Suspension liquid potash fertilizer, liquid compound fertilizer and preparation method and application of liquid potash fertilizer

A liquid and potash fertilizer technology, applied in liquid fertilizer, urea compound fertilizer, application and other directions, can solve the problems of unstable supply and high price, and achieve the effect of low production cost, low energy consumption, and no stratification of storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

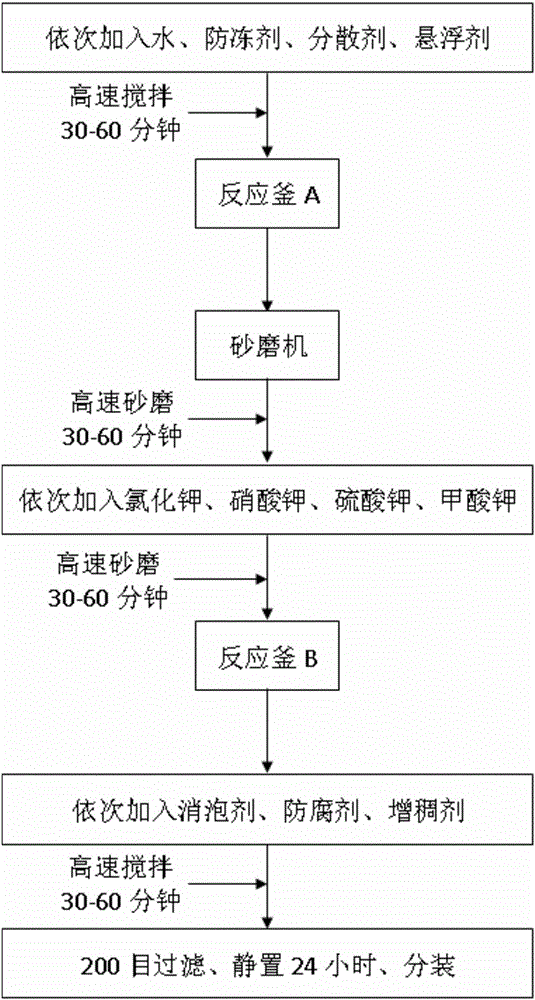

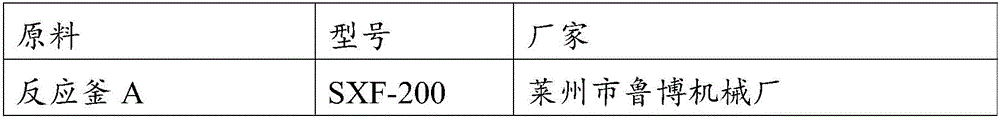

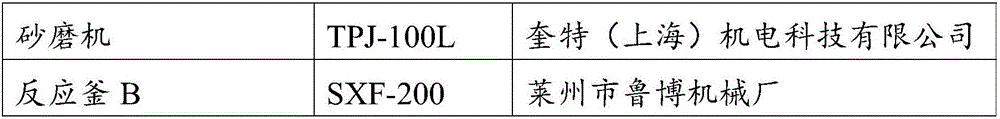

[0046] Meanwhile, the invention provides a method for preparing liquid potassium fertilizer. Wherein, in a preferred embodiment of the present invention, the preparation method of the high-concentration suspension type liquid potassium fertilizer comprises the following steps:

[0047] (1) According to the total amount of 100 parts, add 20-25 parts of water, 4-6 parts of antifreeze, 1.5-3 parts of dispersant, and 3-5 parts of suspending agent into the reaction kettle A under high-speed stirring conditions. , high-speed stirring for 40-50min, the speed of the stirrer is 800-1000 rpm, until all the above substances are dissolved and a homogeneous liquid is formed;

[0048] (2) Pump the liquid in the reactor A into the sand mill and carry out high-speed sand mill, the sand mill time is 40-50 minutes, the rotating speed of the sand mill is 2500-2800 rev / min, then take potassium chloride 4- 8 parts, 6-8 parts of potassium nitrate, 2-4 parts of potassium sulfate, 1-2 parts of potassi...

Embodiment 1

[0060] Embodiment 1 provides a kind of high-concentration suspension type liquid potassium fertilizer, according to 100 parts in total, the formula is as follows: 6 parts of potassium chloride, 8 parts of potassium nitrate, 3 parts of potassium sulfate, 3 parts of potassium fulvic acid, 47 parts of potassium formate 2 parts, 2 parts of ethylene glycol, 2 parts of urea, 1.5 parts of sodium hexametaphosphate, 2 parts of sodium bentonite, 1 part of lithium magnesium silicate, 0.3 parts of X-70500, 0.5 parts of CHS-5, 0.2 parts of xanthan gum, water 23.5 servings.

[0061] The preparation method of the high-concentration suspension type liquid potash fertilizer described in the present embodiment one, with reference to the attached figure 1 shown, including the following steps:

[0062] 1) Weigh 23.8kg of water and add it to reactor A. Under high-speed stirring, add 2kg of urea, 2kg of ethylene glycol, 1.5kg of sodium hexametaphosphate, 2kg of sodium bentonite, and 1kg of lithium...

Embodiment 2

[0077] Embodiment 2 provides a high-concentration suspension-type liquid potassium fertilizer. The formula is as follows: 7 parts of potassium nitrate, 0.5 parts of potassium fulvic acid, 60 parts of potassium formate, 3 parts of glycerol, and potassium pyrophosphate according to 100 parts in total. 1 part, 3 parts of sodium hexametaphosphate, 4 parts of sodium bentonite, 0.1 part of BS-163, 0.1 part of BS-126, 0.6 part of sodium benzoate, 0.4 part of hydroxyethyl cellulose, 20.3 parts of water.

[0078] The preparation method of the high-concentration suspension type liquid potash fertilizer described in the present embodiment two comprises the following steps:

[0079] 1) Weigh 20.3kg of water, add it to reactor A, and add 3kg of glycerol, 1kg of potassium pyrophosphate, 3kg of sodium hexametaphosphate, and 4kg of sodium bentonite successively under high-speed stirring conditions, and the speed of the agitator is 1200 rpm , and continue to stir for 40 minutes until all the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com