High barrier film and composite film

A technology of high barrier and diaphragm, applied in the direction of synthetic resin layered products, electrical components, circuits, etc., can solve the problems of high barrier film's water and oxygen resistance performance reduction, barrier layer without protection, puncture, etc., to improve surface scratch resistance No damage to puncture resistance, high light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

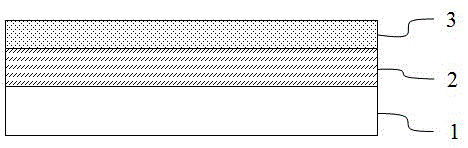

[0024] combine figure 1 As shown, the high barrier film of this embodiment includes: a substrate 1 , a barrier layer 2 and a hardened layer 3 from bottom to top.

[0025] Wherein, the substrate 1 in the present invention is a general-purpose transparent polymer substrate, and the material and thickness of the substrate are not particularly limited, and can be freely selected according to the purpose of use. Specifically, polyester film, nylon film, polypropylene film, transparent fluororesin, polyamide, fluorinated polyamide, polyimide, polyimide amide, polyether amide, epoxy resin, polycarbonate, Polyurethane resin, polyether ethyl ketone ester, alicyclic polysulfone, polyethersulfone, polyacrylate, polyethyl ether, fluorene ring-modified polycarbonate, alicyclic denatured polycarbonate, fluorene ring-modified polyester, cycloolefin copolymer things etc. Preferred are polyethylene terephthalate films (PET), nylon films (PA). In the present invention, the thickness of the s...

Embodiment 2

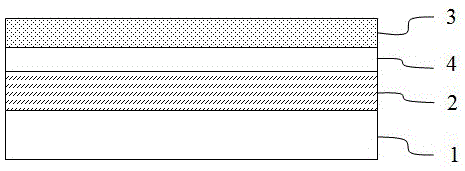

[0033] combine figure 1 As shown, the high barrier film of this embodiment comprises: a substrate 1 , a barrier layer 2 , a flexible organic layer 4 and a hardened layer 3 from bottom to top.

[0034] The substrate 1 , the barrier layer 2 and the hardened layer 3 in this embodiment are all the same as those in the first embodiment. The difference between this embodiment and the first embodiment is that a flexible organic layer 4 is provided between the barrier layer 2 and the hardened layer 3 .

[0035] Wherein, the flexible organic layer 4 is, relative to the hardening layer 3 , specifically a photocurable resin, such as urethane acrylate, polyester acrylate, epoxy acrylate, polyol acrylate, epoxy resin, and the like. Low-functionality monomers are preferred, and acrylate monomers with less than (or equal to) 2-functionality are preferred, such as 1,6-hexanediol diacrylate, neopentyl glycol diacrylate, etc., which can be used alone, Combinations are also possible. The phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com