Rubber material for oil-resistant, high-temperature, and high-pressure gaskets and preparation method thereof

A technology of high temperature and high pressure resistance, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of ozone resistance, poor electrical insulation and cold resistance, good electrical conductivity, etc., to enhance wear resistance, improve resistance High temperature resistance, the effect of improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

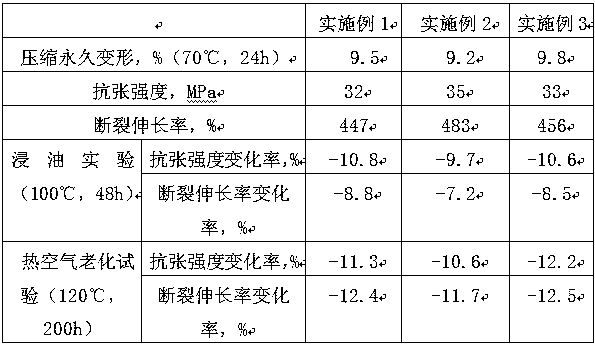

Examples

Embodiment 1

[0014] A rubber material for oil-resistant, high-temperature, and high-pressure gaskets, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 70, neoprene rubber 20, vinylidene fluoride / chlorotrifluoroethylene copolymer 18, epoxy fatty acid methyl Esters 5, Di-Seconoctyl Phthalate 6, Anilinomethyltriethoxysilane 4, Pitch Oil 12, Zinc Dimethacrylate 4, 1,2,3,4-Tetrahydroquinoline 2, Stearin Zinc acid 8, N, N-diethylaniline 1, rosin glyceride 4, epoxy soybean oil 3, aluminum phosphite 10, dicyclohexyl peroxydicarbonate 7, basic lead silicate 6, basic magnesium chloride Whisker 4, nano calcium carbonate 24, silicon boride 7, precipitated white carbon black 8, white jade powder 10, sodium antimonate 8, dibenzothiazole disulfide 1, sulfur 2.

[0015] A method for preparing a rubber material for an oil-resistant, high-temperature, and high-pressure gasket, comprising the following steps:

[0016] (1) Put nitrile rubber, neoprene, vinylidene flu...

Embodiment 2

[0020] A rubber material for oil-resistant, high-temperature, and high-pressure gaskets, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 80, neoprene rubber 25, vinylidene fluoride / chlorotrifluoroethylene copolymer 20, epoxy fatty acid methyl Esters 6.5, Di-Se-Octyl Phthalate 7, Anilinomethyltriethoxysilane 4.5, Bitumen Oil 14, Zinc Dimethacrylate 5, 1,2,3,4-Tetrahydroquinoline 3, Stearin Zinc acid 8.5, N, N-diethylaniline 1.5, rosin glyceride 5.5, epoxidized soybean oil 4, aluminum phosphite 12, dicyclohexyl peroxydicarbonate 8, basic lead silicate 6.5, basic magnesium chloride Whisker 5, nano calcium carbonate 26, silicon boride 8, precipitated white carbon black 9, white jade powder 11, sodium antimonate 9, dibenzothiazole disulfide 1.5, sulfur 2.5.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A rubber material for oil-resistant, high-temperature, and high-pressure gaskets, which is prepared from the following raw materials in parts by weight (kg): nitrile rubber 90, chloroprene rubber 30, vinylidene fluoride / chlorotrifluoroethylene copolymer 22, epoxy fatty acid formazan Esters 8, Di-sec-octyl phthalate 8, Anilinomethyltriethoxysilane 5, Pitch oil 16, Zinc dimethacrylate 6, 1,2,3,4-tetrahydroquinoline 4, Stearin Zinc acid 9, N, N-diethylaniline 2, rosin glyceride 7, epoxy soybean oil 5, aluminum phosphite 14, dicyclohexyl peroxydicarbonate 9, basic lead silicate 7, basic magnesium chloride Whisker 6, nano calcium carbonate 30, silicon boride 9, precipitated white carbon black 10, white jade powder 12, sodium antimonate 10, dibenzothiazole disulfide 2, sulfur 3.

[0024] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com