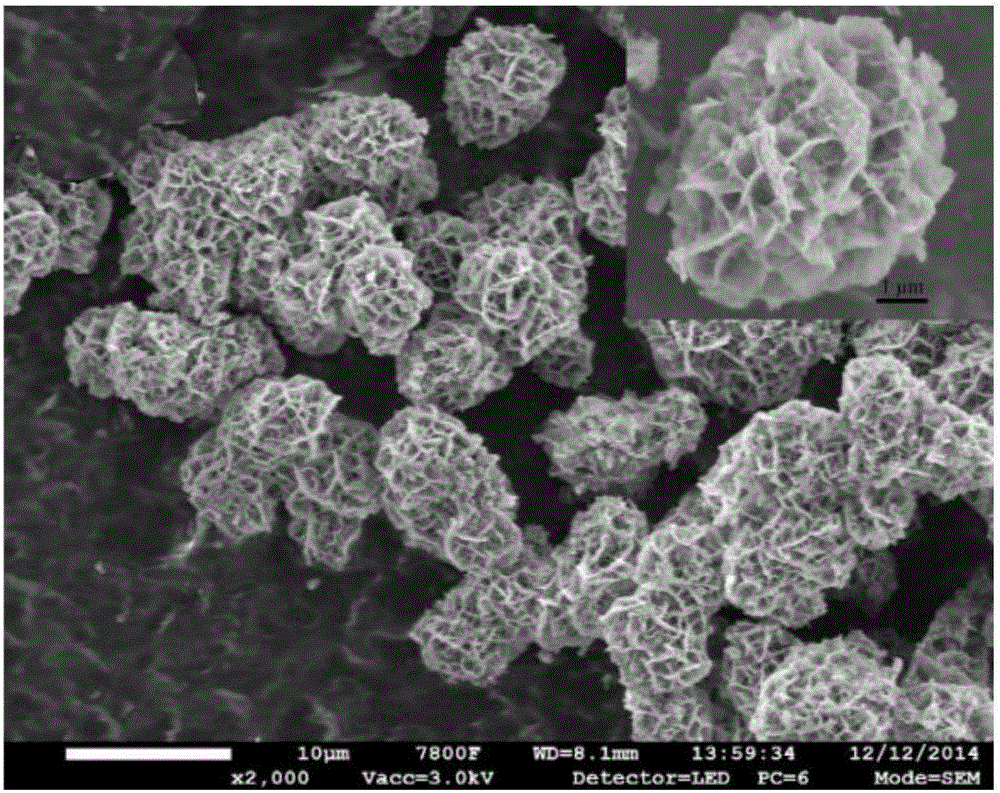

Flower ball-shaped nickel/cobalt oxide oxygen evolution catalyst, and preparation method and application thereof

A technology of cobalt oxides and catalysts, which is applied in the flower-shaped nickel/cobalt oxide oxygen evolution catalyst and its preparation and application fields. The effect of uniformity, good dispersion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] preparation:

[0038] (1) Mixing of precursor solution: Take 30mL of n-hexane in a 50mL beaker; add 1.5g of dodecyltrimethylammonium bromide (CTAB) to the mixed solution under vigorous stirring, and stir for 15min; After the alkyltrimethylammonium bromide was dissolved, 2 mL of 0.5M aqueous urea solution was added dropwise to the solution, and the stirring was continued for 10 min until a transparent solution was obtained. Quantitatively take 0.5M CoSO 4 solution and 0.5M NiSO 4 solution, mix the two evenly, add dropwise to the transparent solution obtained before, and stir vigorously for 30 minutes;

[0039] (2) Hydrothermal reaction: transfer the solution of (1) to a 50mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 150°C in a blast drying oven for 10 hours, and the hydrothermal kettle is cooled with the furnace to prepare nickel-cobalt hydroxide . Wash by centrifugation for 3 to 5 times, and dry in vacuum for 8 hours.

[0040] (3) Roasting:...

Embodiment 2

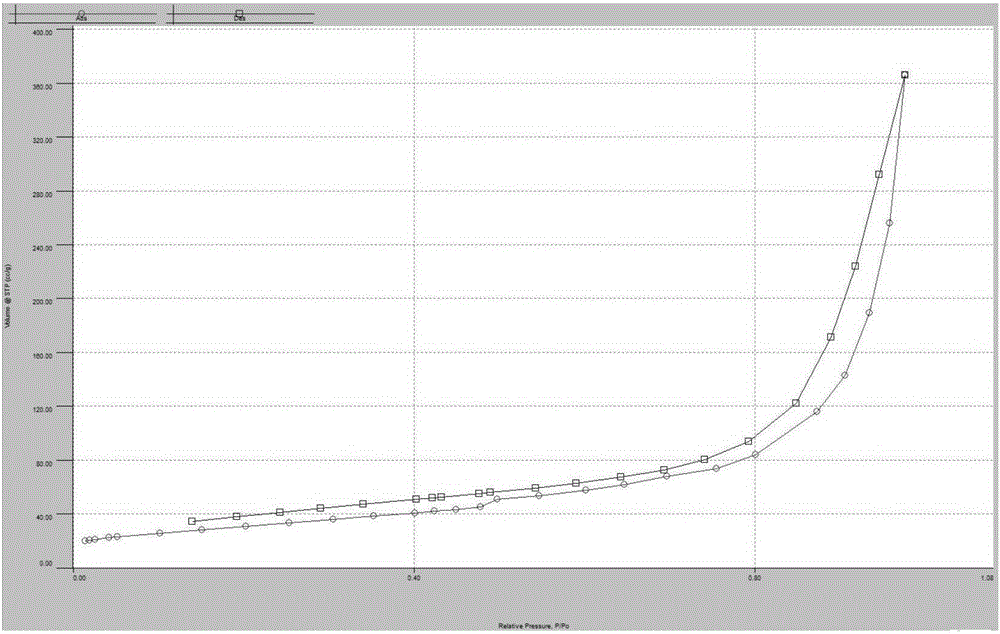

[0043] Find through BET test, the specific surface area of the spherical nickel-cobalt oxide prepared in example 1 reaches 110m 2 / g.

Embodiment 3

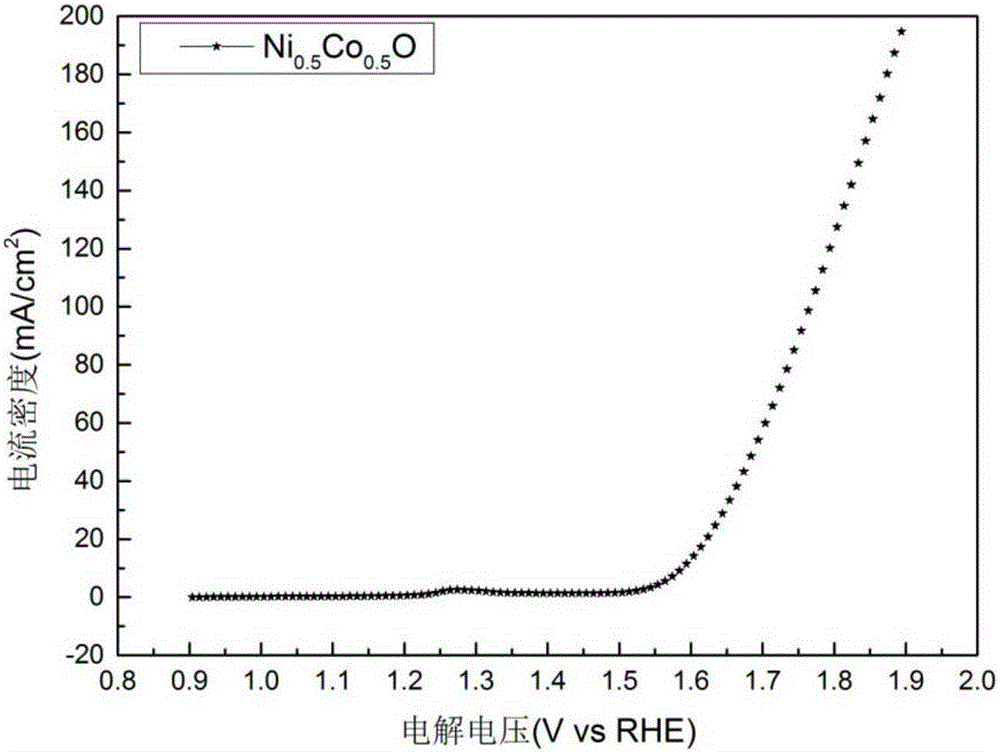

[0045] Take the same preparation process as in Example 1, change the precursor solution to 0.1M CoSO 4 solution and 0.9M NiSO 4 The half-cell test procedure adopted by the solution is as described in Example 1, and the relevant test results are as follows Figure 4 shown. The Ni prepared by this method 7 co 3 (OH)x 10mA / cm in 1M KOH electrolyte solution 2 The potential at the electrolysis current density is 1.612V (vs.RHE).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com