Fermentation promoter for improving output of gentamycin C1a, and adding method thereof

A fermentation accelerator, the technology of gentamicin, applied in the field of fermentation engineering, can solve the problems of not being able to change the balance point of the enzyme reaction in the organism, increasing the risk of converting to primary metabolism, and having no clear and complete explanation, so as to facilitate fermentation Effects of production, change of rheological properties, increase of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of described fermentation accelerator: at first be to join the D-xylose of corresponding quality, N-acetylglucosamine, ammonium ferrous sulfate, betaine and 2-deoxystreptamine into deionized water, then place 45 ℃, 150rpm magnetic heating stirrer until it is completely dissolved, and then filtered through a microporous filter with a pore size of 0.22 µm to obtain a sterile fermentation accelerator for future use.

[0017] Warm the prepared fermentation accelerator in a water bath at 30-36°C for 15-30 minutes, then add it to the fermentation medium at a ratio of 0.001-0.005% of the volume of the fermentation medium to directly participate in the fermentation process; or mix the prepared According to the ratio of 0.001-0.005% of the feed volume, the fermentation accelerator is added to the feed, and is added to the fermentation medium to participate in fermentation along with the feed; or the above two methods are used in combination, and the ferment...

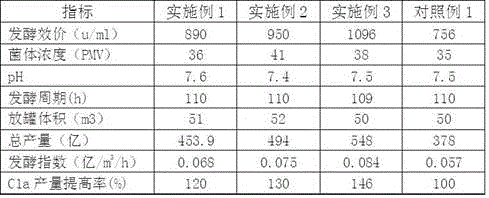

Embodiment 1

[0019] The fermentative production method of embodiment 1 gentamicin Cla

[0020] The production of gentamicin C1a usually adopts the form of graded fermentation. The gentamicin C1a producing bacterium Micromonospora is prepared by spores and mycelia cultured in shake flasks, and then put into the seed tank. Connect to the fermenter for cultivation, during the cultivation process, feed materials according to the specific situation, the specific operation of the fermentation process is as follows:

[0021] 1. Configuration of culture medium

[0022] Incline medium: K 2 HPO 4 0.01%, NaCl 0.05%, MgSO 4 0.05%, glucose 0.1%, corn flour 2% and agar powder 2%, the rest is water, and the percentages are mass percentages;

[0023] Mycelium medium: K 2 HPO 4 0.01%, NaCl 0.05%, MgSO 4 0.05%, glucose 1% and corn flour 2%, the rest is water, and the percentages are mass percentages;

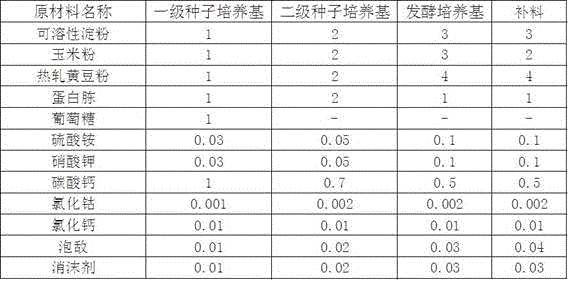

[0024] First-level seed culture medium: the feeding configuration is carried out according to ...

Embodiment 2

[0042] Add the fermentation accelerator whose volume percentage is 0.002% in the feeding material, but do not add it in the fermentation medium. Other specific fermentation process techniques (medium configuration, spore culture, primary seed cultivation, secondary seed cultivation, fermentation cultivation and feeding control) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fermentation titer | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com