Preparation method of porcine epidemic diarrhea virus liposome diluent freeze-dried product

A technology for porcine epidemic diarrhea and freeze-dried products, which is applied in the directions of liposome delivery, virus/phage, biochemical equipment and methods, etc. The effect of increasing viral content and enhancing immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

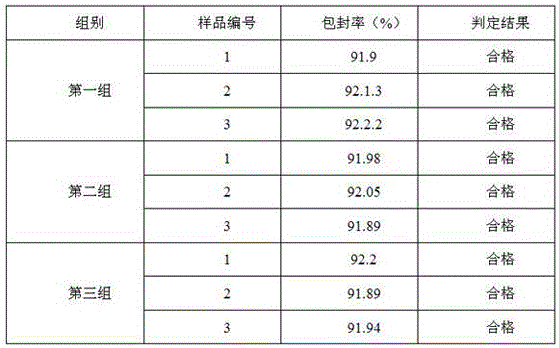

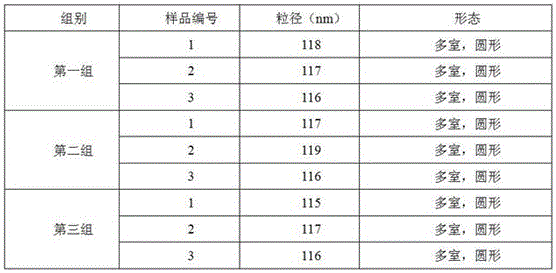

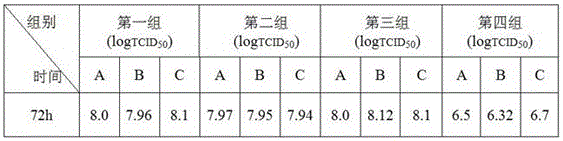

Embodiment 1

[0024] (1) Prepare phosphate buffer:

[0025] a. Weigh the following raw material components: sodium chloride 6g, potassium chloride 0.05g, disodium hydrogen phosphate 1g, potassium dihydrogen phosphate 0.05g, calcium chloride 0.05g and magnesium chloride hexahydrate (MgCl 2 ·6H 2 O) 0.05g, mix well and set aside;

[0026] b. Add 1000 mL of double-distilled water to the mixture of raw material components obtained in step a, and after fully dissolving, autoclave at 116°C for 30 minutes to obtain a phosphate buffer solution with pH=7.

[0027] (2) Extraction of Ophiopogon japonicus flavonoids:

[0028] Weigh 5g of Radix Ophiopogon japonicus, add 90% ethanol according to the ratio of solid to liquid 1:14, set the power of microwave oven to 900W, extract in microwave for 4min, reflux in water bath for 30min, and the obtained extract is filtered and evaporated to dryness to obtain Radix Ophiopogon japonicus flavonoids.

[0029] (3) Preparation of liposomes

[0030] A. Weigh ...

Embodiment 2

[0037] (1) Prepare phosphate buffer:

[0038] a. Weigh the following raw material components: sodium chloride 8g, potassium chloride 0.3g, disodium hydrogen phosphate 1.1g, potassium dihydrogen phosphate 0.25g, calcium chloride 0.1g and magnesium chloride hexahydrate (MgCl 2 ·6H 2 O) 0.13g, mix well and set aside;

[0039] b. Add 1000 mL of double-distilled water to the mixture of raw material components obtained in step a, and after fully dissolving, autoclave at 116°C for 30 minutes to obtain a phosphate buffer solution with pH=7.

[0040] (2) Extraction of Ophiopogon japonicus flavonoids:

[0041] Weigh 5g of Radix Ophiopogon japonicus, add 90% ethanol according to the ratio of solid to liquid 1:14, set the power of microwave oven to 900W, extract in microwave for 4min, reflux in water bath for 30min, and the obtained extract is filtered and evaporated to dryness to obtain Radix Ophiopogon japonicus flavonoids.

[0042] (3) Preparation of liposomes

[0043] A. Weigh ...

Embodiment 3

[0050] (1) Prepare phosphate buffer:

[0051] a. Weigh the following raw material components: sodium chloride 10g, potassium chloride 0.5g, disodium hydrogen phosphate 1.2g, potassium dihydrogen phosphate 0.5g, calcium chloride 0.2g and magnesium chloride hexahydrate (MgCl 2 ·6H 2 O) 0.2g, mix well and set aside;

[0052] b. Add 1000 mL of double-distilled water to the mixture of raw material components obtained in step a, and after fully dissolving, autoclave at 116°C for 30 minutes to obtain a phosphate buffer solution with pH=7.

[0053] (2) Extraction of Ophiopogon japonicus flavonoids:

[0054] Weigh 5g of Radix Ophiopogon japonicus, add 90% ethanol according to the ratio of solid to liquid 1:14, set the power of microwave oven to 900W, extract in microwave for 4min, reflux in water bath for 30min, and the obtained extract is filtered and evaporated to dryness to obtain Radix Ophiopogon japonicus flavonoids.

[0055] (3) Preparation of liposomes

[0056] A. Weigh 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com