Polyethylene anticorrosion adhesive tape with good soil stress resistance and preparation method thereof

A polyethylene and polyethylene-based film technology, applied in the direction of adhesives, epoxy resin glue, film/sheet adhesive, etc., can solve the problem of poor resistance to soil stress, affecting pipeline safety, and deterioration of anti-corrosion performance Poor and other problems, to achieve the effect of superior anti-corrosion performance, excellent anti-corrosion performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

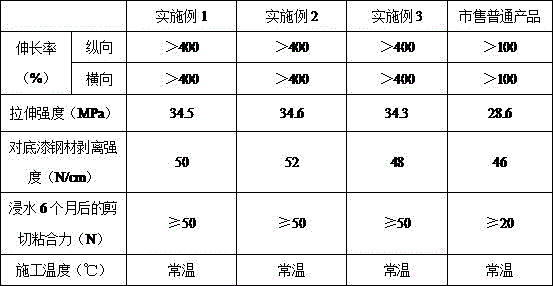

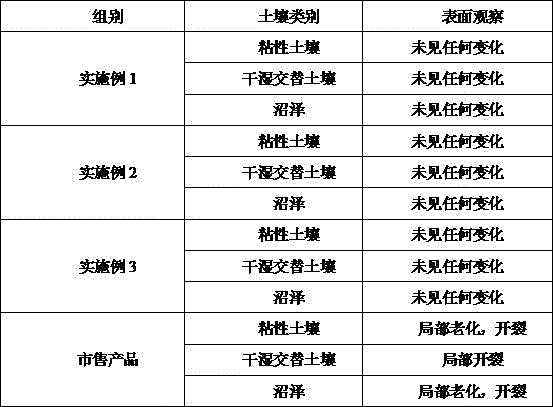

Embodiment 1

[0018] A polyethylene anti-corrosion adhesive tape with strong resistance to soil stress is composed of a polyethylene-based film and an adhesive layer, and the polyethylene-based film is made of the following raw materials in parts by weight: 50-80 parts of low-density polyethylene, 100-150 parts of high-density polyethylene, 1-3 parts of vinyl tri-tert-butoxysilane, 3-5 parts of bismaleimide, 15-20 parts of ethylene-vinyl acetate copolymer, 1 nano-silica -3 parts, 5-8 parts of antimony trioxide, 1-3 parts of accelerator DM, 1-3 parts of magnesium stearate, 10-15 parts of isocyanate; the adhesive layer is made of the following raw materials in parts by weight Ingredients: 80-100 parts of butyl rubber, 100-150 parts of bisphenol A epoxy resin, 3-5 parts of 2,6-di-tert-butyl-4 cresol, 1-3 parts of nano-zinc oxide, 1 part of magnesium oxide -3 parts, 1-2 parts of acetone, 15-20 parts of dibutyl phthalate, 1-3 parts of iron powder, 1-3 parts of boron powder, 3-8 parts of kaolin, ...

Embodiment 2

[0025] A polyethylene anti-corrosion tape with strong resistance to soil stress, which is composed of a polyethylene base film and an adhesive layer, the polyethylene base film is made of the following raw materials by weight: the polyethylene base film is made of the following weight 10 parts of raw materials: 65 parts of low-density polyethylene, 130 parts of high-density polyethylene, 2 parts of vinyl tri-tert-butoxysilane, 4 parts of bismaleimide, 18 parts of ethylene-vinyl acetate copolymer, 2 parts of nano silicon dioxide, 6 parts of antimony trioxide, 2 parts of accelerator DM, 2 parts of magnesium stearate, 12 parts of isocyanate; the adhesive layer is made of the following raw materials in parts by weight: butyl rubber 90 parts, 130 parts of bisphenol A epoxy resin, 4 parts of 2,6-di-tert-butyl-4 cresol, 2 parts of nano zinc oxide, 2 parts of magnesium oxide, 1.5 parts of acetone, dibutyl phthalate 18 parts, 2 parts of iron powder, 2 parts of boron powder, 5 parts of ...

Embodiment 3

[0032] A polyethylene anticorrosion adhesive tape with strong resistance to soil stress, which is composed of a polyethylene base film and an adhesive layer, and the polyethylene base film is made of the following raw materials in parts by weight: 80 parts of low density polyethylene, 80 parts of high density polyethylene 150 parts of polyethylene, 3 parts of vinyl tri-tert-butoxysilane, 5 parts of bismaleimide, 20 parts of ethylene-vinyl acetate copolymer, 3 parts of nano silicon dioxide, 8 parts of antimony trioxide, 3 parts of agent DM, 3 parts of magnesium stearate, and 15 parts of isocyanate; the adhesive layer is made of the following raw materials in parts by weight: 100 parts of butyl rubber, 150 parts of bisphenol A epoxy resin, 2, 5 parts of 6-di-tert-butyl-4 cresol, 3 parts of nano zinc oxide, 3 parts of magnesium oxide, 2 parts of acetone, 20 parts of dibutyl phthalate, 3 parts of iron powder, 3 parts of boron powder, 8 parts of kaolin 2 parts, crosslinking agent D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com