Polymer material having acid-base discoloration indication function, and preparation method and application thereof

A polymer material and polymer technology, which is applied in material analysis by observing the influence of chemical indicators, analysis by chemical reaction of materials, and material analysis, can solve the problem of cumbersome testing of small molecule indicators, pH value The high price of testing equipment, inconvenient maintenance and calibration, etc., achieve the effect of easy processing and application, excellent mechanical properties, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

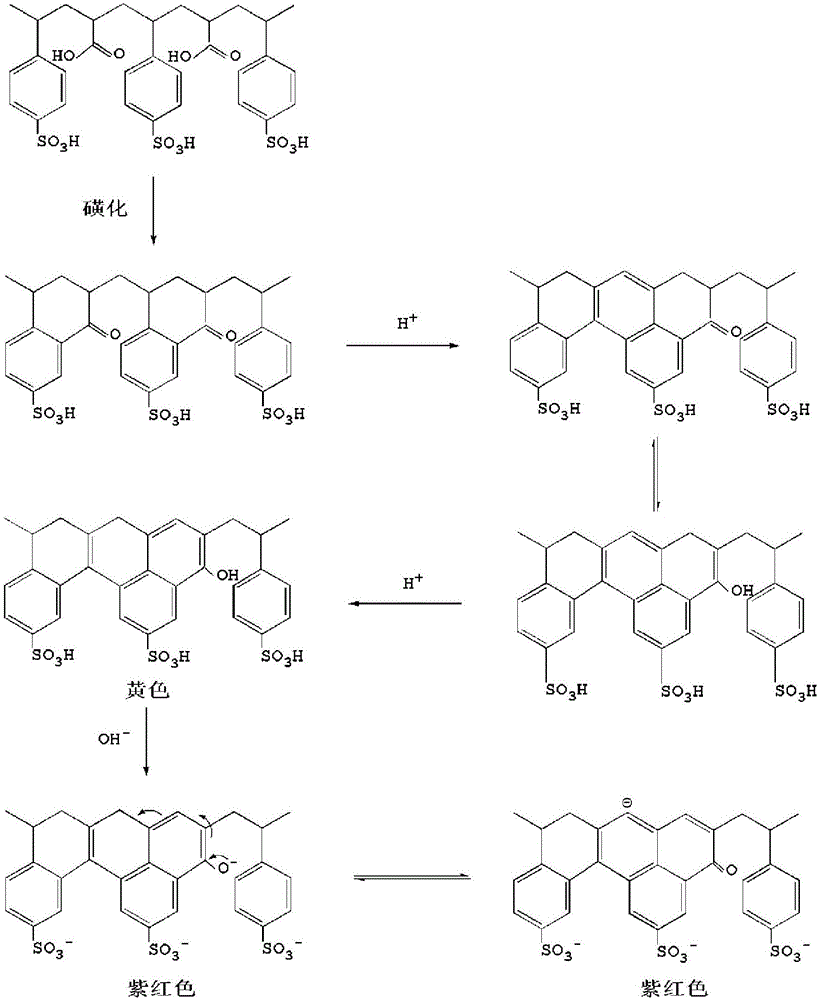

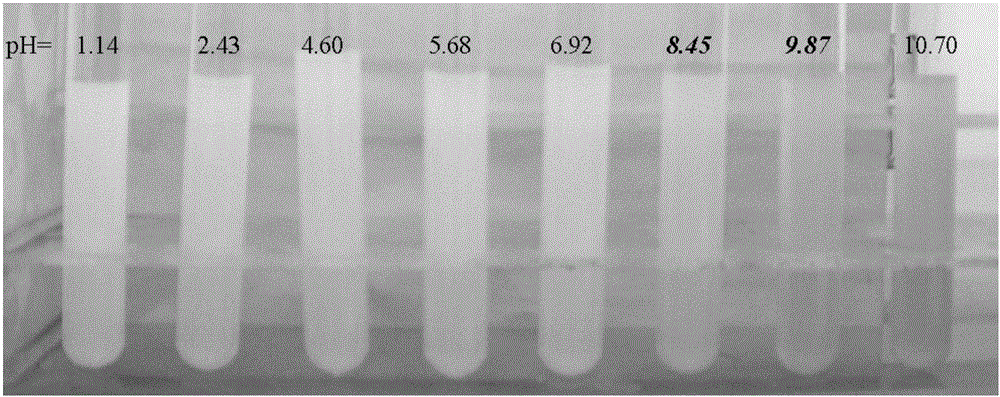

Method used

Image

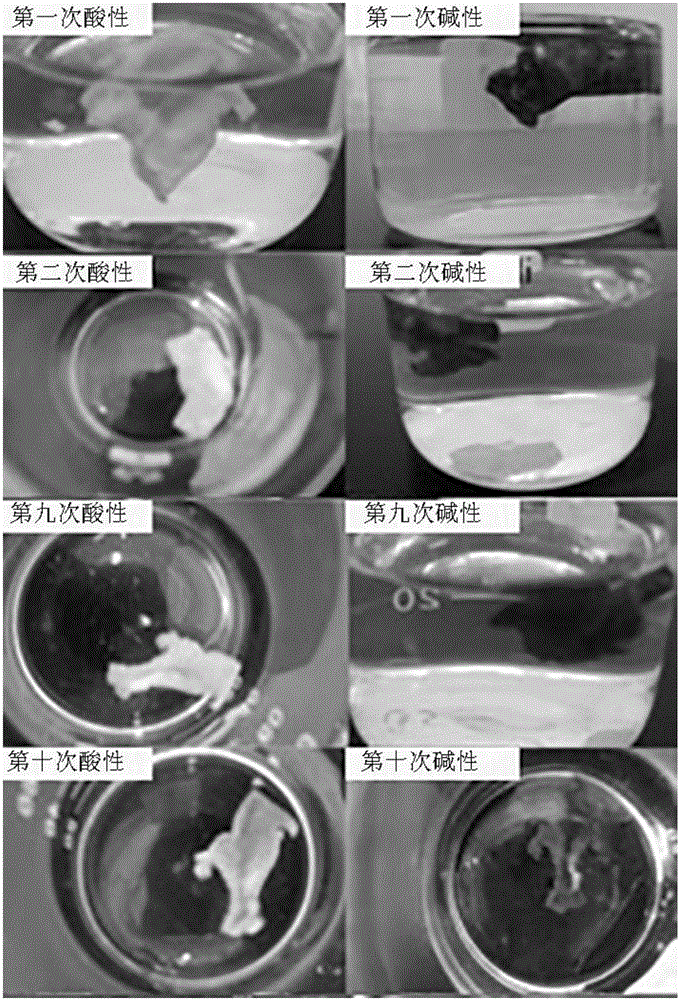

Examples

Embodiment 1

[0029] A preparation method of a polymer material with an acid-base discoloration indicating function, the specific preparation method is as follows:

[0030] (1) Weigh 182.0 grams of styrene monomer, 18.0 grams of acrylic acid monomer and 2.0 grams of sodium chloride and dissolve them in 1800 milliliters of water, and after heating up to 80 degrees Celsius, keep for about 10 minutes, add 2.0 grams of ammonium persulfate 200 milliliters of aqueous solution initiated polymerization. After 8 hours of polymerization, 10 milliliters of aqueous solution containing 1.0 gram of ammonium persulfate was added and the temperature was raised to 85 degrees Celsius for 30 minutes, then the reaction was stopped. The theoretical glass transition temperature of the polymer is 100.53 degrees Celsius, and it is dried at 70 degrees Celsius to obtain a powder product.

[0031] (2) Add 50 grams of magnesium sulfate heptahydrate to the emulsion in step (1) to break the emulsion, then filter the preci...

Embodiment 2

[0035] A preparation method of a polymer material with an acid-base discoloration indicating function, the specific preparation method is as follows:

[0036] (1) Weigh 182.0 grams of styrene monomer, 18.0 grams of acrylic acid monomer and 2.0 grams of sodium chloride and dissolve them in 1800 milliliters of water, and heat up to 30 degrees Celsius. 100 milliliters of aqueous solution containing 2.0 grams of ammonium persulfate and 100 milliliters of aqueous solution containing 2.0 grams of sodium ascorbate were added dropwise to the system to initiate polymerization, and the addition time was 4 hours and the reaction was continued for 1 hour. Then, 5 ml of aqueous solution containing 1.0 g of tert-butyl hydroperoxide and 5 ml of aqueous solution containing 1.0 g of sodium formaldehyde sulfoxylate were added respectively, and kept for 30 minutes, then the reaction was stopped. The theoretical glass transition temperature of the polymer is 100.53 degrees Celsius, and it is drie...

Embodiment 3

[0040] A preparation method of a polymer material with an acid-base discoloration indicating function, the specific preparation method is as follows:

[0041] (1) Dissolve 91.0 grams of styrene monomer, 91.0 grams of butyl acrylate monomer, 18.0 grams of acrylic acid monomer and 2.0 grams of sodium chloride in 1800 milliliters of water, and heat up to 80 degrees Celsius for about 10 minutes. Add 200 milliliters of aqueous solutions containing 2.0 grams of ammonium persulfate to initiate polymerization. After 8 hours of polymerization, add 10 milliliters of aqueous solutions containing 1.0 grams of ammonium persulfate and heat up to 85 degrees Celsius for 30 minutes to stop the reaction. The theoretical glass transition temperature of the polymer is 8.37 degrees Celsius, and a continuous polymer film is obtained by drying at 70 degrees Celsius. (2) Take 50 grams of the emulsion and pour it into a glass petri dish, and dry it in an oven at 70 degrees Celsius to obtain a polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com