Polyurethane environmental-protection spraying material and preparation method thereof

A polyurethane, environmentally friendly technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of large rebounding force on the working surface, large operation dust, secondary environmental pollution, etc., and reach the rebound range. Small, excellent resilience, low dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

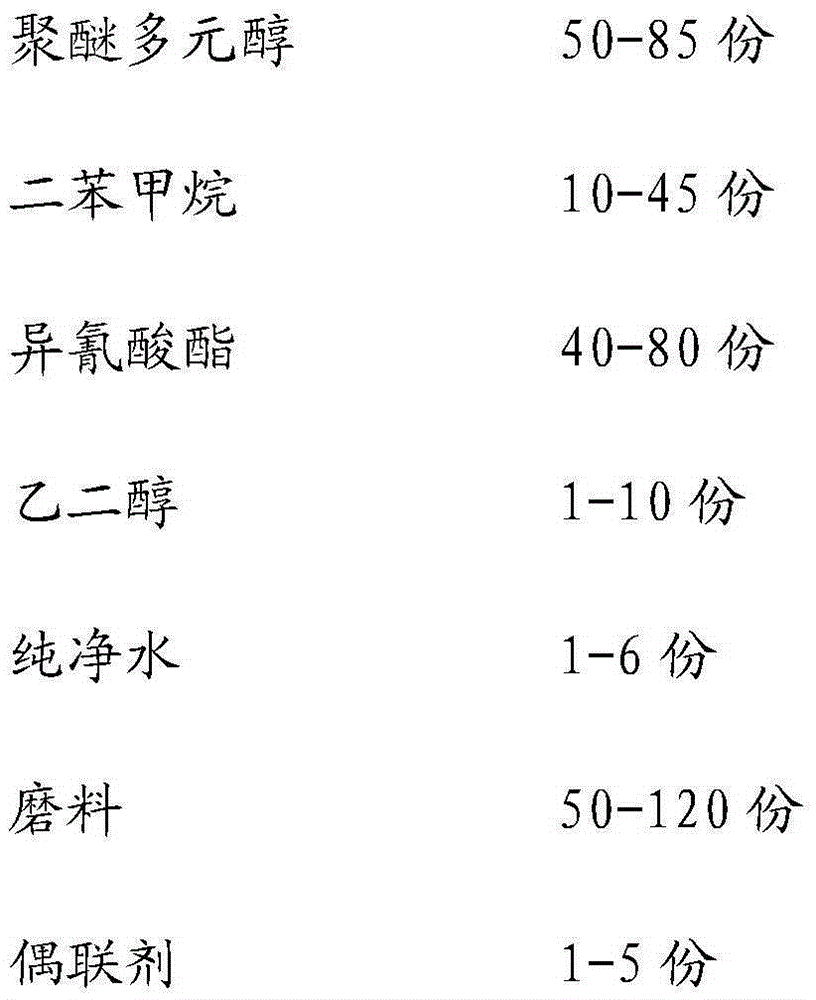

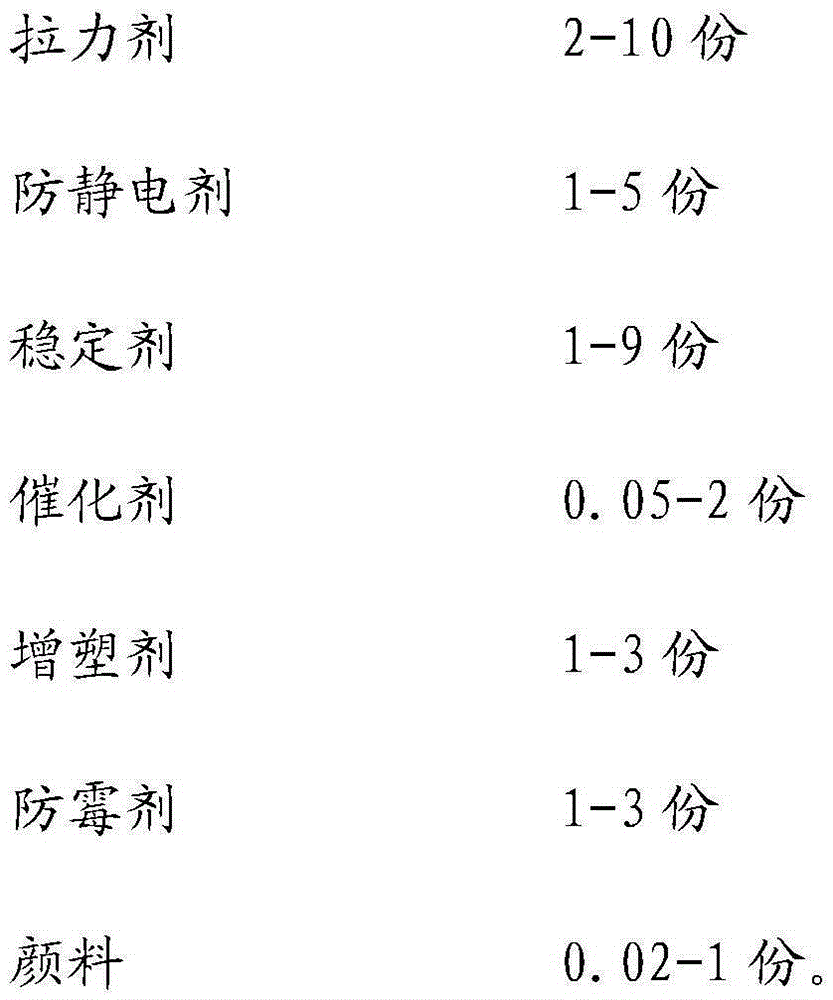

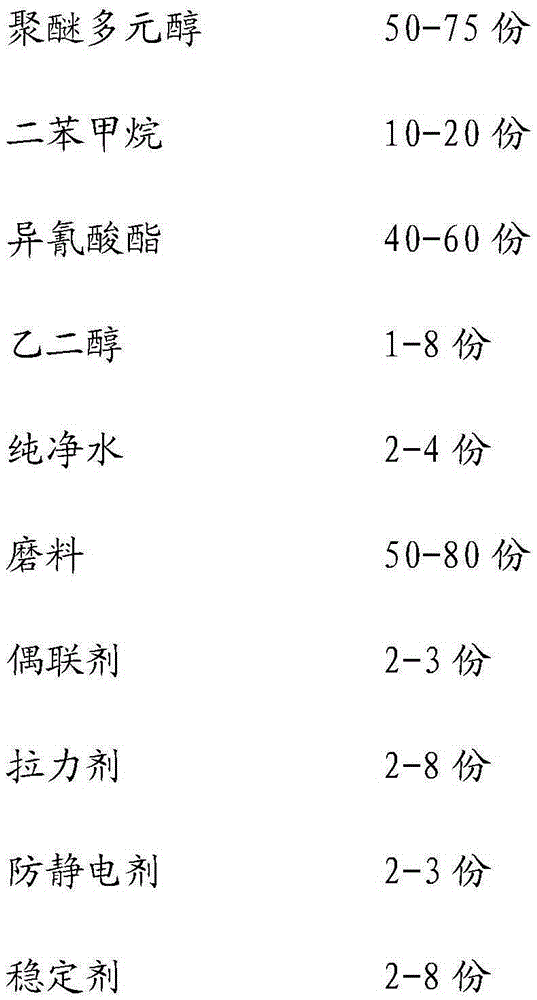

[0048] Next, weigh the raw materials according to the proportions in Table 1, and prepare according to the steps of the following preparation method. The difference is that the added raw material proportions are different, and the products are prepared. See Table 1-3 for details:

[0049] Wherein the polyether polyol described in Table 1-3 is the polyether polyol produced by Wanhua Chemical Group Co., Ltd. The abrasive is a mixture of glass beads and fine sand mixed with glass sand and fine sand at a weight ratio of 1:4. The average particle size of the abrasive is 50-200um; the coupling agent is γ-aminopropyltriethoxysilane (KH650), and the tension agent is the tension agent produced by Taian Quanxin Chemical Technology Co., Ltd., which is the model xq-124 agent. The antistatic agent is sodium alkyl sulfonate, the stabilizer is calcium / zinc composite stabilizer, the catalyst is stannous octoate T-9, the plasticizer is di-n-octyl phthalate (DNOP), and the fungicide is phenol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com