Optical fiber methane sensor based on graphene sensitivity enhancing and preparation method thereof

A methane sensor and graphene technology, applied in the field of sensors, can solve the problems of weak anti-electromagnetic interference, poor methane sensing, poor electrical insulation, etc., so as to improve the methane sensing and sensitivity, increase the conductivity, and increase the refractive index. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] This embodiment also provides a method for preparing a side-polished optical fiber, in which a section of a single-mode optical fiber is

[0043] The 15mm area is polished to a place close to the fiber core. The grinding depth is monitored by a filament measuring instrument. The single-mode fiber is immersed in a test tube filled with alcohol and cleaned by an ultrasonic cleaner to ensure that the surface of the area before coating the film is clean. .

[0044] Preferably, the tin salt is tin tetrachloride.

[0045] Preferably, the alcohol is isopropanol.

[0046] This embodiment also provides an application of the graphene-based optical fiber methane sensor in methane.

[0047] This embodiment also provides an application of the graphene-based optical fiber methane sensor in mine gas leakage monitoring.

[0048] Its sensing principle is:

[0049] Tin dioxide is an n-type semiconductor, which is conducted by electrons. Light waves propagate in it, and there is absor...

Embodiment

[0063] 1. Preparation of side-polished optical fiber

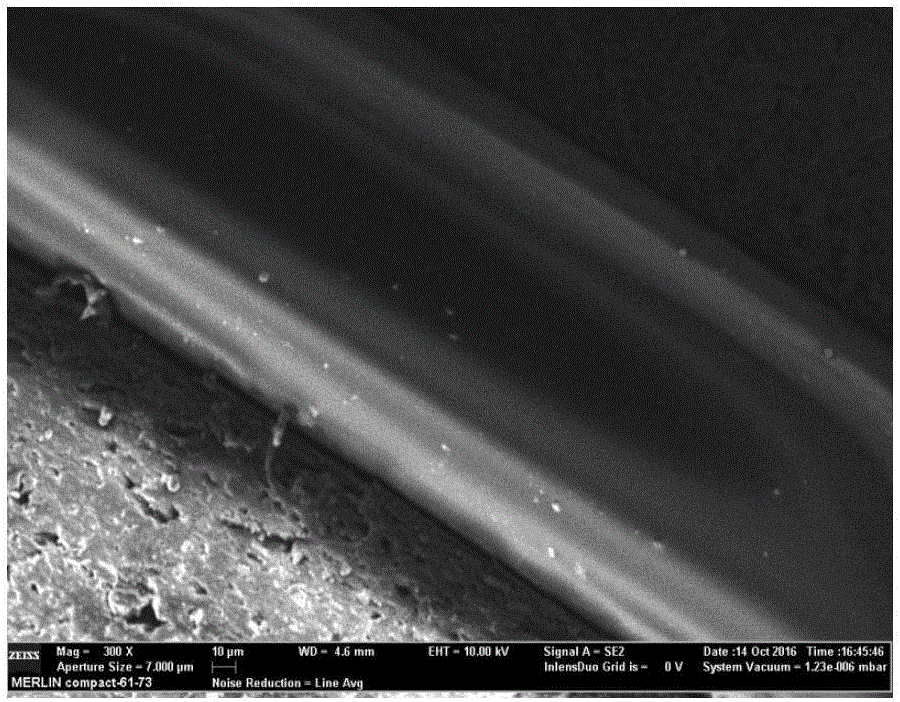

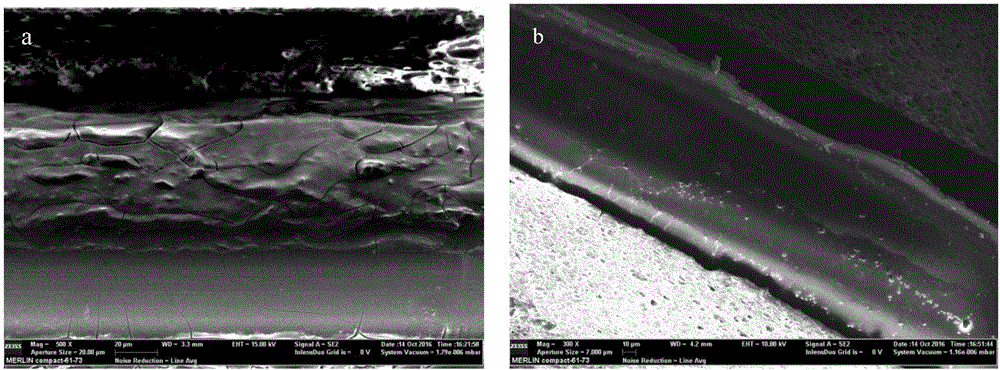

[0064] A single-mode optical fiber with a core diameter of 9 μm and a cladding diameter of 12 μm was used to polish a 15 mm section of the optical fiber by the wheel polishing method until it was close to the core. The grinding depth was monitored by a filament measuring instrument. Dip the optical fiber into a test tube filled with alcohol, and clean it with an ultrasonic cleaner to ensure that the surface of the area before coating the film is clean. The prepared side-polished optical fiber is as follows: figure 1 shown.

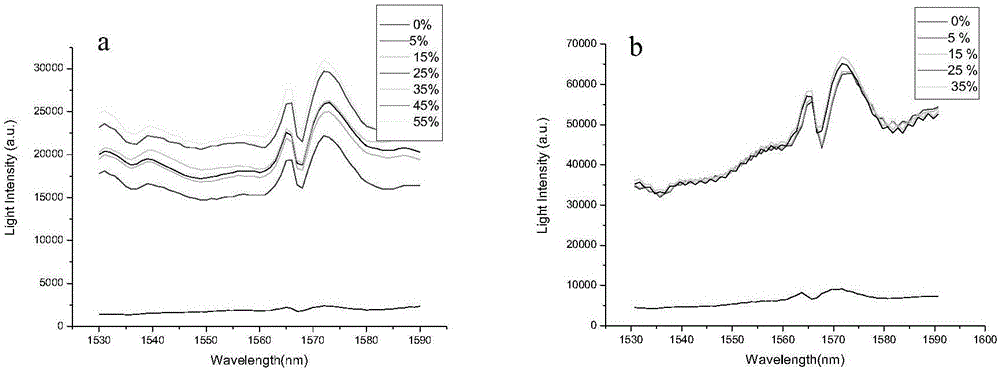

[0065] 2. Preparation of fiber optic methane sensor based on graphene sensitization

[0066] Weigh SnCl 4 ·5H 2 O, dissolved in 50mL of isopropanol to make a solution with a concentration of 0.05mol / L, one part of which was added with 0.05g of graphene. Place the prepared solution on a magnetic stirrer at room temperature and stir for 4 hours, then remove it and let it stand Aging for 24h. Apply t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com