Method for separating and purifying vitamin K2 in bacillus subtilis natto

A technology for separation and purification of Bacillus natto is applied in the field of bioengineering to achieve the effects of high biological activity, simple process operation and convenient industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

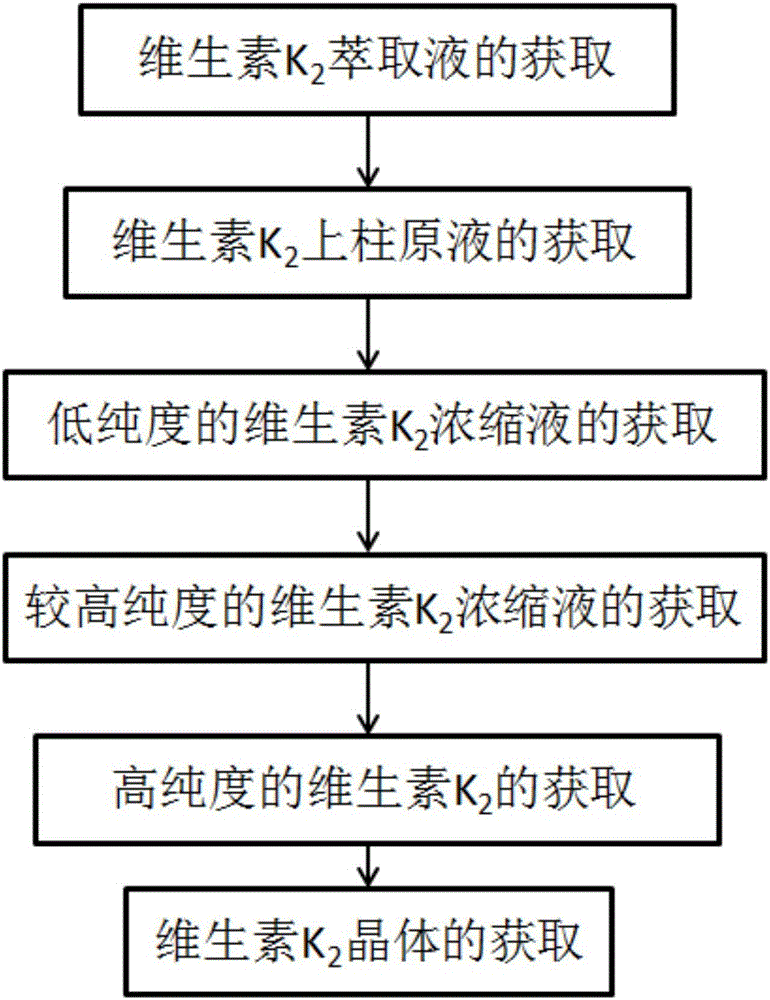

[0041] Vitamin K isolated and purified from Bacillus natto 2 method, such as figure 1 shown, including the following steps:

[0042] (1) Vitamin K 2 Extraction

[0043] Taking Bacillus natto fermentation broth as vitamin K 2 Extract the original solution, centrifuge to obtain the bacteria, after drying, use ethanol to extract to obtain vitamin K 2 Extraction solution; the extraction method is static extraction, the extraction time is 20min, and the extraction frequency is 1 time.

[0044] (2) Vitamin K 2 Obtaining the stock solution on the column

[0045] Vitamin K 2 The extract is passed through a membrane separation device (membrane pore size ≤ 0.45 μm) to remove insoluble impurities, and the obtained vitamin K 2 The filtrate was evaporated to dryness under reduced pressure, and then redissolved with methanol to obtain vitamin K 2 Stock solution on the column;

[0046] (3) Low-purity vitamin K 2 Acquisition of Concentrate

[0047] Vitamin K 2 The stock solution ...

Embodiment 2

[0057] Vitamin K isolated and purified from Bacillus natto 2 method, such as figure 1 shown, including the following steps:

[0058] (1) Vitamin K 2 Extraction

[0059] Taking Bacillus natto fermentation broth as vitamin K 2 Extract the original solution, centrifuge to obtain the bacteria, after drying, extract with toluene to obtain vitamin K 2 Extraction solution; the extraction method is static extraction, the extraction time is 60min, and the extraction frequency is 3 times.

[0060] (2) Vitamin K 2 Obtaining the stock solution on the column

[0061] Vitamin K 2 The extract is passed through a membrane separation device (membrane pore size ≤ 0.45 μm) to remove insoluble impurities, and the obtained vitamin K 2 The filtrate was evaporated to dryness under reduced pressure, then redissolved with acetone to obtain vitamin K 2 Stock solution on the column;

[0062] (3) Low-purity vitamin K 2 Acquisition of Concentrate

[0063] Vitamin K 2 The stock solution on the...

Embodiment 3

[0073] Vitamin K isolated and purified from Bacillus natto 2 method, such as figure 1 shown, including the following steps:

[0074] (1) Vitamin K 2 Extraction

[0075] Taking Bacillus natto fermentation liquid (composition: soybean powder 65g / L, corn flour 60g / L, peptone 50g / L, fermentation period: 7-9 days) as vitamin K 2 Extract the original solution, centrifuge to obtain the bacteria, after drying, extract according to the following steps:

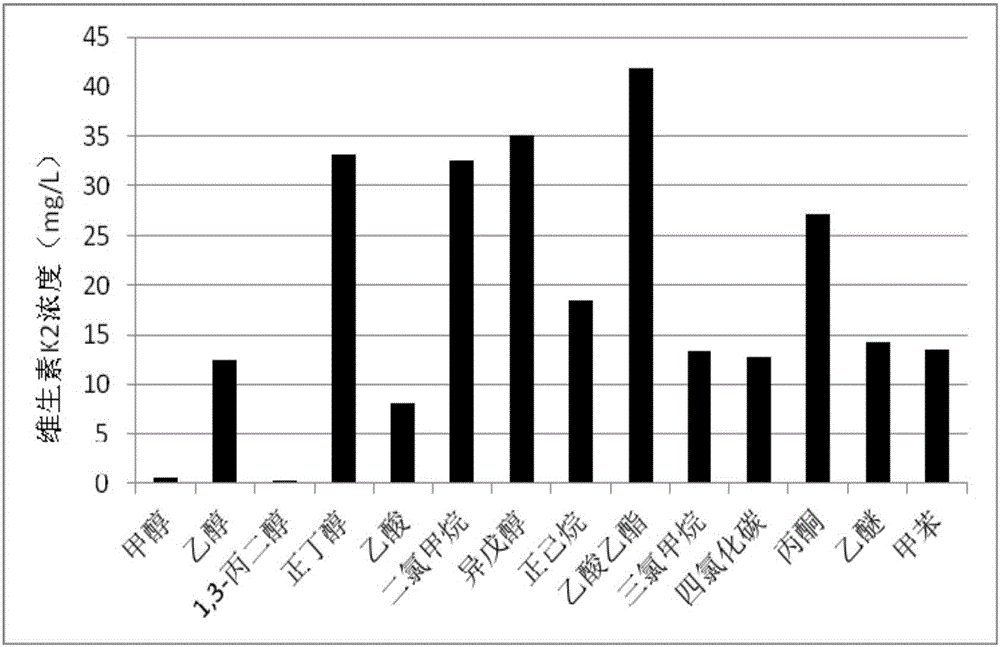

[0076] ① Weigh several portions of 1.0g of dry bacteria into a 50ml centrifuge tube, add 5ml of different organic solvents to stand for extraction for 50min, extract twice, and make 3 parallel samples; the different organic solvents are methanol, ethanol, 1,3 propylene glycol, n-butanol, acetic acid, dichloromethane, isoamyl alcohol, n-hexane, ethyl acetate, chloroform, carbon tetrachloride, acetone, ether, toluene;

[0077] ② Dilute the obtained extract to 5ml to obtain the test solution;

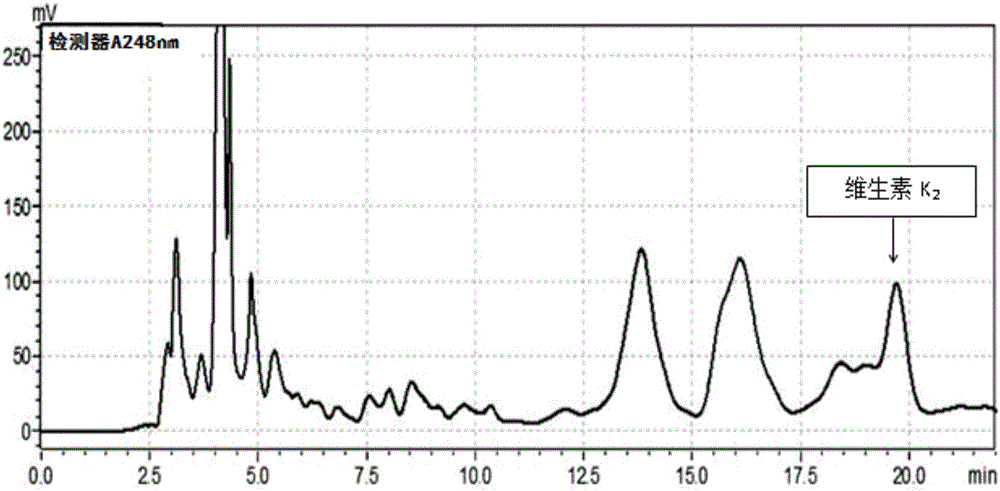

[0078] ③Use the HPLC method (mobile ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com