Manganous-manganic oxide/ cerium oxide composite nanotube, nanotube self-assembled film, and preparation method and application thereof

A technology of trimanganese tetroxide and self-assembled membrane, which is applied in the direction of manganese oxide/manganese hydroxide, chemical instruments and methods, nanotechnology, etc., can solve the problem of few nanotube membranes, achieve excellent results, simple process flow, and easy preparation Gentle and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is the preparation of manganese oxide nanofiber template, and the specific process is as follows:

[0047] First, 10 mmol of potassium sulfate (K 2 SO 4 ), 10mmol potassium persulfate (K 2 S 2 o 8 ) and 5mmol manganese sulfate monohydrate (MnSO 4 ·H 2 O) Add to 70mL deionized water, stir magnetically until fully dissolved to form a transparent mixed solution. Then this 70mL solution was transferred to a polytetrafluoroethylene reactor with a capacity of 125mL for hydrothermal reaction. The reaction temperature was 200°C, and the reaction time was 36 hours. After the reaction was completed, it was cooled to room temperature, and the obtained brown product was dispersed into 500 mL of deionized water, and magnetically stirred for 24 hours. Finally, filter with Buchner funnel and rinse with deionized water to remove impurity ions, and dry at 60° C. for 2 days to obtain the product (manganese oxide nanofiber material).

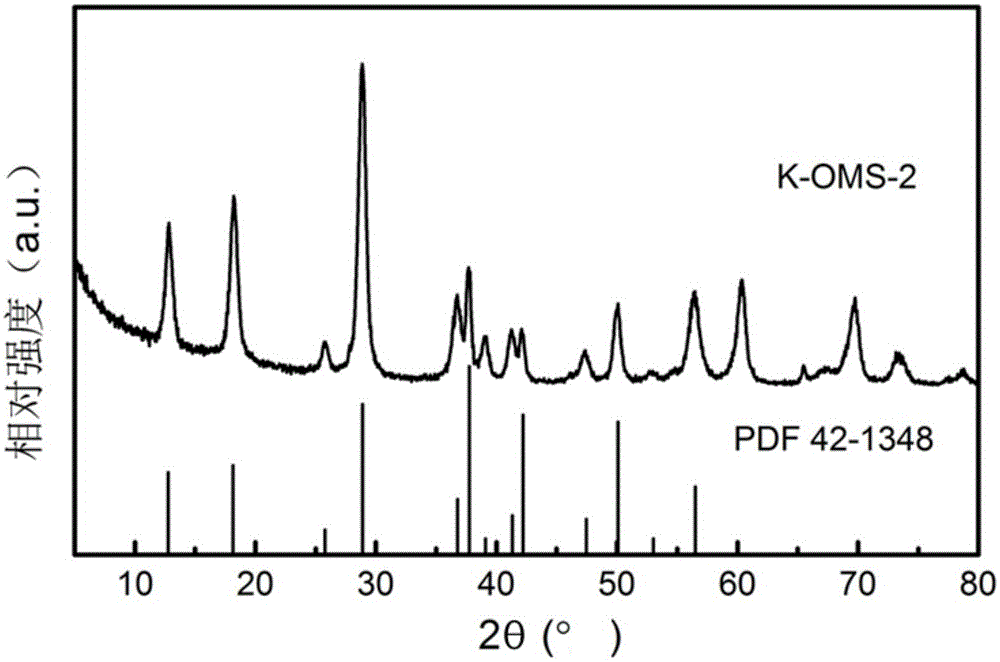

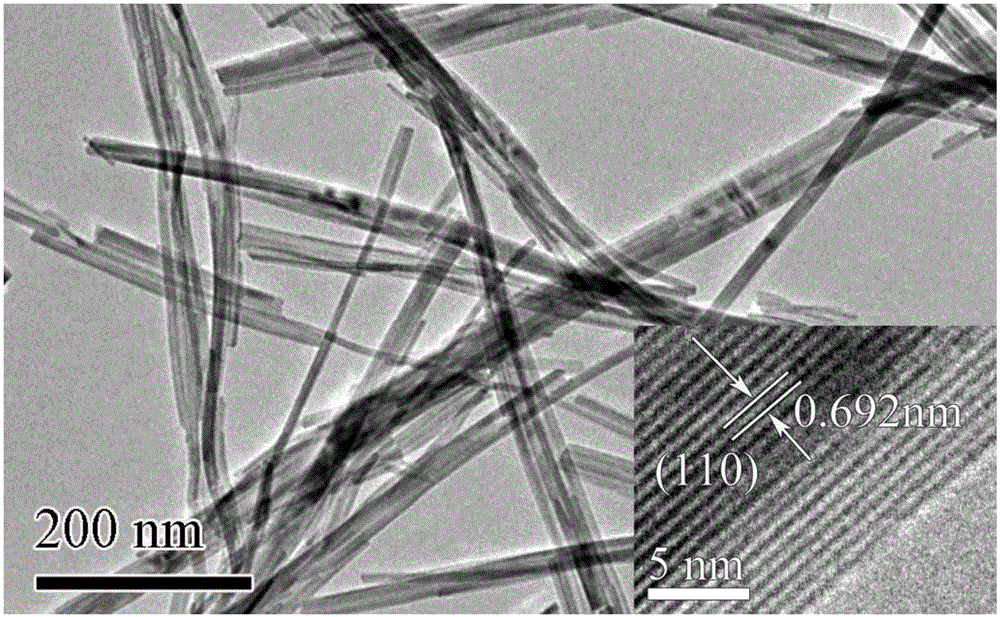

[0048] The nanofiber obtaine...

Embodiment 2

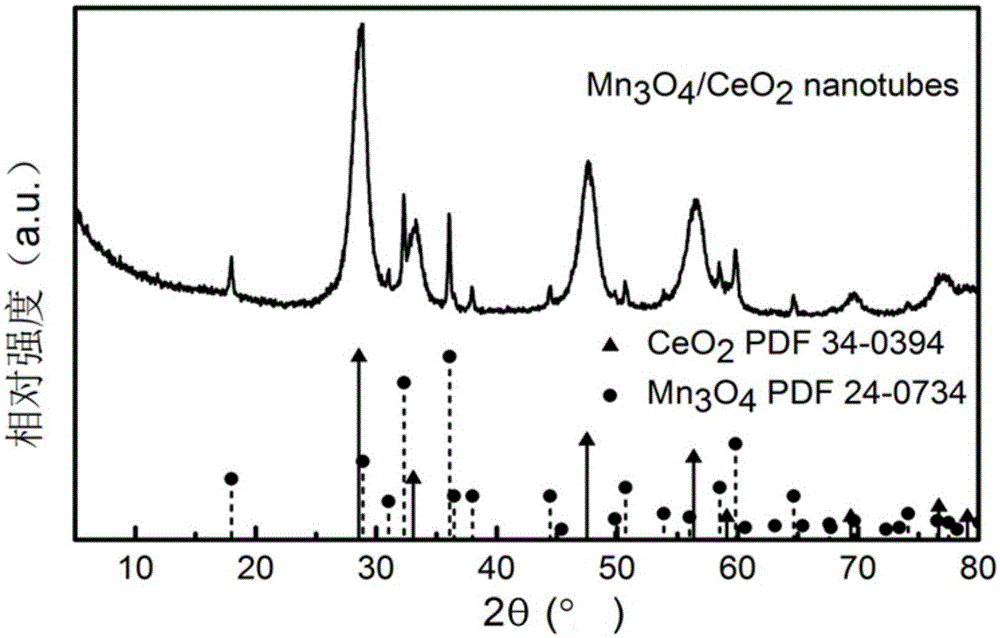

[0050] This embodiment is the preparation of composite nanotubes of manganese tetraoxide and cerium oxide, and the specific process is as follows:

[0051] First, put 0.3g of K-OMS-2 nanofibrous material prepared in Example 1 into a beaker filled with 300mL of deionized water, then transfer to an ultrasonic device for ultrasonication for 20 minutes, and then stir magnetically until a uniform flocculent suspension is formed. until the cloudy liquid. Then add 0.6g cerium nitrate (Ce(NO 3 ) 3 ), continue stirring for 20 minutes. Then add 5g hexamethylenetetramine (C 6 h 12 N 4 ) and stirred for about 20 minutes, and then put the mixture into a water bath and stirred at 90° C. for one hour. During this reaction, hexamethylenetetramine will undergo hydrolysis to maintain the pH of the solution at around 9. After one hour, a whitish precipitate formed at the bottom of the beaker. Finally, it was filtered with a vacuum Buchner funnel, washed with deionized water several times,...

Embodiment 3

[0054] This embodiment is the preparation of composite nanotube self-forming film of trimanganese tetraoxide and cerium oxide, and the specific process is as follows:

[0055] Disperse the manganese-cerium composite nanotubes prepared in Example 2 into deionized water, and stir with magnetic force for 4 hours until the nanotubes are fully dispersed. Then, the nanotube was separated from the liquid phase through a Buchner funnel by using a vacuum filtration device, and a film layer of the composite was obtained on filter paper, and dried at 40° C. to obtain a self-supporting film material, which was reserved for use.

[0056] Figure 5 Shown is a schematic diagram of the nanotube film formation process. Figure 6 Shown is the SEM picture of the membrane surface formed by composite nanotubes, and it can be seen that the membrane is interwoven with nanotube fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com