A kind of high-efficiency preparation method of boron nitride nanosheet and its organic dispersion

A boron nitride, nanosheet technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low preparation efficiency, complex transfer technology, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

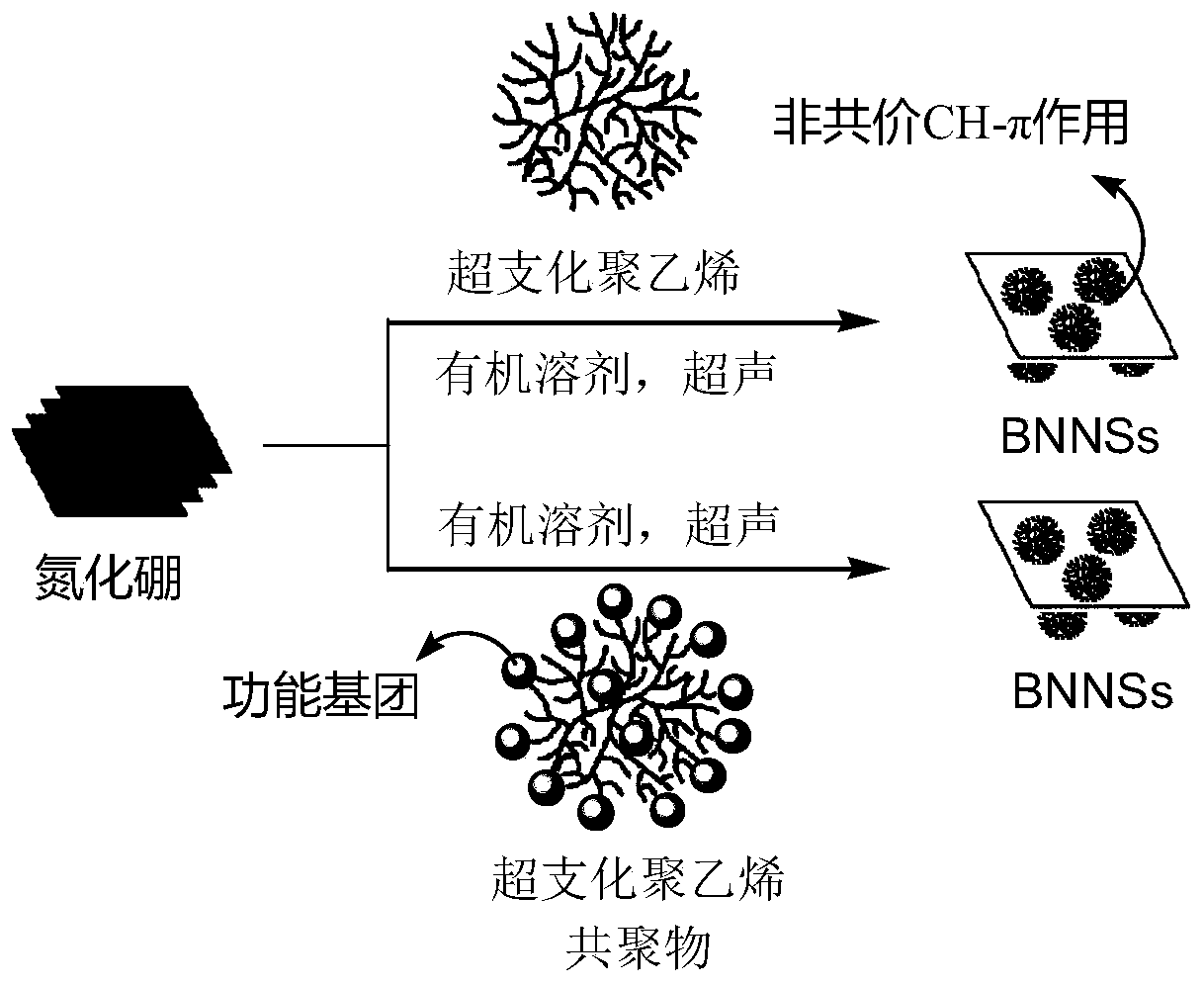

AI Technical Summary

Problems solved by technology

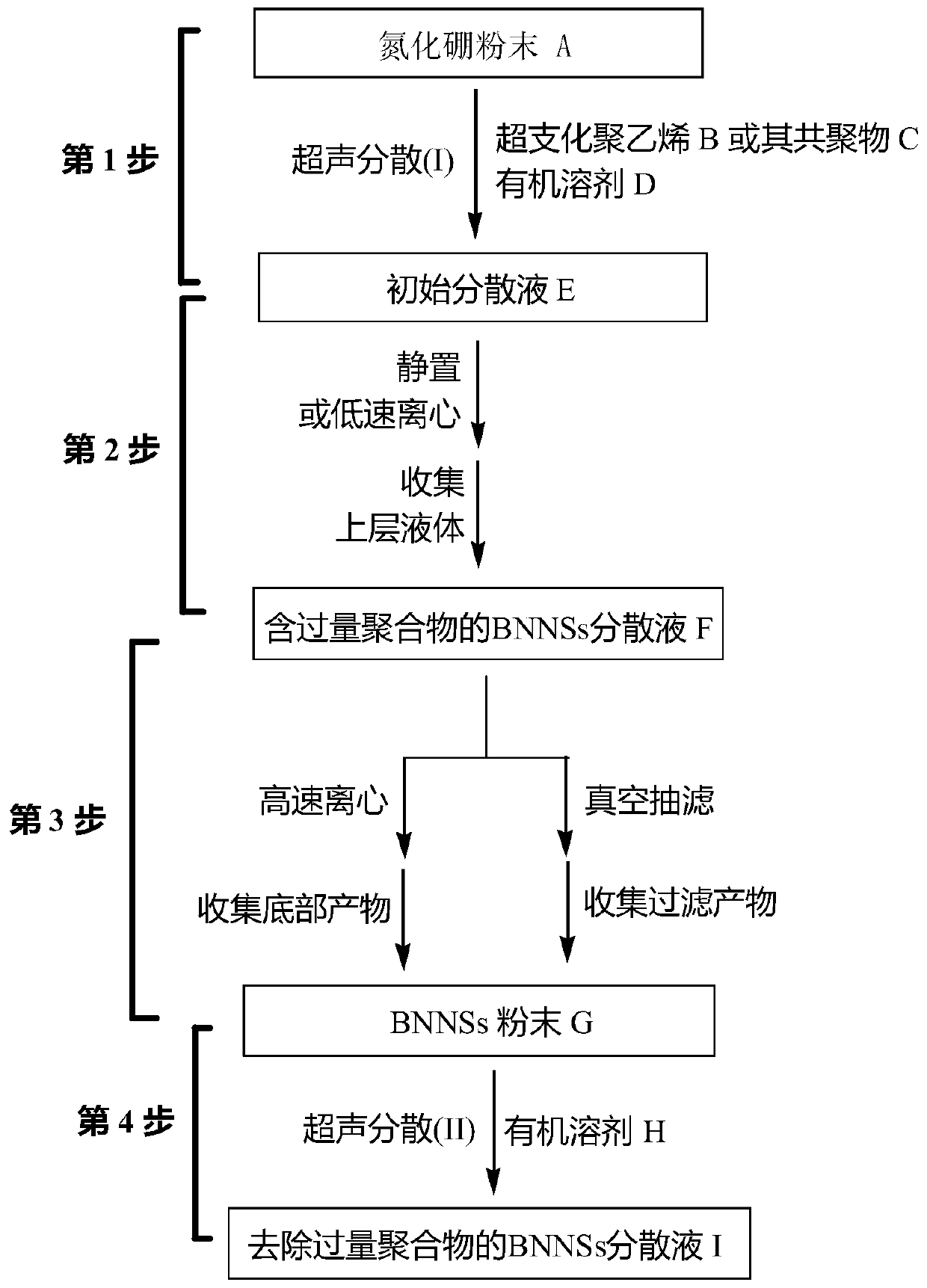

Method used

Image

Examples

Embodiment 1、2

[0080] Embodiment 1, 2, comparative example 1, 2

[0081] 1. Sample preparation

[0082] (1) The preparation of embodiment 1 sample is carried out as follows:

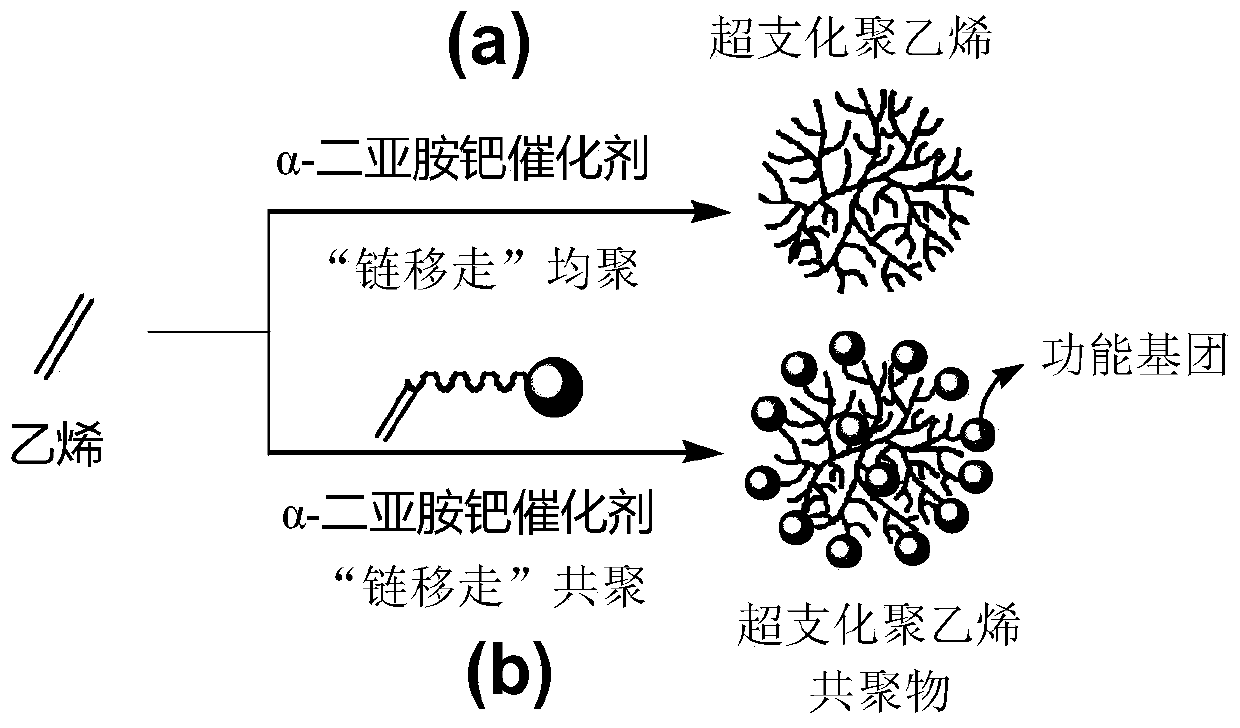

[0083] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the temperature of the system at 35 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0 g / L), at a constant temperature of 35° C. and ethylene pressure of 0.1 MPa, the polymerization was continued for 24 h by stirring. After the reaction, the obtained product was poured into 50 mL of methanol containing 1 wt% hydrochloric acid, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hydrochloric acid were added, stirred at room temperature for 1 h to dissol...

Embodiment 3, comparative example 3、4、5

[0098] 1. Sample preparation

[0099] (1) The preparation of embodiment 3 sample is carried out as follows:

[0100] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the system temperature at 15 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0g / L) and 2.50g methyl acrylate (MA, 0.58mol / L) were injected into the reaction flask, and the polymerization was continued for 24h by stirring at a constant temperature of 15°C and ethylene pressure of 0.1MPa . After the reaction, the resulting product was poured into 50 mL of acidified methanol with a concentration of 1 wt%, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hydrochloric acid were added, stirred at room te...

Embodiment 4

[0125] Embodiment 4, comparative example 6

[0126] 1. Sample preparation

[0127] (1) The preparation of embodiment 4 sample is carried out as follows:

[0128] Step 1: Under the protection of ethylene, add 50.0 mL of anhydrous dichloromethane to a Schlenk double-layer reaction flask with a capacity of 250 mL, keep the system temperature at 15 ° C by stirring, and then add 0.10 g of acetonitrile α-diethylene oxide Amine palladium catalyst (1, concentration 2.0g / L) and 4.50g butyl acrylate (BA, 0.70mol / L) were injected into the reaction flask, and the polymerization was continued for 24h by stirring at a constant temperature of 15°C and ethylene pressure of 0.1MPa . After the reaction, the resulting product was poured into 50 mL of acidified methanol with a concentration of 1 wt%, and stirred to terminate the polymerization. After further drying the solvent, the obtained product was dissolved with an appropriate amount of THF, and a small amount of hydrogen peroxide and hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com