] The invention also proposes a method for preparing the above-mentioned radiation-resistant and flame-retardant cable insulation material, which includes placing EPDM rubber, neoprene r...

Embodiment 3

[0032] The invention proposes a radiation-resistant and flame-retardant cable insulation material, the raw materials of which include by weight:

[0033] 83 parts of EPDM rubber, 33 parts of neoprene rubber, 43 parts of ABS resin, 23 parts of ethylene-tetrafluoroethylene copolymer, 13 parts of barium sulfate, 13 parts of lead oxide, 22 parts of rare earth oxide, 13 parts of silicon nitride , 18 parts of hard clay, 22 parts of nano-magnesium hydroxide, 1.2 parts of aluminum-zirconium coupling agent TL-5, 5 parts of 1,1,3,3-tetramethylbutyl hydroperoxide, 0.7 parts of sulfur powder, 0.9 parts of cross-linking agent TAIC, 0.5 parts of auxiliary cross-linking agent HVA-2, 2.8 parts of melamine cyanurate, 4.8 parts of magnesium oxide, 3 parts of triphenyl phosphate, 4 parts of zinc stearate, and 3.3 parts of anti-aging agent.

[0034] The invention also proposes a method for preparing the above-mentioned radiation-resistant and flame-retardant cable insulation material, which inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com