Loaded type catalyst for eliminating formaldehyde at room temperature and preparation method of loaded type catalyst

A supported catalyst and formaldehyde elimination technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of infeasibility, weak effect, secondary pollution, etc., and increase the active specific surface area , good stability, combined with a solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

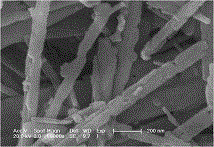

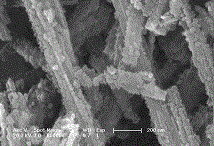

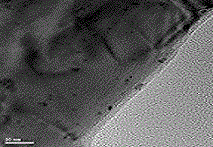

[0022] Dissolve 48 g of sodium hydroxide in 120 ml of water, add 0.6 g of titanium dioxide (P25) after cooling down and stir thoroughly for 3 hours to mix evenly, then transfer the evenly mixed solution to a 150 ml hydrothermal reaction kettle, and heat at 200 ºC Under reaction 72h. The obtained precipitate was washed with deionized water, and then dried to about pH=7. Then soak the obtained product in 0.1 mol / L hydrochloric acid solution and stir thoroughly for 24 hours, wash, filter, and dry the washing liquid in an oven at 80 ºC for 10 hours after the pH of the washing solution is about 7. Roasted in the furnace for 2 h to obtain titanium dioxide nanobelts, the SEM photos of the titanium dioxide nanobelts are as follows: figure 1 As shown, the titania nanoribbons are ribbon-shaped, with a width of 50 nm to 70 nm and a length of 5 μm to 30 μm.

[0023] The above unbaked samples were immersed in 0.02 M sulfuric acid solution and stirred thoroughly for 2 h until they were ev...

Embodiment 2

[0028] The acid-treated titanium dioxide nanobelts prepared by the same method as in Example 1 were used.

[0029] Add 0.6 g of the acid-treated titanium dioxide nanoribbons prepared above into a round-bottomed flask filled with 10 ml of deionized water, ultrasonically disperse for 20 minutes, and accurately measure 300 μl with a pipette gun at a concentration of 40 mg / ml (according to platinum element Concentration by mass meter, the same below) of chloroplatinic acid aqueous solution was added dropwise to the titanium dioxide solution, and after ultrasonic dispersion for 30 minutes, a mixed aqueous solution of 3.5 ml of sodium borohydride and sodium hydroxide was added to the above mixed solution with a pipette gun. In the solution, continue ultrasonication for 30 minutes to mix evenly, evaporate, dry in a blast drying oven at 100 ºC for 10 hours, and grind in an agate mortar to obtain a supported catalyst. The loading amount of platinum element in the prepared catalyst was ...

Embodiment 3

[0032] The acid-treated titanium dioxide nanobelts prepared by the same method as in Example 1 were used.

[0033] Add 0.6 g of the acid-treated titanium dioxide nanoribbons prepared above into a round-bottomed flask filled with 10 ml of deionized water, ultrasonically disperse for 20 minutes, and accurately measure 900 μl with a pipette gun at a concentration of 40 mg / ml (according to platinum element The concentration of the mass meter, the same below) of chloroplatinic acid aqueous solution was added dropwise in the titanium dioxide solution, and after ultrasonic dispersion for 30 minutes, the mixed aqueous solution of 3.5ml sodium borohydride and sodium hydroxide was added to the above mixed solution with a pipette gun. In the solution, continue ultrasonication for 30 minutes to mix evenly, evaporate, dry in a blast drying oven at 100 ºC for 10 hours, and grind in an agate mortar to obtain a supported catalyst. The loading amount of platinum element in the prepared catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com