Composite tissue repair patch and preparation method and application thereof

A composite tissue and patch technology, which is applied in tissue regeneration, pharmaceutical formulations, prostheses, etc., can solve the problems of small porosity of composite patches and complex composite processes, and achieves a simple method, promotes regeneration, and is not easy to delaminate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

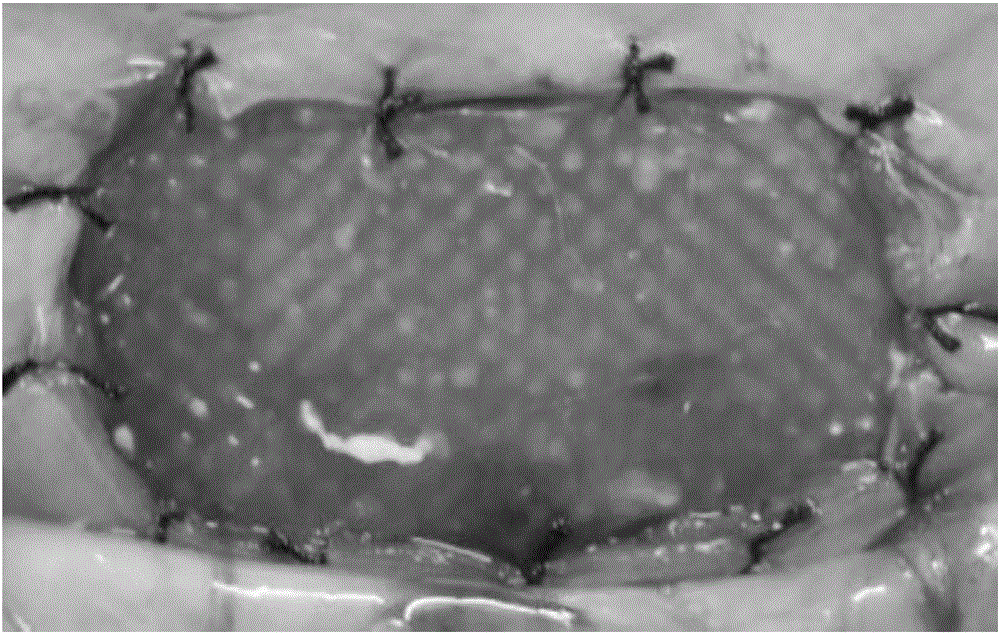

Examples

preparation example Construction

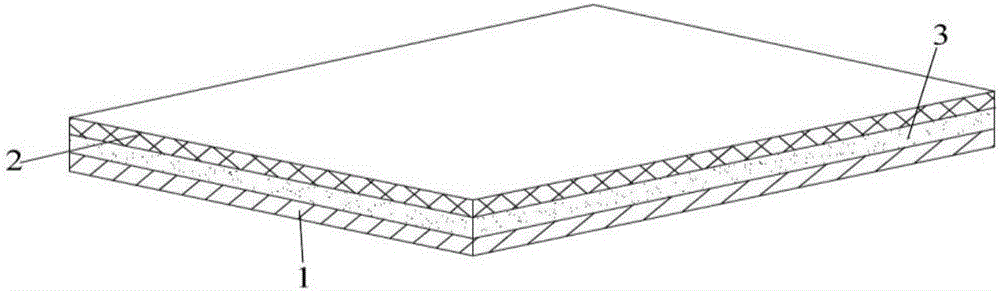

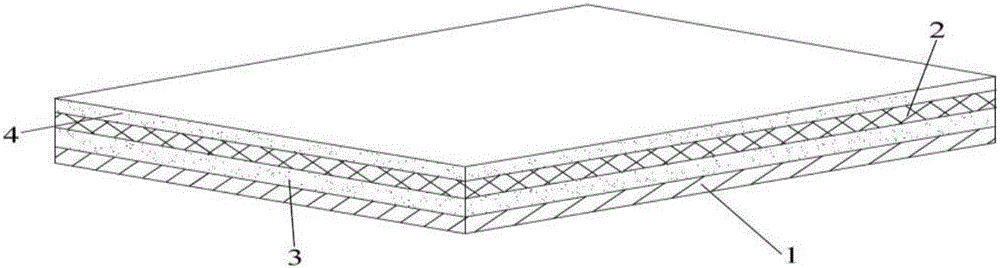

[0096] The present invention also provides a preparation method of the composite tissue repair patch according to the present invention, comprising:

[0097] Composite step: preparing an adhesive material solution, and compounding the nanofiber membrane and the woven mesh with the adhesive material solution to obtain the composite tissue repair patch; preferably, by freeze-drying process or coating process or casting The process is to compound the nanofiber film and the woven mesh with the adhesive material solution.

[0098] According to the method of the present invention, wherein the molecular weight of the adhesive material and / or the concentration of the adhesive material solution are adjusted so that the adhesive material solution overflows from the pores of the woven mesh and A layer of anti-adhesion solution was formed on the side opposite to the side where the nanofibrous membrane was located. Preferably, by controlling the molecular weight of the adhesive material a...

Embodiment 1

[0138]

[0139] Polylactic acid (PLLA) was dissolved in hexafluoroisopropanol solution, wherein the concentration of polylactic acid was 5% (g / mL), stirred and dissolved to obtain a uniform polymer solution. Place the polymer solution in the electrospinning syringe, adjust the rate of the micro-injection pump to 8mL / h, adjust the voltage of the high voltage generator to 15kV, adjust the receiving distance of the receiving device to 15cm, and perform electrospinning. The electrospinning was turned off after the layer thickness reached 0.15 mm, and the nanofibrous membrane was obtained.

[0140]

[0141] Weigh 20g of hydroxyethyl cellulose and dissolve it in 100mL of purified water, add 0.8g of calcium chloride, and adjust the pH of the solution to 4 with acetic acid, stir and dissolve evenly; add 0.8mL of glutaraldehyde solution (mass concentration is 25%), and control The reaction temperature is 65° C., and the modification treatment is carried out for 60 minutes; an adhes...

Embodiment 2

[0146]

[0147] Poly DL-lactic acid (PDLLA) was dissolved in hexafluoroisopropanol solution, wherein the concentration of poly DL-lactic acid was 10% (g / mL), stirred and dissolved to obtain a uniform polymer solution. Place the polymer solution in the electrospinning syringe, adjust the rate of the micro-injection pump to 7mL / h, adjust the voltage of the high-voltage generator to 20kV, adjust the receiving distance of the receiving device to 15cm, and perform electrospinning. The electrospinning was turned off after the layer thickness reached 0.2 mm, and the nanofibrous membrane was obtained.

[0148]

[0149] Weigh 10g of sodium carboxymethylcellulose and dissolve it in 100mL of purified water, add 0.5g of calcium chloride, adjust the pH of the solution to 3 with dilute hydrochloric acid, stir and dissolve evenly. Add 0.5 mL of glutaraldehyde solution (mass concentration: 25%), and control the reaction temperature at 70° C., and perform modification treatment for 40 min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com