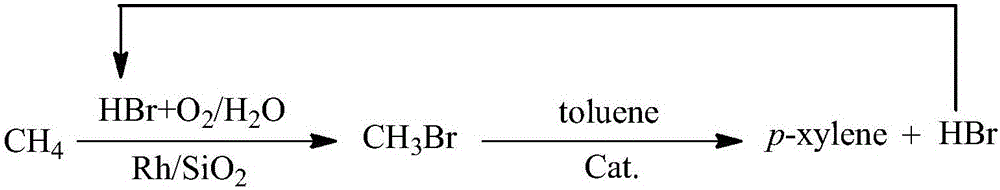

Preparation method of micron-sized HZSM-5 molecular sieve and application of micron-sized HZSM-5 molecular sieve

A molecular sieve, micron-scale technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon production from halogen-containing organic compounds, etc., can solve the problems such as the inconspicuous advantage of xylene diffusion, achieve simple and easy preparation process, and improve para-position Selectivity, catalytic activity and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

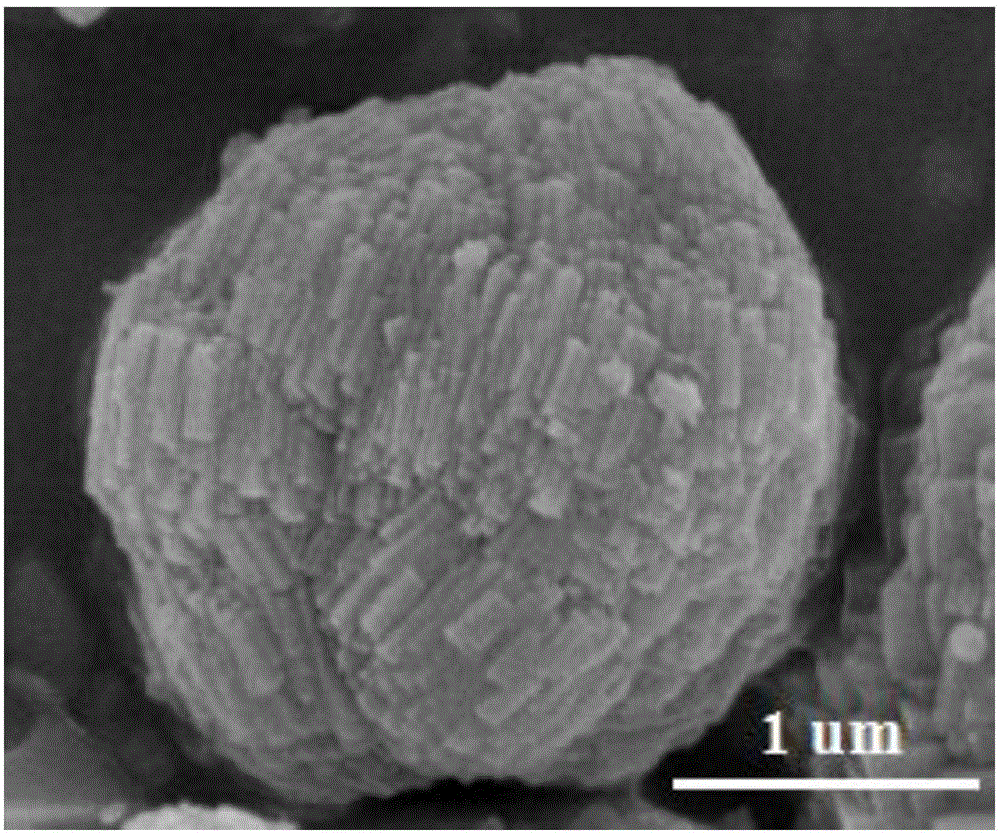

Embodiment 1

[0028] According to the molar ratio of material SiO 2 :Al 2 o 3 :TPAOH:TEA:NaOH:H 2 The ratio of O=100:0.67:30:10:16.5:3800, with 20.03g silica sol (30wt.%), 0.446g aluminum sulfate, 24.402g tetrapropyl ammonium hydroxide (25wt.%), 1.012g triethyl Amine, 0.660g sodium hydroxide and water, mix well, statically crystallize at 180°C for 24h, cool, centrifuge, wash with water until neutral, dry overnight, then place in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Molecular sieve Na-ZSM-5; ion exchange with 1mol / L ammonium nitrate solution at 80°C for 3h, repeat once, wash with water, dry overnight, put in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Si / Al =75 HZSM-5 molecular sieve A.

[0029] Molecular sieve catalyzed methyl bromide toluene to prepare p-xylene reaction is carried out in a miniature fixed bed quartz reactor, take 1g of the above catalyst, nitrogen carrier gas flow rate 10...

Embodiment 2

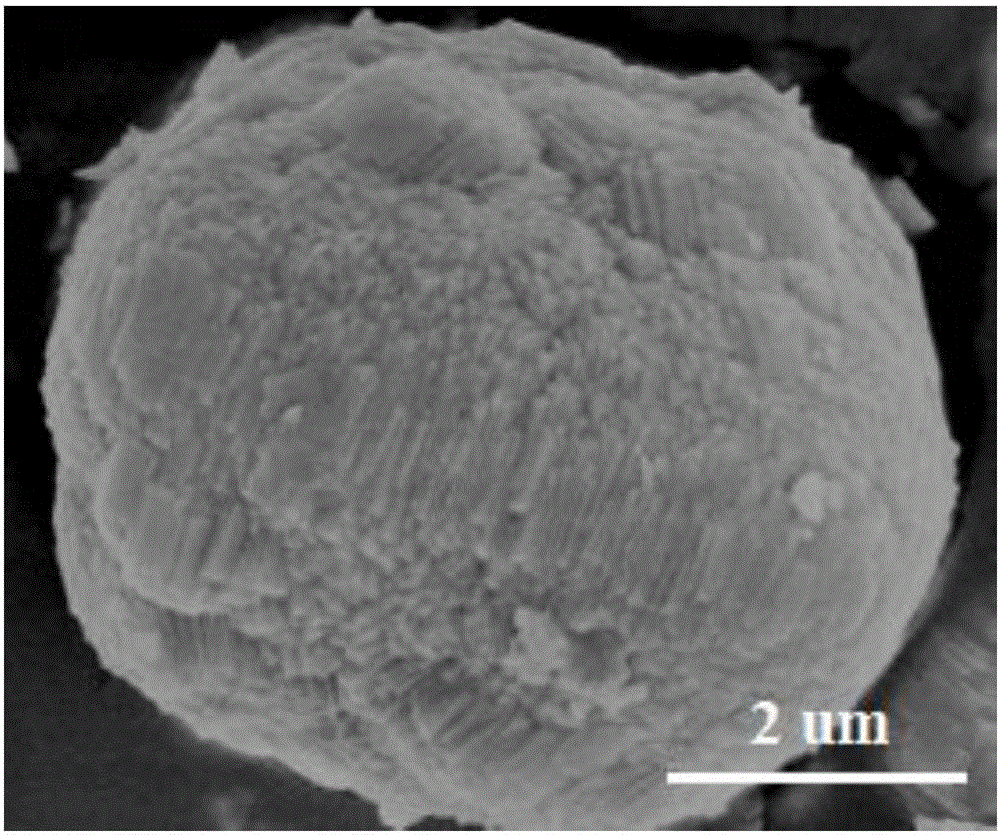

[0031] According to the molar ratio of material SiO 2 :Al 2 o 3 :TPAOH:TEA:NaOH:H 2 The ratio of O=100:0.67:20:20:16.5:3800, with 20.03g silica sol (30wt.%), 0.446g aluminum sulfate, 16.268g tetrapropyl ammonium hydroxide (25wt.%), 2.024g triethyl Amine, 0.660g sodium hydroxide and water, mix well, statically crystallize at 180°C for 24h, cool, centrifuge, wash with water until neutral, dry overnight, then place in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Molecular sieve Na-ZSM-5; ion exchange with 1mol / L ammonium nitrate solution at 80°C for 3h, repeat once, wash with water, dry overnight, put in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Si / Al =75 HZSM-5 Molecular Sieve B.

[0032] Molecular sieve catalyzed methyl bromide toluene to prepare p-xylene reaction is carried out in a miniature fixed bed quartz reactor, take 1g of the above catalyst, nitrogen carrier gas flow rate 10...

Embodiment 3

[0034] According to the molar ratio of material SiO 2 :Al 2 o 3 :TPAOH:TEA:NaOH:H 2 The ratio of O=100:0.67:10:30:16.5:3800, with 20.03g silica sol (30wt.%), 0.446g aluminum sulfate, 8.134g tetrapropyl ammonium hydroxide (25wt.%), 3.036g triethyl Amine, 0.660g sodium hydroxide and water, mix well, statically crystallize at 180°C for 24h, cool, centrifuge, wash with water until neutral, dry overnight, then place in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Molecular sieve Na-ZSM-5; ion exchange with 1mol / L ammonium nitrate solution at 80°C for 3h, repeat once, wash with water, dry overnight, put in a muffle furnace and gradually raise the temperature to 550°C, and roast for 5h to obtain Si / Al =75 HZSM-5 molecular sieve C.

[0035] Molecular sieve catalyzed methyl bromide toluene to prepare p-xylene reaction is carried out in a miniature fixed bed quartz reactor, take 1g of the above catalyst, nitrogen carrier gas flow rate 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com