Method for removing ammonia nitrogen through three-dimensional pulse electrolysis

A technology of pulse electrolysis and ammonia nitrogen, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., to achieve the effect of low price, high efficiency removal and corrosion reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

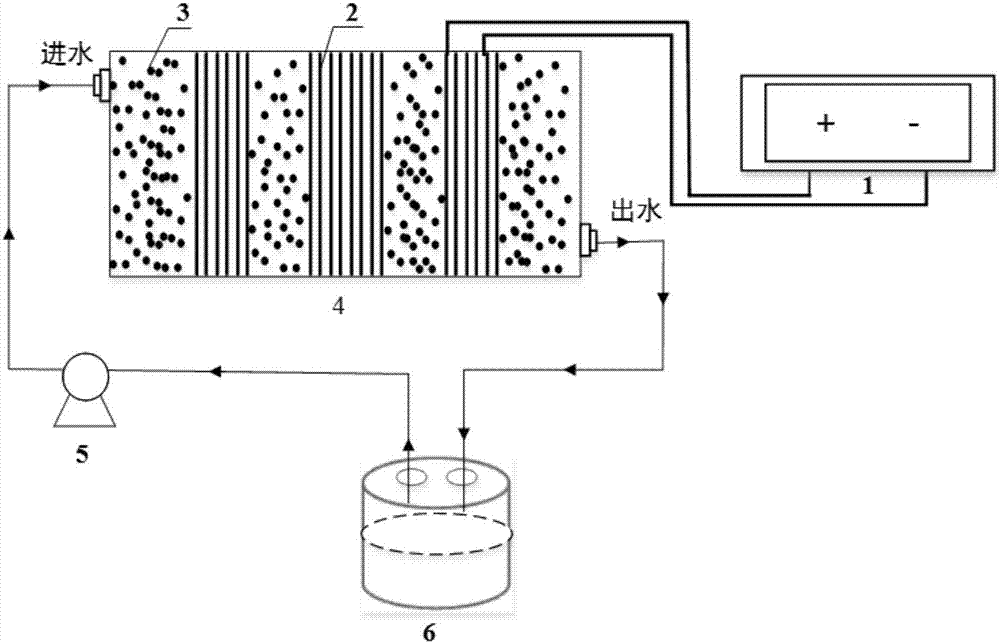

[0032] A method for removing ammonia nitrogen by three-dimensional pulse electrolysis is characterized in that it includes several sets of processing systems.

[0033] like figure 1 The single treatment system shown includes: power supply 1 , cathode and anode plates 2 , particle electrodes 3 , electrolytic tank 4 , constant current circulation pump 5 and circulation water container 6 .

[0034] The electrolytic cell 4, the constant-current circulating pump 5 and the circulating water container 6 are connected through relevant pipelines to form a closed loop. The constant current circulation pump 5 is connected to the water inlet end of the electrolytic cell 4 . The circulating water container 6 is connected to the water outlet of the electrolytic cell 4 .

[0035] Several groups of cathode and anode plates 2 are arranged inside the electrolytic cell 4 . The cathode and anode plates 2 are perpendicular to the water inlet direction and the water outlet direction of the elect...

Embodiment 2

[0040] A method for three-dimensional pulse electrolytic removal of ammonia nitrogen, characterized in that, using the system in Example 1, the following steps are carried out:

[0041] 1) Configure simulated ammonia nitrogen wastewater: the concentration range of ammonium sulfate is 318.6g / L, the concentration range of sodium sulfate is 10g / L, and the concentration range of sodium chloride is 125mg / L;

[0042] 2) The distance between the pole plates in the electrolytic cell 4 is 5mm, the total filling amount of coconut shell activated carbon is 130g, and the current density is 109.65mA / cm 2 , the flow range of the constant-current pump is 500-1000mL / h, measure 650mL of simulated distribution water in step 1), load pulse current electrolysis for 300min, and the removal rate of ammonia nitrogen in the simulated distribution water reaches 78.11%;

[0043] The anode plate is reticulated titanium plated ruthenium iridium (size: 57mm*76mm*1mm), and the cathode plate is reticulated ...

Embodiment 3

[0046] A method for three-dimensional pulse electrolytic removal of ammonia nitrogen, characterized in that, using the system in Example 1, the following steps are carried out:

[0047] 1) Configure simulated ammonia nitrogen wastewater: the concentration range of ammonium sulfate is 318.6g / L, the concentration range of sodium sulfate is 10g / L, and the concentration range of sodium chloride is 155mg / L;

[0048] 2) The distance between the pole plates in the electrolytic cell 4 is 5mm, the total filling amount of coconut shell activated carbon is 130g, and the current density is 109.65mA / cm 2 , the flow range of the constant-current pump is 500-1000mL / h, measure 650mL of simulated distribution water in step 1), load pulse current electrolysis for 300min, and the removal rate of ammonia nitrogen in the simulated distribution water reaches 98.01%;

[0049] The anode plate is reticulated titanium with ruthenium-plated iridium (size: 57mm*76mm*1mm), and the cathode plate is reticul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com