A kind of denitrification catalyst and preparation method thereof

A denitrification catalyst and precursor technology, applied in chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of unstable activity and unbalanced active centers, and achieve stable catalyst activity. The effect of uniform dispersion and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

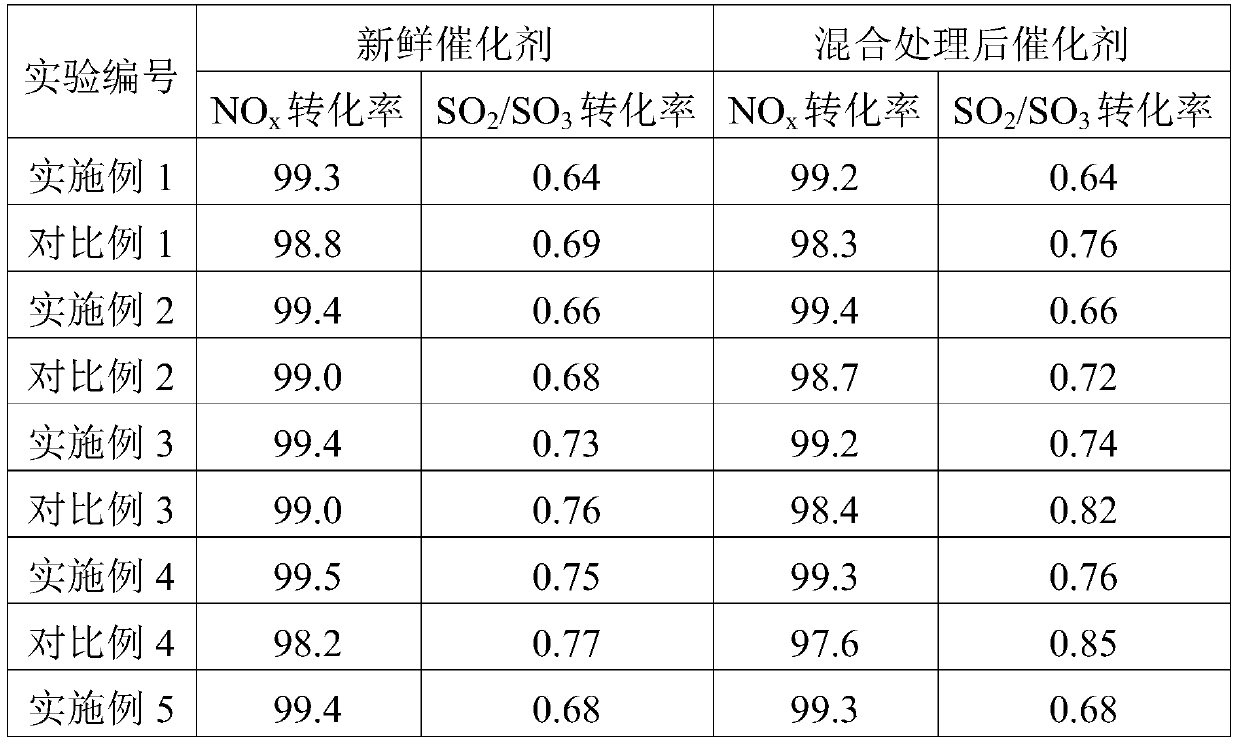

Embodiment 1

[0040] will contain TiO 2 500g of titanyl sulfate is dissolved in the sulfuric acid solution, adding 3 A total of 22.5g of ammonium paratungstate solution to form TiO 2 It is a 35g / L mixed solution. After ultrasonic vibration for 2 hours, gradually add ammonia water to adjust the pH value to 9.5. After the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 50% from the washed material, and add V 2 o 5 A total of 4.5g of ammonium metavanadate solution was stirred and ultrasonically oscillated for 1.5h. After direct drying, it was roasted at 620°C for 8h; after roasting, the powder was mixed with WO 3 A total of 7.5g of ammonium metatungstate solution was made into a slurry with a water content of 30%. After stirring, 4g of polyethylene oxide was added, stirred for 40min, sealed and left for 24h, dried, and roasted at 620°C for 8h to obtain a denitration catalyst. The fresh catalyst obtained above and the catalyst mi...

Embodiment 2

[0044] will contain TiO 2 500g of titanyl sulfate is dissolved in the sulfuric acid solution, adding 3 A total of 22.5g of ammonium paratungstate solution to form TiO 2 It is a 30g / L mixed solution. After ultrasonic vibration for 1.5h, gradually add ammonia water to adjust the pH value to 10. After the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 50%, and add with V 2 o 5 A total of 4.5g of ammonium metavanadate solution was stirred and ultrasonically oscillated for 1.5h. After direct drying, it was roasted at 600°C for 8h; after roasting, the powder was mixed with WO 3 A total of 5g of ammonium metatungstate solution was used to make a slurry with a water content of 35%. After stirring, 3.5g of polyethylene oxide was added, stirred for 30 minutes, sealed and left for 16 hours, dried, and roasted at 600°C to obtain a denitration catalyst. The fresh catalyst obtained above and the catalyst mixed with the catal...

Embodiment 3

[0048] will contain TiO 2 500g of metatitanic acid was dissolved in the sulfuric acid solution, adding 3 A total of 20g of ammonium paratungstate solution to form TiO 2 It is a 30g / L mixed solution. After ultrasonic vibration for 1 hour, gradually add ammonia water to adjust the pH value to 9.5. After the precipitation is complete, filter and wash; then use deionized water to make a slurry with a water content of 45%, and add V 2 o 5 A total of 5g of ammonium metavanadate solution was stirred and ultrasonically oscillated for 1h. After direct drying, it was roasted at 550°C for 6h; after roasting, the powder was mixed with WO 3 A total of 5g of ammonium metatungstate solution was used to make a slurry with a water content of 30%. After stirring, 3g of polyethylene oxide was added, stirred for 30min, sealed and left for 20h, dried, and roasted at 550°C to obtain a denitration catalyst. The fresh catalyst obtained above and the catalyst mixed with the catalytic cracking vana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com