Titanium dioxide-based white PEEK composite material for oral cavity, and preparation method thereof

A technology of titanium dioxide and composite materials, which is applied in the fields of medical science, tissue regeneration, and prostheses, can solve the problems of structural permeability and wear resistance, insufficient color whiteness, and complicated preparation methods, etc., to achieve good appearance , good interface interaction, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

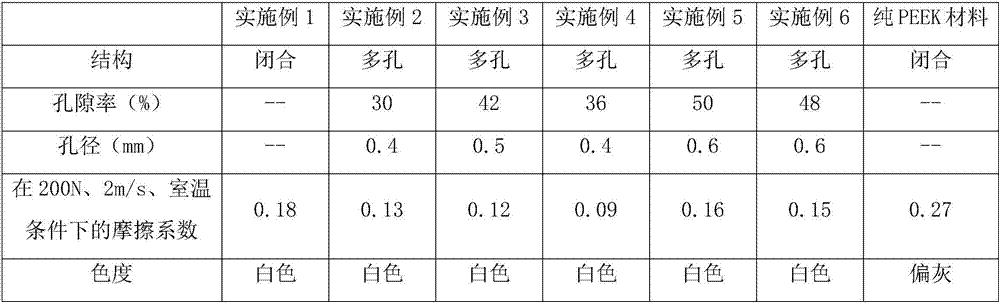

Examples

Embodiment 1

[0029] (1) Prepare the PEEK material into granules or powder with a particle size of less than 1 cm, spread it out, with a thickness of 2 cm, put it in an air circulation furnace, and place it in an environment of 100 ° C for 1 hour;

[0030] (2) Add titanium dioxide into absolute ethanol, ultrasonically disperse it, dropwise add silane coupling agent KH570 and concentrated ammonia water in sequence, heat and react at 60°C for 2h under nitrogen atmosphere, wash thoroughly with ethanol and water after the reaction, and bake. After drying, the titanium dioxide was spread out in an air circulation furnace and placed in an environment of 100 °C for 1 h.

[0031] (3) Mixing the PEEK material and the titanium dioxide in a mass ratio of 3:1 to obtain a mixture.

[0032] (4) The mixture is placed in the barrel of the extruder and fully mixed, and the temperature in the barrel is set between 400 ° C. After the temperature of the barrel is set, keep the temperature from fluctuating and ...

Embodiment 2

[0034] (1) Prepare the PEEK material into granules or powder with a particle size of less than 1cm, spread it out, with a thickness of 2.5cm, put it in an air circulation furnace, and place it in an environment of 150 ° C for 2 hours;

[0035] (2) Add titanium dioxide into absolute ethanol, ultrasonically disperse it, dropwise add silane coupling agent KH570 and concentrated ammonia water in sequence, heat and react at 60°C for 2h under nitrogen atmosphere, wash thoroughly with ethanol and water after the reaction, and bake. Dry, and then spread the titanium dioxide in an air circulation furnace and place it in an environment of 200 ° C for 1-4 hours;

[0036] (3) mixing the PEEK material and titanium dioxide according to a mass ratio of 4:1, and then adding a sodium chloride pore-forming agent with a mass fraction of 10% to obtain a mixture.

[0037] (4) The mixture is placed in the barrel of the extruder and fully mixed, and the temperature in the barrel is set between 400 °...

Embodiment 3

[0039] (1) Prepare the PEEK material into granules or powder with a particle size of less than 1cm, spread it out with a thickness of 3cm, put it in an air circulation furnace, and place it in an environment of 160 ° C for 1-4 hours;

[0040] (2) Add titanium dioxide into absolute ethanol, ultrasonically disperse it, dropwise add silane coupling agent KH570 and concentrated ammonia water in sequence, heat and react at 60°C for 2h under nitrogen atmosphere, wash thoroughly with ethanol and water after the reaction, and bake. Dry, and then spread the titanium dioxide in an air circulation furnace, and place it in an environment of 150 ° C for 2.5 hours;

[0041] (3) mixing the PEEK material and the titanium dioxide in a mass ratio of 5:1, and then adding a sodium chloride pore-forming agent with a mass fraction of 15% to obtain a mixture.

[0042](4) The mixture is placed in the barrel of the extruder and fully mixed, and the temperature in the barrel is set between 450 ° C. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com