Preparation method for producing hydrogen electrode through efficient photoelectrocatalysis and application thereof

A photoelectric catalysis and hydrogen electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high production cost and low efficiency, achieve good light transmission, simplify the process flow, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

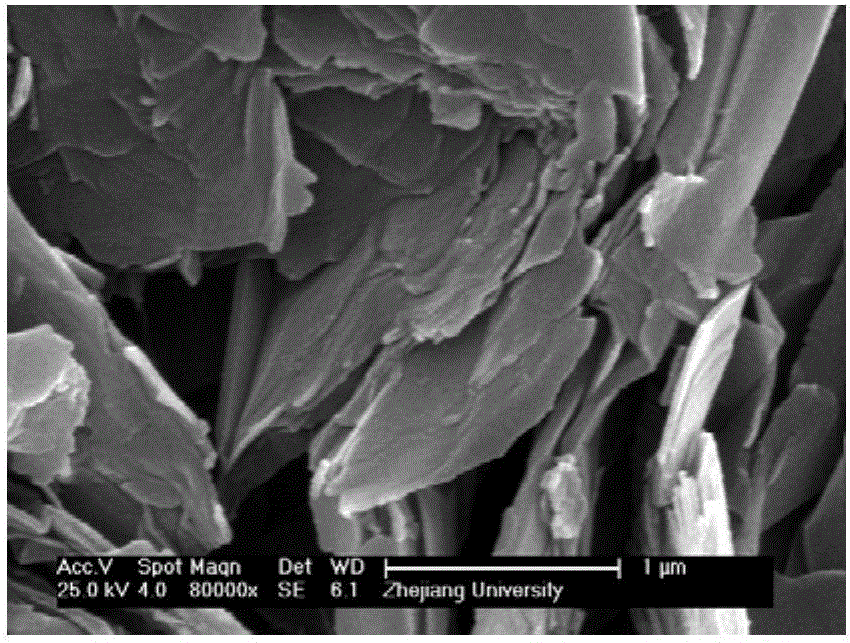

[0039] Set the geometric area to 0.2826 cm 2 The graphite flakes (diameter 0.6cm, thickness 0.1cm) were washed with deionized water, absolute ethanol and acetone for 30 minutes in order to remove organic matter on the surface. Placed in an oven, dried for 12 hours at 40 degrees, ready for use. The morphological picture of the blank graphite sheet obtained by scanning electron microscope is as follows Picture 1-1 Shown. The surface of the blank graphite sheet is composed of irregular flake graphite. Fix the dried graphite sheet with conductive silver glue on the bottom of the electrode rod (a PTFE shell with a conductive copper rod inside) as an electrode.

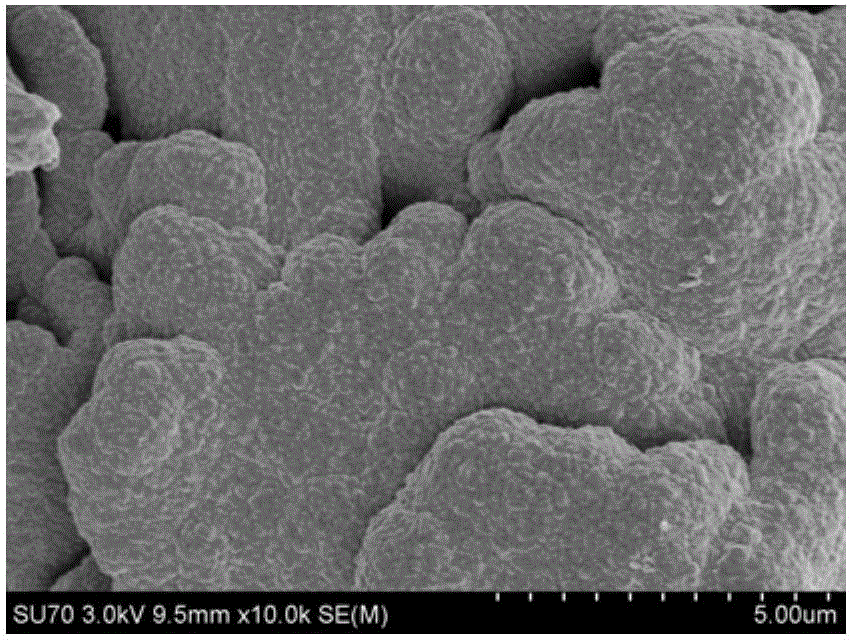

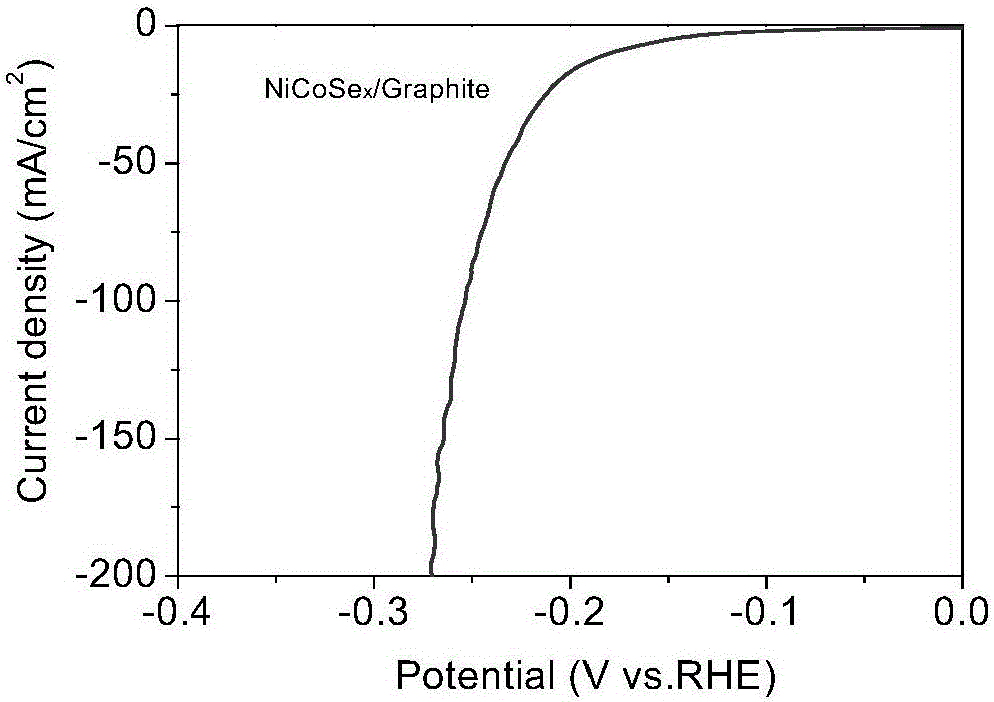

[0040] Graphite electrode is used as working electrode, Pt wire is used as counter electrode, and saturated calomel electrode is used as reference electrode. Electrolyte mother liquor is made of NiCl 2 • 6H 2 O, CoCl 2 • 6H 2 O, SeO 2 And KCl, the concentrations of which are 10 mmol / L, 10 mmol / L, 10 mmol / L and 50 mmol / L, resp...

Embodiment 2

[0043] Refer to the electrodeposition method in Example 1, using ITO conductive glass (5cm*2cm) as the working electrode, Pt sheet (1cm*1cm) as the counter electrode, and saturated calomel electrode as the reference electrode. The electrodeposition solution conditions are the same as those in Example 1. The same, the deposition time (0-180s) respectively, where the area of ITO immersed in the electrolyte is 2cm*2cm. NiCoSe prepared x / ITO electrode is rinsed with a large amount of ultrapure water, and placed in a vacuum oven at 30 degrees to dry for 12 hours.

[0044] NiCoSe with different deposition time x The light transmittance of the ITO sample is measured with a UV-spectrophotometer (UV-3150 UV-Vis), and the scanning range is 400-1200nm. The light transmittance data of samples with different deposition times are as follows figure 2 . It can be seen from the figure that as the deposition time increases, the color of the sample gradually becomes darker and the light transm...

Embodiment 3

[0046] Using cesium chloride nano-etching technology, monocrystalline silicon (P-type, boron-doped, (100) crystal plane) is prepared into p-Si nano-pillar arrays. The scanning electron microscope picture of a typical P-Si nano-pillar array is as follows Figure 3-1 , The column height is 1um, the average column diameter is 200nm, and the column spacing is 50-80nm.

[0047] Measure the reflectance with an ultraviolet-spectrophotometer (UV-3150 UV-Vis), and the scanning range is 400-1200nm. The reflectivity of intrinsic p-Si nanopillars varies with wavelength data as Figure 3-2 . Compared with planar p-Si, p-Si nanopillars show good light absorption properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com