Preparation method and application method of targeted superparamagnetic nano-probe

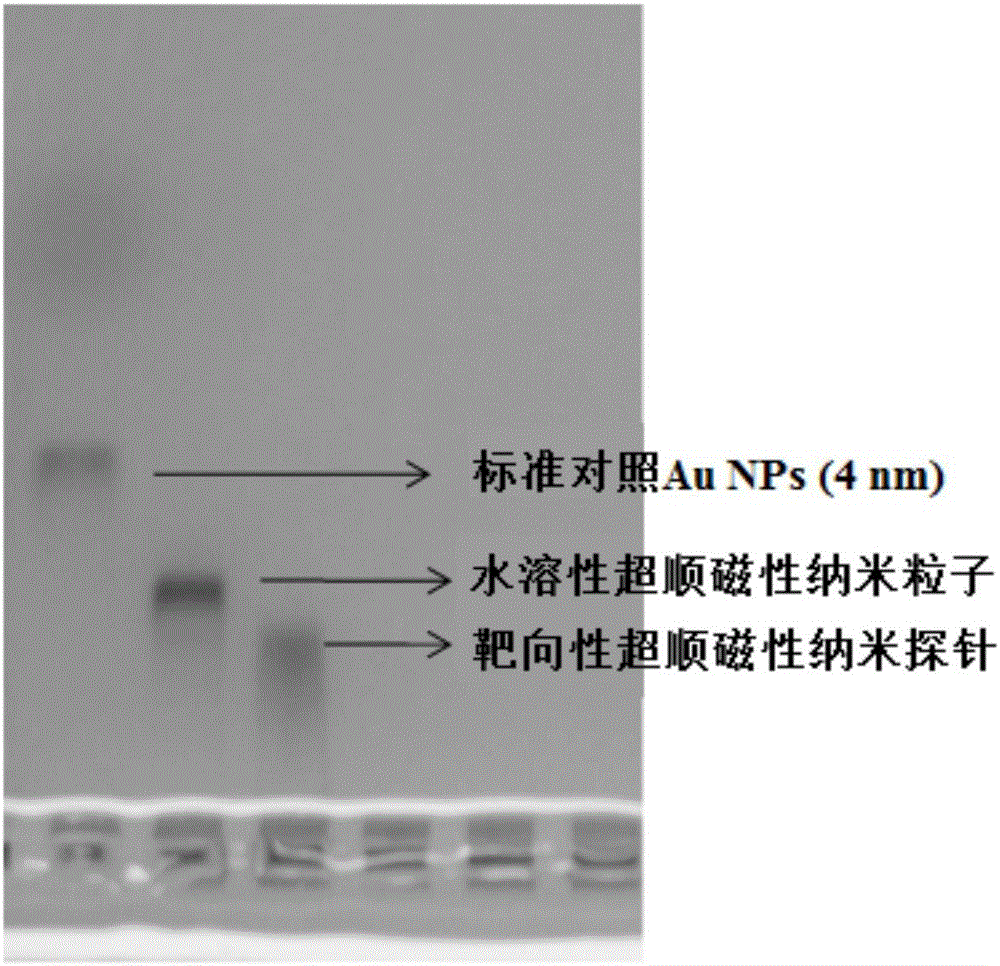

A superparamagnetic and nano-probe technology, applied in biochemical equipment and methods, using electricity/wave energy to treat microorganisms, electricity/wave energy to treat enzymes, etc., can solve the problem of uneven particle size distribution of magnetic nanoparticles, targeting In order to solve the problems of poor performance and low sensitivity, the cell capture rate is improved, the particle size distribution is uniform, and the cell capture rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

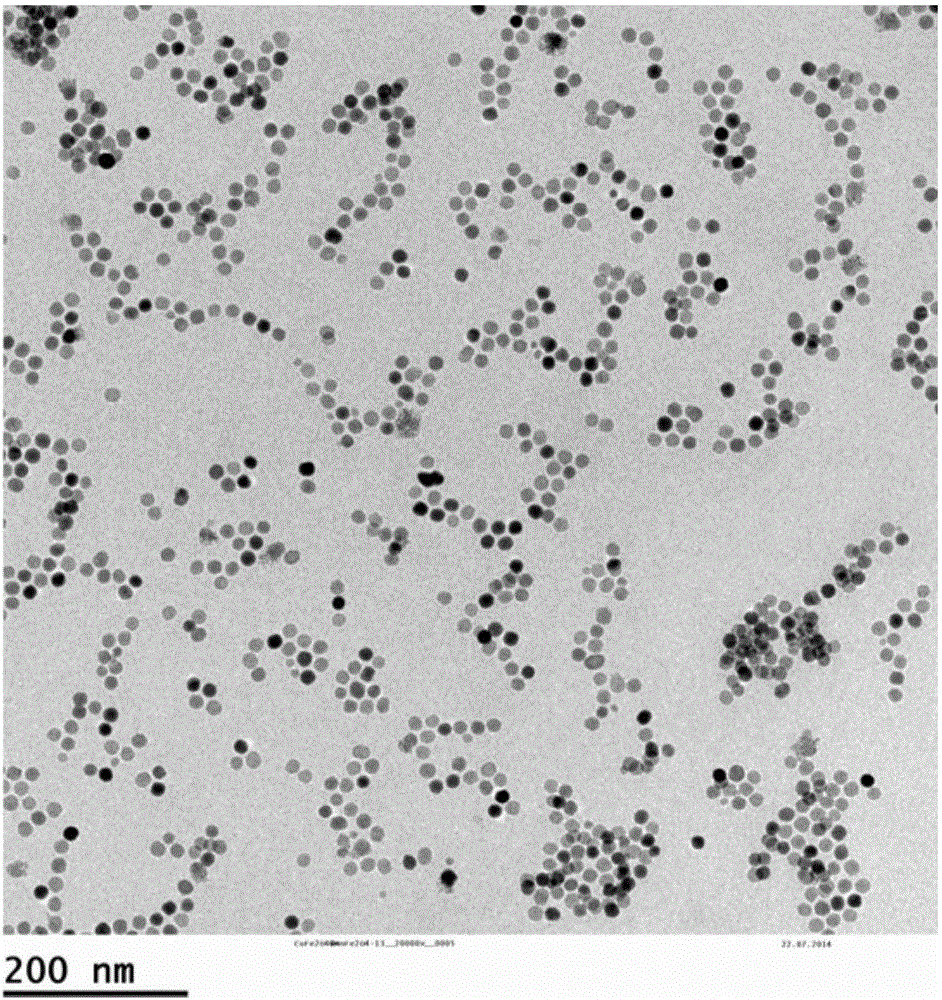

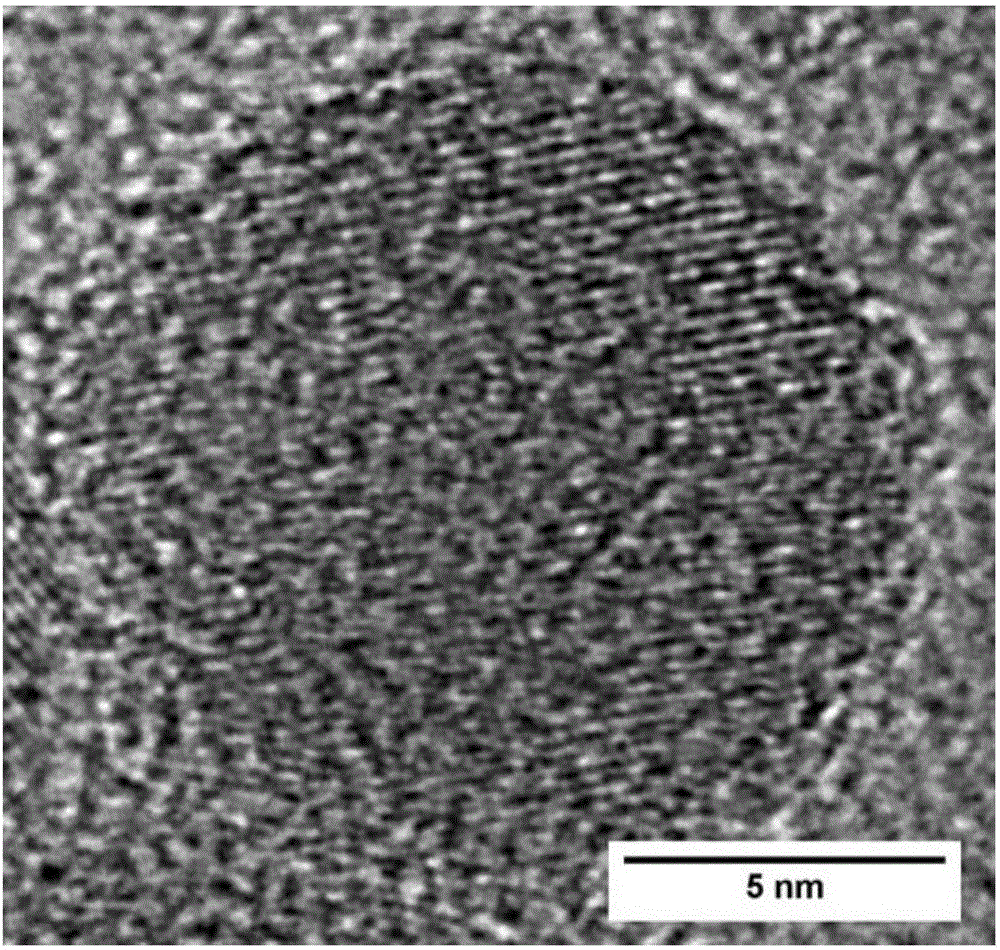

[0040] (1) In order to obtain monodisperse superparamagnetic nanoparticles, weigh 2mmol of ferric chloride, 10mmol of hexadecane glycol, 6mmol of oleylamine, 6mmol of oleic acid and 20mL of octadecene and mix them in 100mL of In a three-neck round bottom flask, under the protection of nitrogen and magnetic stirring, the mixture was heated to 200 °C using a heating mantle, and continued to heat at this temperature for 2 h, then continued to heat until boiling and maintained at this temperature for 2 h, and then removed the heating mantle to terminate the reaction. After cooling the obtained black liquid (i.e. product 1) to room temperature, add 10-30mL of absolute ethanol and centrifuge to precipitate (centrifugation condition: 2000rpm, 10min), the obtained black precipitate (i.e. product 2) was resuspended in chloroform After centrifugation and precipitation with ethanol again, the obtained samples were dispersed in chloroform for storage.

[0041] Using the sample (that is, ...

Embodiment 2

[0051] (1) In order to obtain monodisperse superparamagnetic nanoparticles, weigh 1mmol of iron acetylacetonate, 5mmol of hexadecane glycol, 4mmol of oleylamine, 4mmol of oleic acid and 10mL of dibenzyl ether and mix them in 100mL of In a three-necked round bottom flask, under the protection of nitrogen and magnetic stirring, the mixture was heated to 200 °C using a heating mantle, and continued to heat at this temperature for 3 h, then continued to heat until boiling and maintained at this temperature for 1 h, and then removed the heating mantle to terminate the reaction. After cooling the obtained black liquid (i.e. Product 1) to room temperature, add 10 mL of absolute ethanol and centrifuge to precipitate (centrifugation conditions: 2000 rpm, 10 min). After centrifugation, the obtained samples were dispersed in chloroform for storage.

[0052] Using the sample (that is, the obtained monodisperse superparamagnetic nanoparticles) as a reaction seed, larger-sized superparamag...

Embodiment 3

[0058] (1) In order to obtain monodisperse superparamagnetic nanoparticles, weigh 2mmol of iron oxide, 8mmol of hexadecane glycol, 2mmol of oleylamine, 2mmol of oleic acid and 15mL of diphenyl ether and mix them in 100mL of Tris In a round-bottomed flask, under the protection of nitrogen and magnetic stirring, the mixture was heated to 200 °C using a heating mantle, and continued to heat at this temperature for 2 h, then continued to heat until boiling and maintained this temperature for 2 h, and then removed the heating mantle to allow Its reaction terminates. After cooling the obtained black liquid (i.e. product 1) to room temperature, add 30mL of absolute ethanol and centrifuge to precipitate (centrifugation condition: 4000rpm, 10min), the obtained black precipitate (i.e. product 2) is resuspended in chloroform, and again After centrifugation, the obtained samples were dispersed in chloroform for storage.

[0059]Using the sample (that is, the obtained monodisperse superpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com