Aureobasidium pullulans alb1 gene knockout mutant strain and its application

A technique of Aureobasidium pullulans and gene knockout, applied in the field of genetic engineering, can solve the problems that the synthetic pathway of Aureobasidium pullulans melanin and related genes have not yet been reported, and achieve the effect of improving the purification yield and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

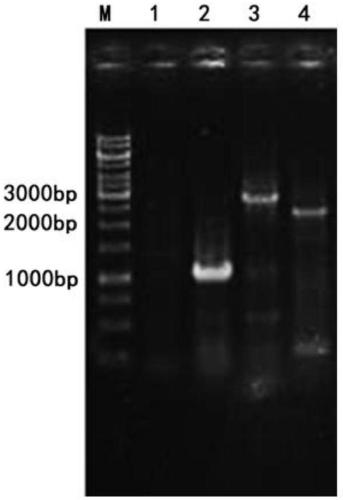

[0037] Example 1: Construction of Aureobasidium pullulans alb1 gene knockout mutant

[0038] (1) Synthesis of gene knockout fragments

[0039] A recombinant fragment containing alb1 left homology arm-hygromycin B resistance gene cassette-alb1 right homology arm was synthesized by whole gene synthesis method. The nucleotide sequence is shown in SEQ ID NO.4, and the recombinant fragment was connected to pUC18 The EcoRI site on the plasmid was used to construct the alb1 gene knockout plasmid.

[0040] The above recombinant fragments were synthesized by Sangon Bioengineering (Shanghai) Co., Ltd.

[0041] (2) Preparation of Aureobasidium pullulans As3.3984 electroporation competent

[0042] Pick a single colony of As3.3984 (purchased from the General Microbiology Center of China Microbiological Culture Collection Management Committee, the strain number is 3.3984) and inoculate it into 3mL YPD liquid medium, and culture it with shaking at 28°C for 48 hours; transfer 100μL culture to...

Embodiment 2

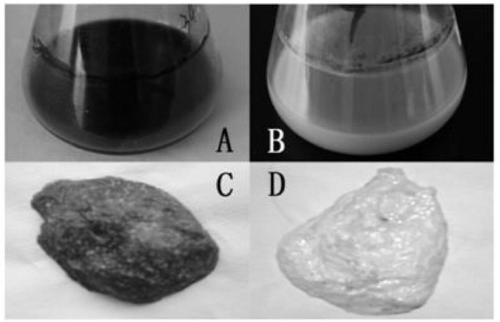

[0056] Embodiment 2: microbial polysaccharide fermentation and purification experiment

[0057] 1. Fermentation and purification of microbial polysaccharides:

[0058] (1) Strain fermentation: Aureobasidium pullulans originator As3.3984 and Aureobasidium pullulans mutant strain As3.3984Δalb1 obtained in Example 1 were respectively inoculated in the polysaccharide fermentation medium, and shake cultured at 28° C. for 72 hours.

[0059] Components of the above polysaccharide fermentation medium: sucrose 100.0g / L, yeast extract 2.0g / L, NaCl 1.0g / L, MgSO 4 .7H 2 O0.2g / L, K 2 HPO 4 5.0g / L, (NH 4 ) 2 SO 4 0.6g / L, pH6.5, sterilized at 115°C for 30 minutes.

[0060] (2) Precipitate crude polysaccharide:

[0061] The fermentation broth was centrifuged at 8000rpm for 10 minutes to collect the supernatant; 3 times the volume of industrial ethanol was added to the supernatant to precipitate the polysaccharide, the precipitate was collected by centrifugation at 3000rpm for 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com