Complex microbial inoculant used for degrading waste water rich in surfactant and preparation method thereof

A technology of surfactant and compound bacterial agent, applied in microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the fluctuation of surfactant content, the difficulty of microorganism degradation, and the insignificant treatment effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned composite bacterial agent for degrading wastewater rich in surfactants requires independent cultivation of four bacterial powders. Since each bacterial species belongs to Bacillus, the preparation process of each bacterial powder is the same, specifically including the following steps:

[0036] (1) Inoculate a single strain on a slant for cultivation;

[0037] The slant medium is: tryptone 10g / L, yeast extract powder 5g / L, sodium chloride 10g / L, agar powder 15g / L, pH natural, sterilized at 121°C for 20 minutes;

[0038] The cultivation process is as follows: after inoculation, it is placed in a biochemical incubator at 32-35° C. for 24-30 hours.

[0039] (2) Inoculate the product of step (1) into the seed shake flask for cultivation;

[0040] The seed shake flask medium is: tryptone 10g / L, yeast extract powder 5g / L, sodium chloride 10g / L, pH natural, sterilized at 121°C for 20 minutes;

[0041] The cultivation process is a...

Embodiment 1

[0055] Wastewater COD is 3850mg / L, which contains non-ionic surfactant 580mg / L, contains anionic surfactant 1390mg / L, pH value is 8.6, the specific implementation steps are as follows:

[0056] (1), using a 1L measuring cylinder, add 900ml of waste water for later use.

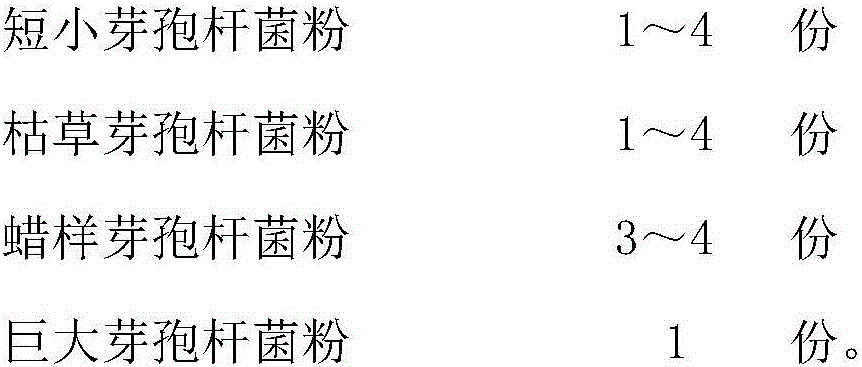

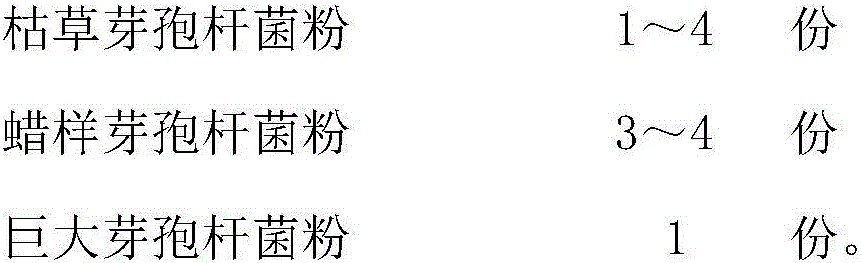

[0057] (2), take Bacillus pumilus (BNCC103925), Bacillus subtilis (BNCC188159), Bacillus cereus (BNCC338099) and Bacillus megaterium (BNCC190686) bacteria powder according to the ratio of 3:3:3:1 to get 10g altogether, then Add it into water containing 2% molasses to make the final volume 100ml, and control the temperature at 32-35°C while stirring continuously for 2-4 hours for later use.

[0058] (3) Add the bacterial solution in (2) into the graduated cylinder of (1) to establish a 1L wastewater degradation simulation system.

[0059] (4) Use an aeration device to continuously aerate (3), and control the dissolved oxygen in the system at 2-4 mg / L.

[0060] (5) After continuously aerating the waste water d...

Embodiment 2

[0065] Wastewater COD is 3054mg / L, which contains anionic surfactant 1792mg / L, pH value is 8.2, the specific implementation steps are as follows:

[0066] (1), using a 1L measuring cylinder, add 900ml of waste water for later use.

[0067] (2), take Bacillus pumilus (BNCC103925), Bacillus subtilis (BNCC188159), Bacillus cereus (BNCC338099) and Bacillus megaterium (BNCC190686) bacteria powder according to the ratio of 1:4:4:1 to get 10g altogether, then Add it into water containing 2% molasses to make the final volume 100ml, and control the temperature at 32-35°C while stirring continuously for 2-4 hours for later use.

[0068] (3) Add the bacterial solution in (2) into the graduated cylinder of (1) to establish a 1L wastewater degradation simulation system.

[0069] (4) Use an aeration device to continuously aerate (3), and control the dissolved oxygen in the system at 2-4 mg / L.

[0070] (5) After continuously aerating the waste water degradation simulation system for 24-30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com