Carbon layer-coated chromium-doped strontium titanate/titanium dioxide nanotube photoelectrode and its preparation and application

A titanium dioxide and chromium doping technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of low solar energy utilization and conversion rate, reduced photoelectric catalytic activity, poor stability, etc., and achieve excellent visible light absorption characteristics, increase The effect of large absorption and conversion efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a carbon layer-coated chromium-doped strontium titanate / titanium dioxide nanotube heterostructure photoelectrode, comprising the following steps:

[0041] (1) The titanium plate was polished with 100#, 300# and 800# sandpaper in turn until its surface was smooth and flat; then it was ultrasonically cleaned with double distilled water and ethanol solution for 10 min, and then its surface was blown dry with nitrogen. At room temperature, in the traditional two-electrode system, the platinum sheet and the titanium sheet are used as the cathode and the anode respectively, and the electrode spacing is 1 cm; multi-step electrochemical anodization is performed when the applied cell voltage is 60V. The electrochemical anodizing electrolyte solution is: 0.3wt% NH 4 F and 2.0vol%H 2 O solution in ethylene glycol. After anodization, the anodized product was ultrasonically treated with twice distilled water for 1 min, and then the crystallized anodized prod...

Embodiment 2

[0045] At room temperature, the traditional three-electrode system was used to perform photoelectrochemical performance tests on a CHI660c electrochemical workstation, and the carbon layer-coated chromium-doped strontium titanate / titanium dioxide nanotube heterostructure photoelectrode prepared in Example 1 was used as the photoanode , a saturated calomel electrode (SCE) and a Pt sheet were used as reference and counter electrodes, respectively. A 0.5mol / L KOH solution of 0.1mol / L glucose is used as the electrolyte. The test results of the ampere i-t curve show that the photocurrent density of the carbon-coated chromium-doped strontium titanate / titanium dioxide nanotube heterostructure photoelectrode is as high as 0.44mA / cm 2 . Compared with the oxidation photocurrent density value of pure water oxidation at its surface of 0.28mA / cm 2 , the results further show that the biomass derivative glucose is more likely to undergo oxidation reaction on the surface of the photoelectro...

Embodiment 3

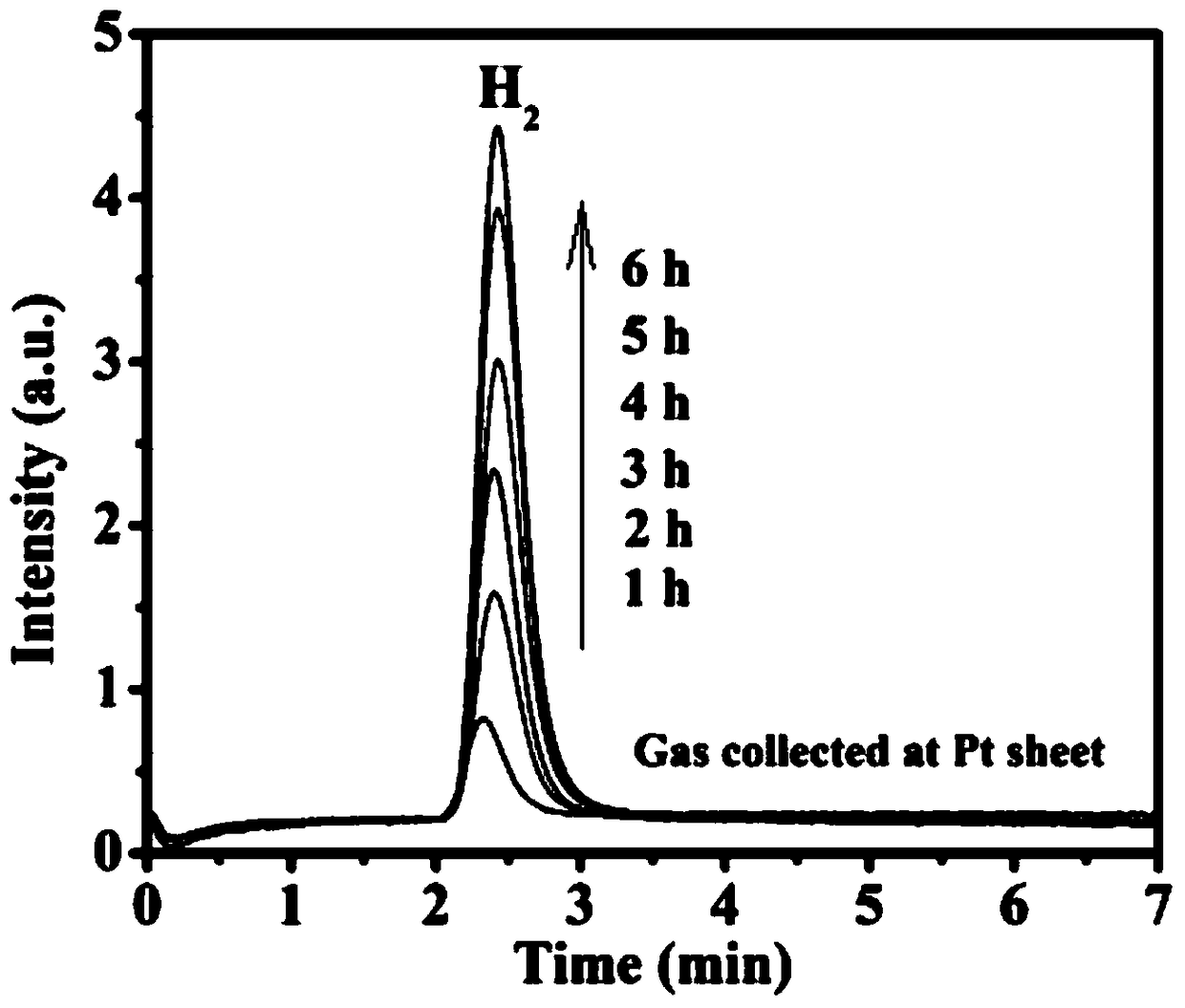

[0047] In a sealed gas circulation system equipped with a self-made three-electrode reactor and a vacuum circuit, the carbon layer-coated chromium-doped strontium titanate / titanium dioxide nanotube heterostructure photoelectrode prepared in Example 1 was used as the photoanode, and the platinum sheet was used as the photoanode. The cathode and saturated calomel electrode (SCE) are used as reference electrodes, and the electrolyte solution is: 0.5mol / L KOH electrolyte solution containing 0.1mol / L glucose. A 300W short-arc Xe lamp was equipped with a visible light filter as a visible light source and a -0.3V (vs. SCE) bias was applied at the Pt cathode. Finally, the collected gas was qualitatively and quantitatively determined by on-line gas chromatography (GC) equipped with a thermal conductivity sensor (TCD). Such as figure 2 as shown ( figure 2 , the curves are 1h, 2h, 3h, 4h, 5h, 6h from bottom to top), and the hydrogen production at the Pt cathode shows a gradual increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com