High performance liquid chromatography-time-of-flight mass spectrometry method for identifying degradation product in compound cold treatment medicine based on heart-cutting technology

A high-performance liquid chromatography and time-of-flight mass spectrometry technology, applied in the field of analytical chemistry, can solve problems such as interference and pollution, and achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] a. Preparation of ibuprofen oxidation sample: take an appropriate amount of compound cold medicine (approximately equivalent to 200 mg of ibuprofen), add 10 ml of acetonitrile, dissolve it by ultrasonic, filter, add 10 ml of 30% hydrogen peroxide, put in a water bath at 80 ° C for 1 hour, Take it out, let it cool, transfer it to a 100ml measuring bottle, make it to volume, shake it up, filter it, and wait for sample injection.

[0078] b. Preparation of oxidized samples of phenylephrine hydrochloride and chlorpheniramine maleate: take an appropriate amount of compound cold medicine (approximately equivalent to 10 mg of phenylephrine hydrochloride and 4 mg of chlorpheniramine maleate), add 20% acetonitrile -Water solvent 10ml, ultrasonic to dissolve, shake well, add 5ml of 30% hydrogen peroxide, put in 80°C water bath for 30 minutes, take it out, let cool, transfer to 25ml measuring bottle, constant volume, shake well, filter, wait for sample injection .

Embodiment 1

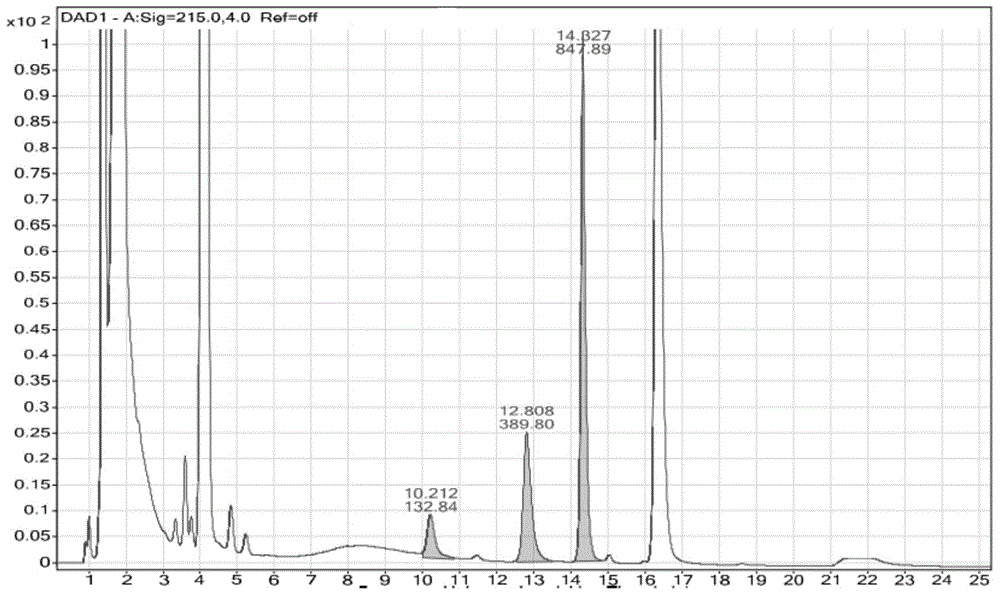

[0079] Example 1 Analysis of chlorpheniramine maleate and phenylephrine hydrochloride forced degradation products, cut as figure 1 When the middle retention time is 12.80 minutes, the instrument configuration and analysis conditions are:

[0080] One-dimensional:

[0081] High performance liquid chromatography: HPLC, Agilent 1260;

[0082] Chromatographic column: Waters spherisorb 5um SCX, 4.6*150mm;

[0083] Mobile phase A: 0.075mol / L disodium hydrogen phosphate (containing 0.1% triethylamine, adjust pH to 2.4 with phosphoric acid);

[0084] Mobile phase B: acetonitrile;

[0085] Linear Gradient:

[0086]

[0087] Detection wavelength: 215nm;

[0088] Flow rate: 1.0ml / min;

[0089] Column temperature: 35°C;

[0090] Injection volume: 20ul;

[0091] The valve switching time is 12.75-12.85min.

[0092]

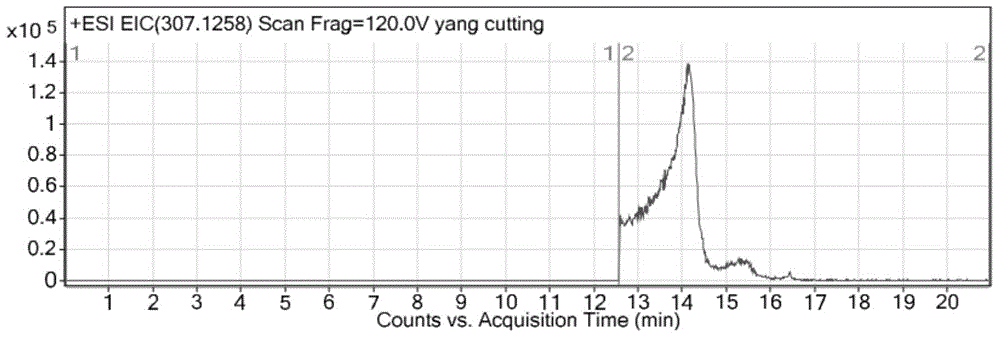

[0093] Cut 1D chromatograms (eg figure 1 ) when the retention time is a component of 12.80 minutes, the two-dimensional test conditions are as follows:

[0094...

Embodiment 2

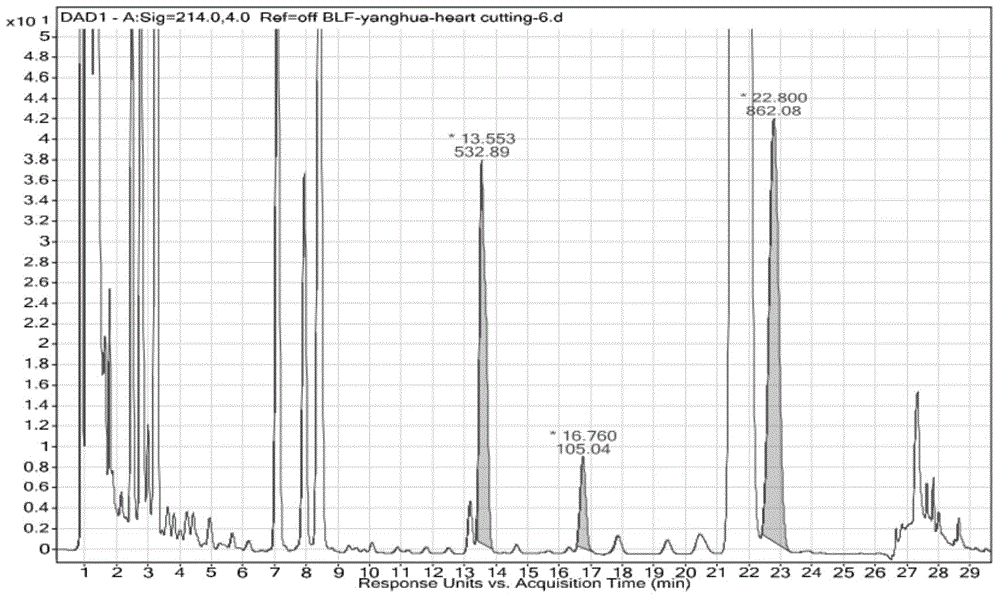

[0113] Example 2 Analysis of ibuprofen forced degradation products, cut as figure 2 When the middle component is 13.55 minutes, the instrument configuration and analysis conditions are:

[0114] One-dimensional:

[0115] High performance liquid chromatography: HPLC, Agilent 1260;

[0116] Chromatographic column: Waters BEH C18 3.5um 4.6*150mm;

[0117] Gradient elution conditions:

[0118] Mobile phase A: 0.02mol / L sodium dihydrogen phosphate (adjust the pH to 3.0 with phosphoric acid)-acetonitrile (83.5:16.5);

[0119] Mobile phase B: 0.02mol / L sodium dihydrogen phosphate (adjust the pH to 3.0 with phosphoric acid)-acetonitrile (16.5:83.5);

[0120] Linear Gradient:

[0121]

[0122] Detection wavelength: 214nm;

[0123] Flow rate: 1.4ml / min;

[0124] Column temperature: 35°C;

[0125] Injection volume: 20ul;

[0126] The valve switching time is 13.50-13.60min.

[0127]

[0128] Cut 1D chromatograms (eg figure 2 ), the two-dimensional test conditions are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| collision energy | aaaaa | aaaaa |

| mobile phase | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com