Absorbing material with gelatin coupled on surface of polyurethane foam and preparation method and application of absorbing material

A polyurethane foam, adsorption material technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of slow washing speed, cumbersome process, high price, etc. Simplified, mildly conditioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: the preparation method of the adsorption material of this polyurethane foam surface diazo method coupling gelatin, concrete operation is as follows:

[0047] (1) Pretreatment of PUF: Cut the commercially available polyether PUF into a cuboid of 3×6×1cm, wash it with distilled water at 60°C for several times until the washing water is neutral, then dry it in vacuum at 60°C for 24 hours, and use fresh-keeping The film is tightly wrapped and placed in a desiccator for standby; the water absorption rate is measured W A is 1665.1%, tannin adsorption Q 2.7mg / g;

[0048] (2) Amino release of PUF: Add 10g of PUF cuboid with a size of about 3×3×0.2cm into the beaker, add 2 moL / L hydrochloric acid according to the volume-to-mass ratio of hydrochloric acid solution to PUF 50:1 (mL:g) Solution, seal the mouth of the beaker with plastic wrap, boil it in a boiling water bath for 4 hours, take out the product after the reaction and wash it repeatedly with distilled wa...

Embodiment 2

[0054] Embodiment 2: The preparation method of the adsorption material of this polyurethane foam surface diazo method coupling gelatin, concrete operation is: repeat embodiment 1, adjust step (2) hydrochloric acid solution concentration to be 1mol / L, gelatin aqueous solution in step (4) Adjust the concentration to 50g / L, gelatin aqueous solution and diazotization product PUF-N 2 + The volume mass mL:g is 50:1, and the irradiation time at 10cm under the ultraviolet lamp is adjusted to 50min / surface; the gelatin immobilization capacity of PUF-G is measured S 21.3mg / g, water absorption W A 2093.2%, tannin adsorption Q It was 25.7mg / g.

Embodiment 3

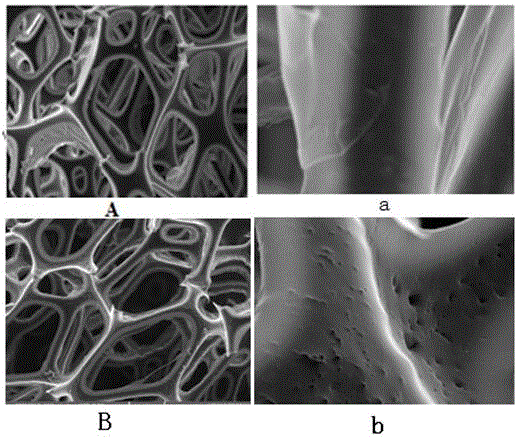

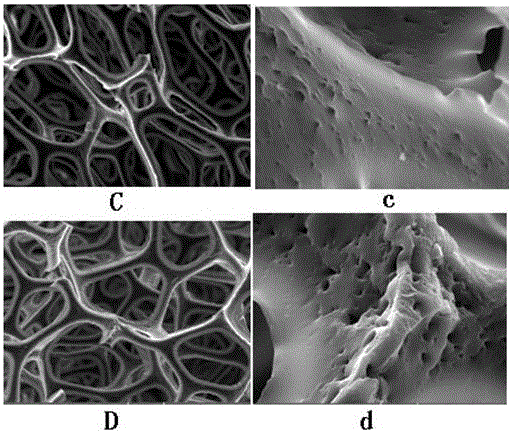

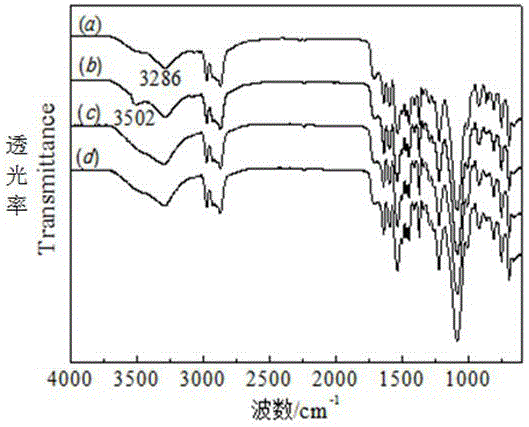

[0055] Embodiment 3: The preparation method of the adsorption material of this polyurethane foam surface diazo method coupling gelatin, concrete operation is: repeat embodiment 1, only the gelatin aqueous solution concentration in (4) is adjusted to 125g / L, gelatin aqueous solution and weight Nitriding product PUF-N 2 + The volume mass mL:g is 70:1, and the irradiation time is adjusted to 35min / surface; the water absorption rate of the PUF is measured W A is 1665.1%, tannin adsorption Q 1 It is 2.7mg / g; its SEM photo is shown in figure 1 A, a, ATR-FTIR spectrum see image 3 (a), XPS spectrum see Figure 4 A, surface C content is 62.33%, O content is 37.67%, N is not detected; its PUF-NH is detected 2 Amino content Am 0.7870mmol / g, water absorption W A 1727.5%, tannin adsorption Q 4.3mg / g, its SEM photo is shown in figure 1 B, b, ATR-FTIR spectrum see image 3 (b), XPS spectrum see Figure 4 B, the surface C content is 67.57%, the O content is 27.09%, and the N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fixed capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com