N, N-dimethyl dodecyl terminal quaternization modified silicone oil, and preparation method and application thereof

A technology of dimethyldodecyl and quaternary ammonium modification, which is applied in the fields of biochemical fiber treatment, textile and papermaking, and improved hand-feeling fibers, etc. Stability and other issues, to achieve the effect of good whiteness and water absorption, regular structure, and improved softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

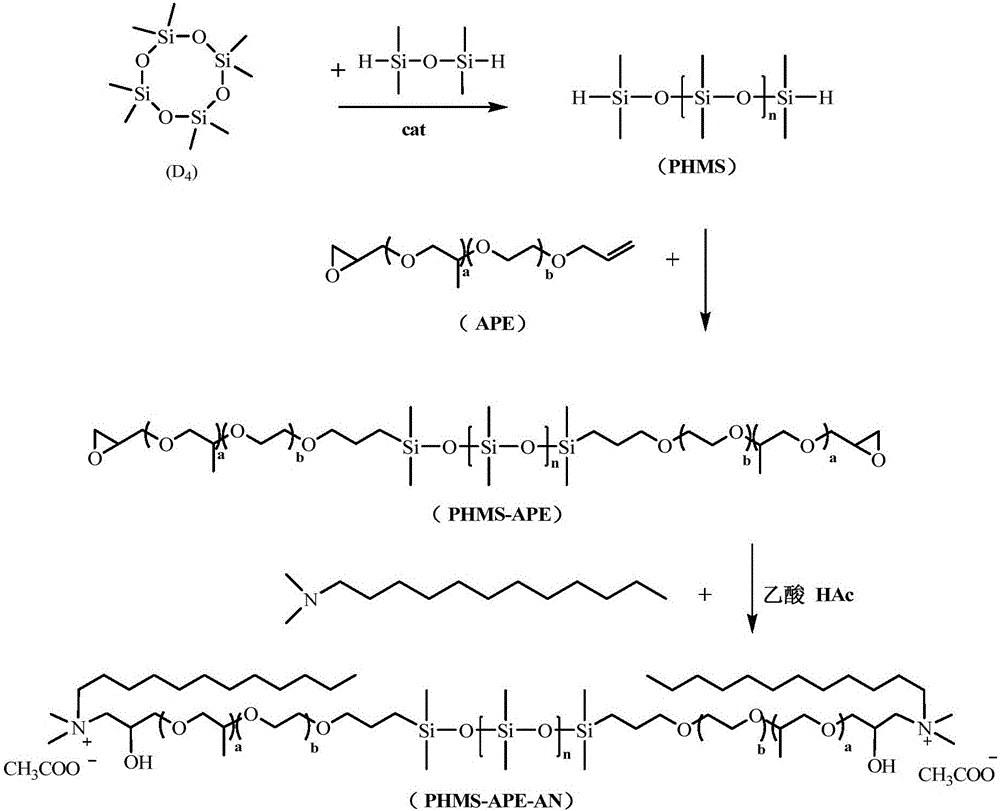

[0055] Octamethylcyclotetrasiloxane (D 4 ), hydrogen-containing double-heads, and catalyst acid clay solids were added into a three-necked flask equipped with a magnetic stirrer, a thermometer, and a condenser at a mass ratio of 100:24.54:2.5, and stirred and heated to 65°C for 24 hours under a nitrogen atmosphere. After the end, the viscosity of the system increased, the catalyst was removed by filtration, and the low boilers were distilled off under reduced pressure at 100°C to obtain a colorless and transparent product, which was a terminal hydrogen-containing silicone oil with a molar mass of about 680 g / mol, marked as PHMS1.

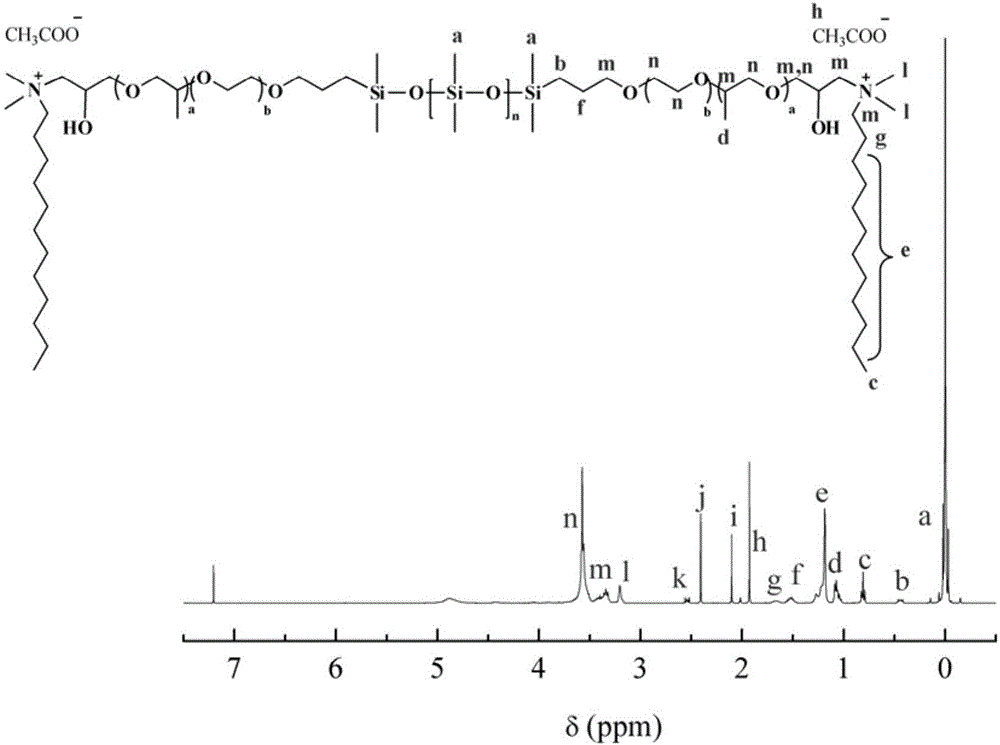

[0056] Put terminal hydrogen-containing silicone oil PHMS1 and allyl polyoxyethylene polyoxypropylene glycidyl ether (molar mass 700g / mol, marked as APE, industrial product, presented by Zhejiang Queping Textile Chemical Co., Ltd.) at a molar ratio of 1:2 Add it into the flask, under nitrogen atmosphere, add 50ppm of chloroplatinic acid (calculated ...

Embodiment 2

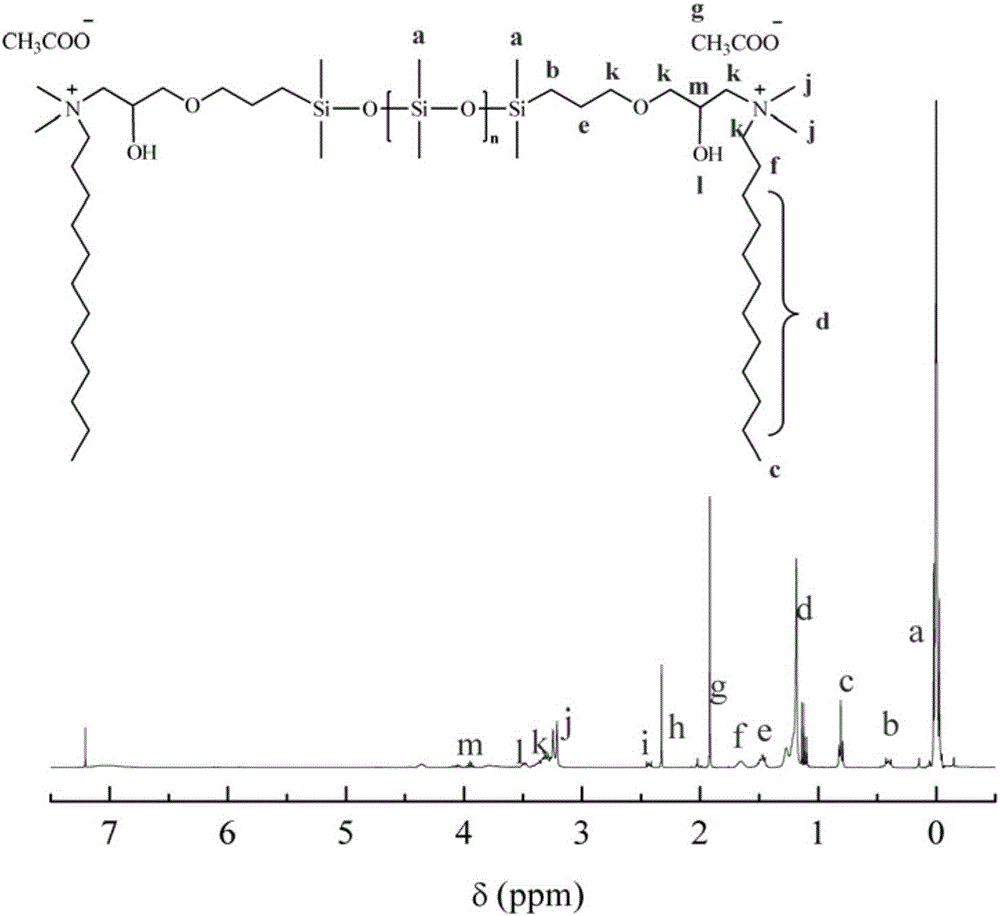

[0059] Octamethylcyclotetrasiloxane (D 4 ), hydrogen-containing double-heads, and catalyst acid clay solids were added into a three-necked flask equipped with a magnetic stirrer, a thermometer, and a condenser at a mass ratio of 100:3.56:2.1, and stirred and heated to 65°C for 24 hours under nitrogen atmosphere. After the end, the viscosity of the system increased, the catalyst was removed by filtration, and the low boilers were distilled off under reduced pressure at 100°C to obtain a colorless and transparent product, which was a terminal hydrogen-containing silicone oil with a molar mass of about 3900 g / mol, marked as PHMS2.

[0060] Add terminal hydrogen-containing silicone oil PHMS2 and allyl polyoxyethylene polyoxypropylene glycidyl ether into the flask at a molar ratio of 1:2, add 50ppm of chloroplatinic acid catalyst under nitrogen atmosphere, stir and heat up to 80°C, After reacting for 8 hours, a colorless to light yellow transparent product was obtained, namely epox...

Embodiment 3

[0063] Octamethylcyclotetrasiloxane (D 4 ), hydrogen-containing double-capped heads, and catalyst concentrated sulfuric acid were added into a three-necked flask equipped with a magnetic stirrer, a thermometer, and a condenser at a mass ratio of 100:1.4:2, and stirred and heated to 65°C for 24 hours under a nitrogen atmosphere. After the end, the viscosity of the system becomes larger, add sodium bicarbonate to neutralize the concentrated sulfuric acid, stir for a period of time, then filter to remove the solid, and finally remove the low boilers by distillation under reduced pressure at 100°C to obtain a colorless and transparent product with a molar mass of 9700g / The hydrogen-containing silicone oil at the end of about mol is marked as PHMS3.

[0064] Add terminal hydrogen-containing silicone oil PHMS3 and allyl polyoxyethylene polyoxypropylene glycidyl ether into the flask at a molar ratio of 1:2, add 50 ppm of chloroplatinic acid catalyst under nitrogen atmosphere, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com